- Location

- San Jose

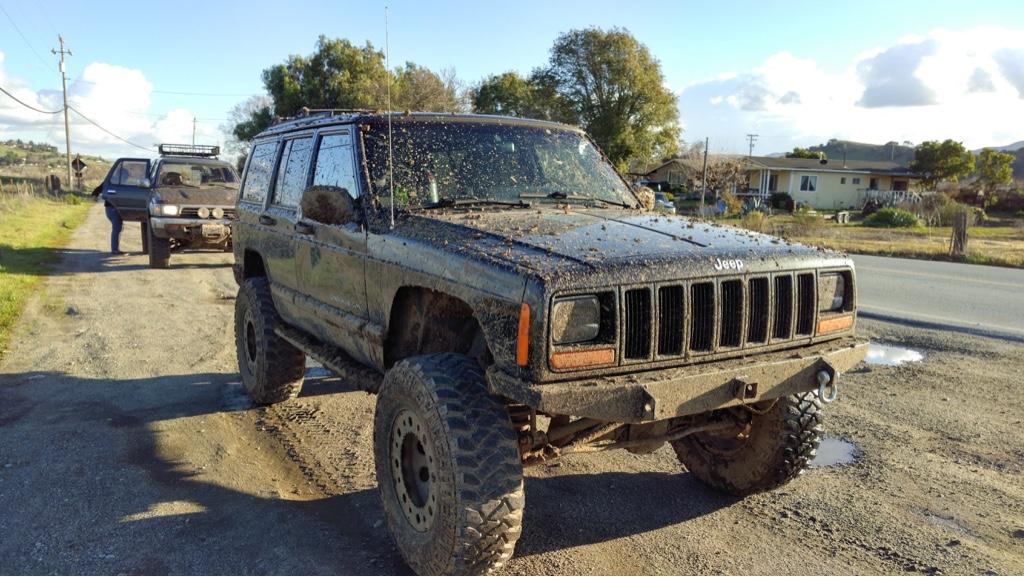

This thread serves as a timeline for the ongoing build of my 2000 Cherokee Classic. I’m writing this trying to remember all that has transpired so I’ll try to keep it straight forward. I’ll try and add lots of visuals to break up the words. Here we go.

I purchased it on black Friday of 2014 in really good shape and stock with 178k miles on the clock. At the time I was a student at SJSU and was using it as my daily driver. Before college, I had a buddy that had a Renix XJ and, to make a long story short, I caught the wheeling bug and had a hard on for Cherokees. Some friends from college would plan overlanding trips with their stock-ish rigs so I would tag along and camp. It’s a trip to go though and look at these older photos. I began looking into lifts and bigger tires and although it took what felt like a long time to pull the trigger on a lift, bumpers, tires, etc.., I felt like I had a well thought out plan.

