- Location

- La Habra, CA

That's what I was afraid of. That he was in the mood for a little Asian, and he thought of me. :wierd:

I might know someone looking for a good fabricator!Looks great Jim.

When is the dash going back in? I am interested to see how it all fits together. Is the engine cage next?

That cage looks awesome Jim. After WF my Jeep is hopefully going down to HD Offroad for a cage, guess i'm gonna keep it all internal. I think 32's and 3" of lift would look sorta goofy with a halo on top!

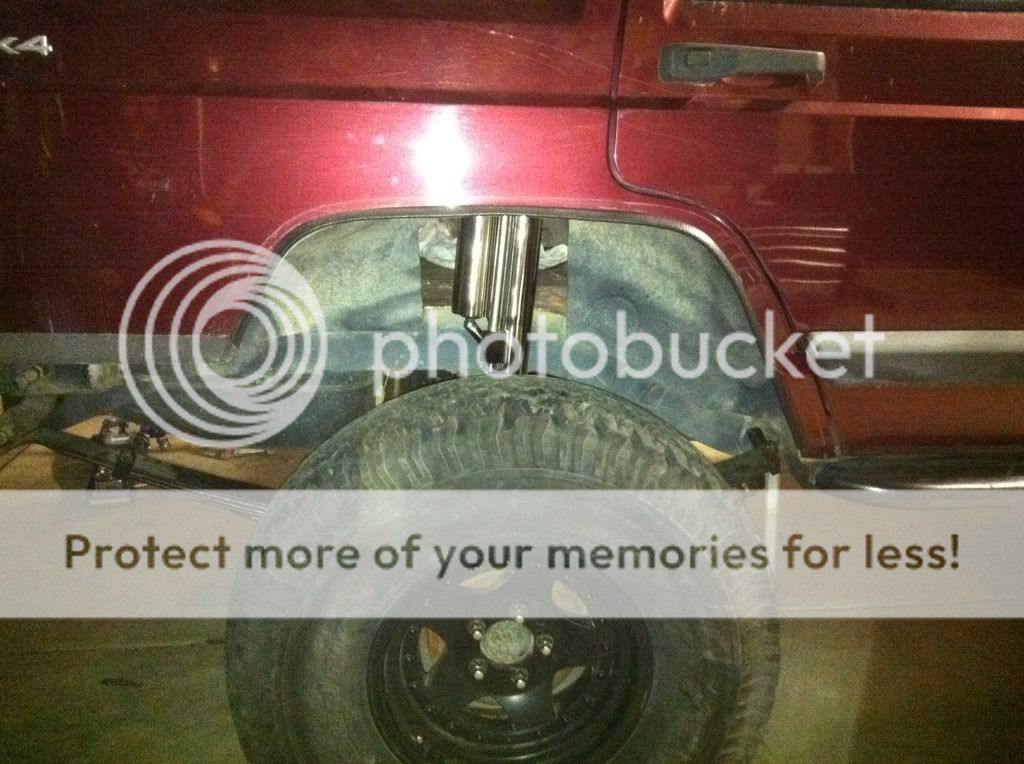

Not quite yet, I still need to buy WJ brakes/knuckles for it before I can put it under the front of the Jeep. Then we'll start on steering etc.That looks really good Jim! Got any pics of the frontend under it yet?

he recommends against it obviously and says it causes a nasty buck.