snail

NAXJA Forum User

- Location

- North Jersey

Little update just to keep this alive. What should have been done months ago is still dragging on. (i.e the rig is still on jackstands in my garage).

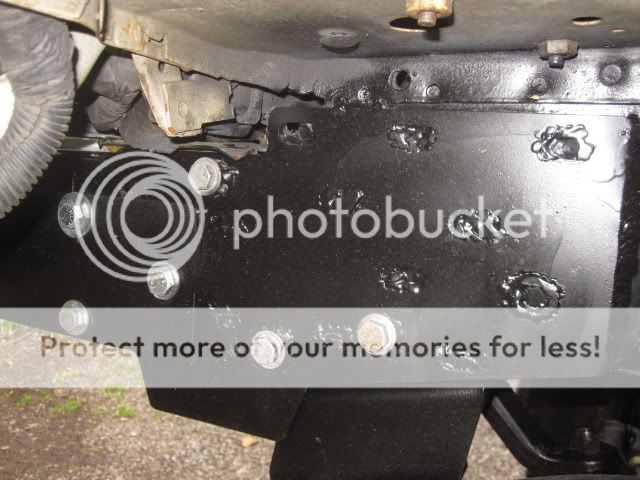

I've since acquired another front driveshaft to run in the rear and have rebuilt both, the D44 is all welded up and the disc swap just needs to be finished, and all the front suspension/steering components need to be installed. Otherwise the AA SYE went smoothly with some help from a buddy.

Quick notes/problems I ran into: some of these may seem juvenile to some of you, but hey.

-only 2000-2001 (LP) D30 studs are actually longer and can be used for rear disc swaps

-packing too much grease into the ujoint caps (contrary to advice given in some website buildups), will cause the seals to crack when reinstalling the caps/joints

-buying front driveshaft centering ball replacement kits are useless (~$50) because the old balls are hard as fark to get out anyway and new centering yoke w/ new ball already installed can be acquired online for ~$30 dispite the fact that all my local autostores said that yoke is no longer available anywhere

I've since acquired another front driveshaft to run in the rear and have rebuilt both, the D44 is all welded up and the disc swap just needs to be finished, and all the front suspension/steering components need to be installed. Otherwise the AA SYE went smoothly with some help from a buddy.

Quick notes/problems I ran into: some of these may seem juvenile to some of you, but hey.

-only 2000-2001 (LP) D30 studs are actually longer and can be used for rear disc swaps

-packing too much grease into the ujoint caps (contrary to advice given in some website buildups), will cause the seals to crack when reinstalling the caps/joints

-buying front driveshaft centering ball replacement kits are useless (~$50) because the old balls are hard as fark to get out anyway and new centering yoke w/ new ball already installed can be acquired online for ~$30 dispite the fact that all my local autostores said that yoke is no longer available anywhere