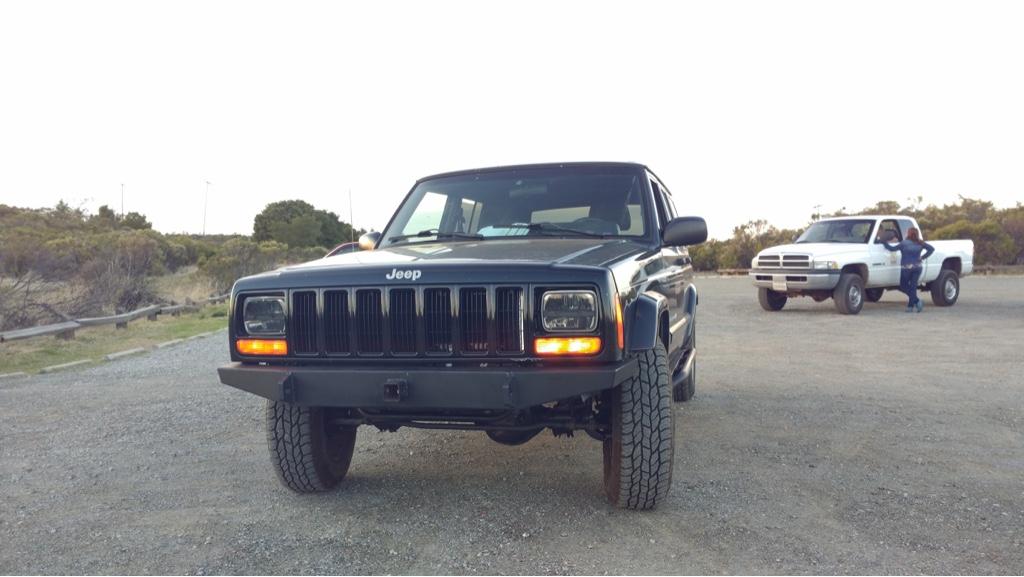

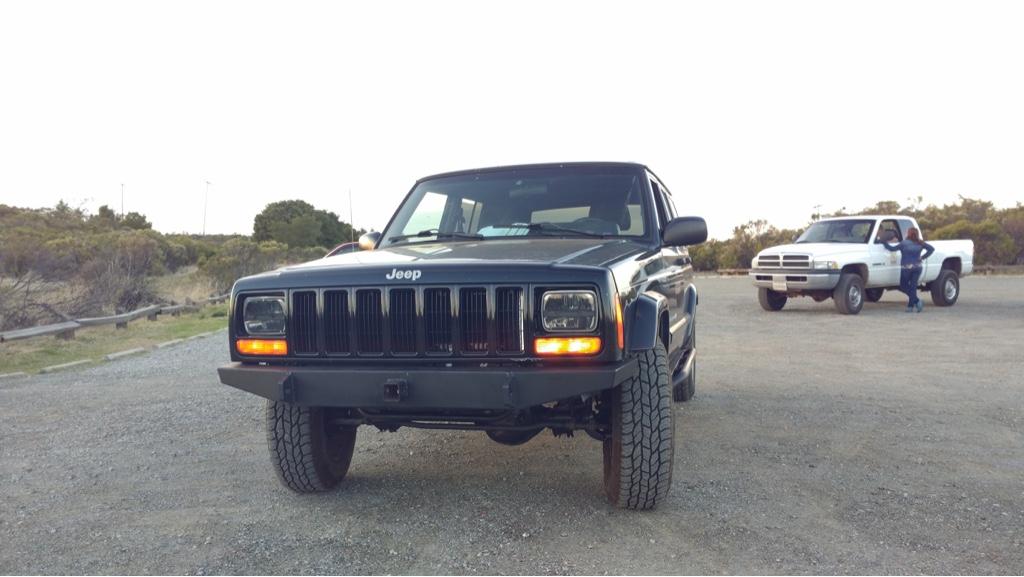

At the time, I was at SJSU and was working part time. I got my feet wet with a set of JCR DIY bumpers that I welded (my first MIG project) at the student machine shop at SJSU. Got those together and daily drove the jeep for a while like this.

The D30 under the jeep was low pinion so my first big project was to find a high pinion and build that to swap in while the jeep was still low.

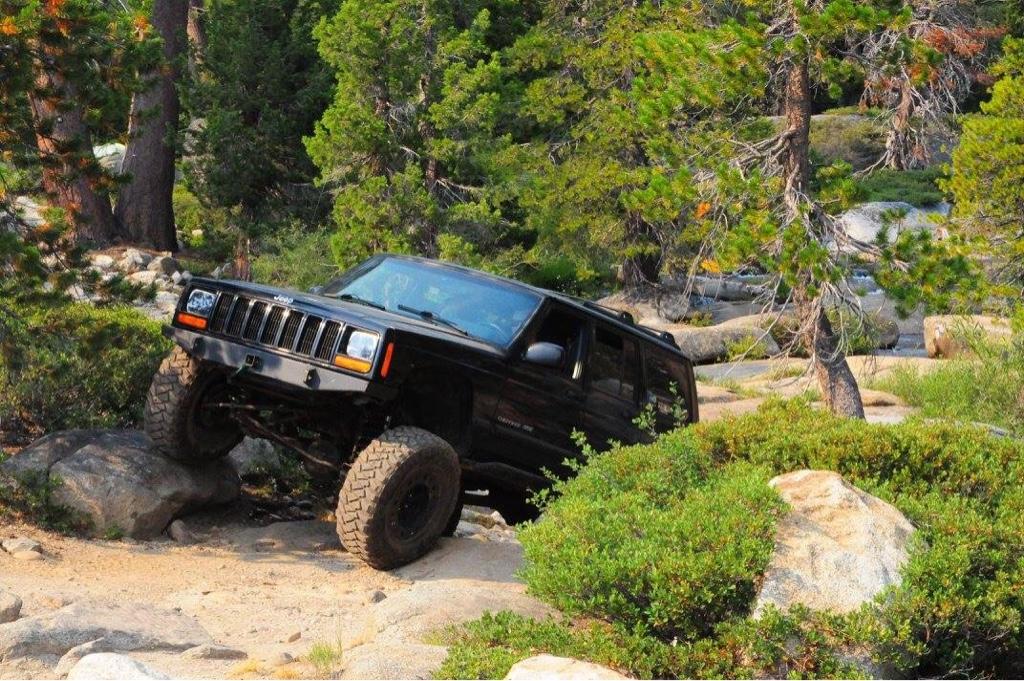

I figured when it was time for a lift, the front axle would be fresh, geared, and ready to go. I picked out 4.56 gears for the front and rear, a Richmond LockRite for the front, new Timken unit bearings, and spicer ball joints. Built the HPD30 on a stand and eventually swapped the low pinion out on a Saturday. Keep in mind that this was a big step up for me in terms of planning out a build and was learning along the way. I had been tinkering with dirtbikes and other things here and there as well so I wasn’t a total newb. I had also picked out an ARB for the 8.25 and welded my own rear diff cover from BTF.

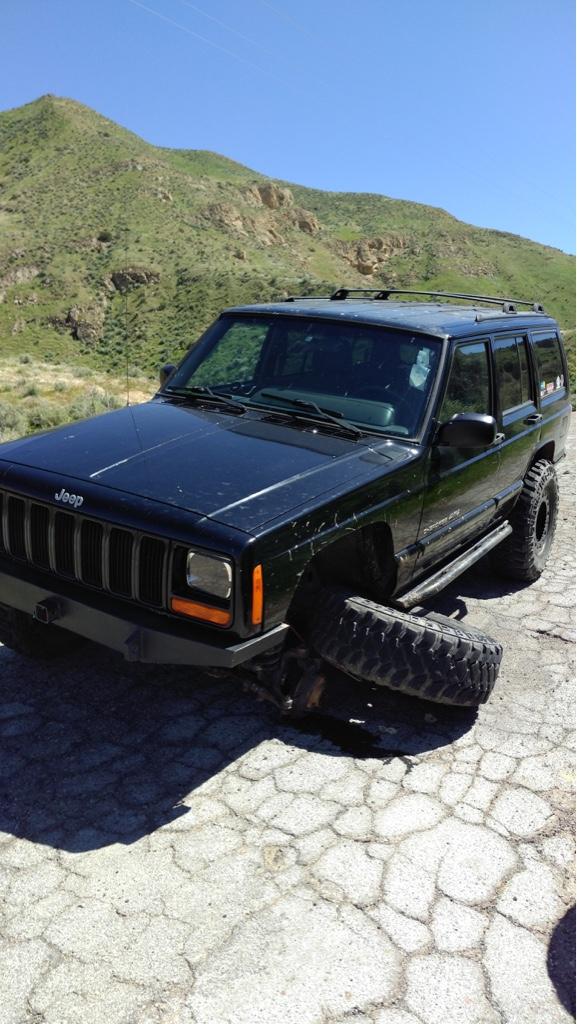

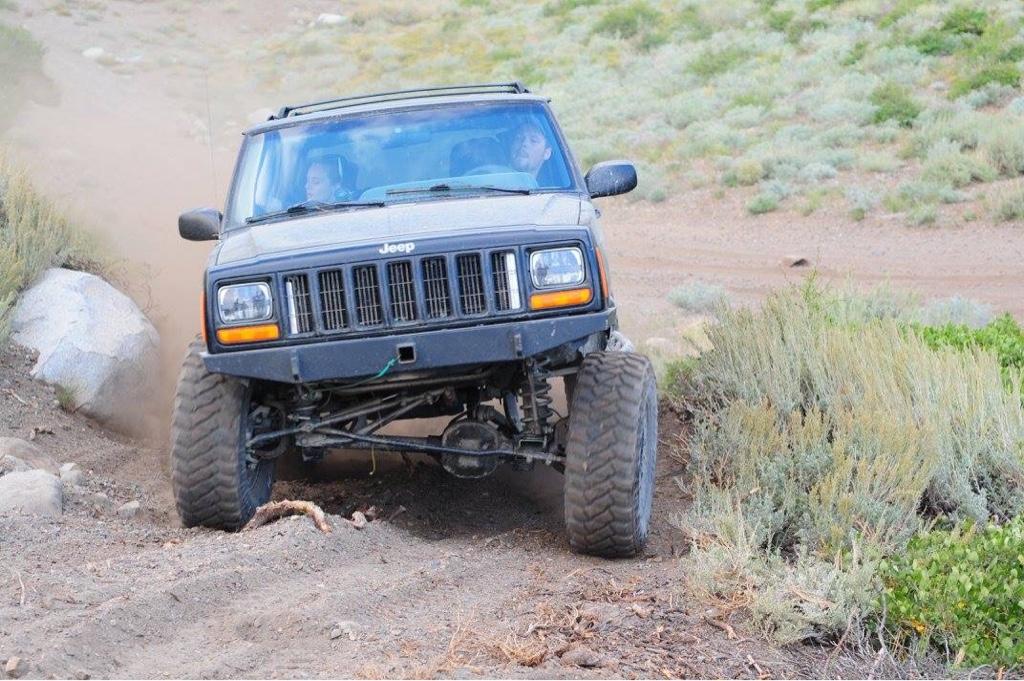

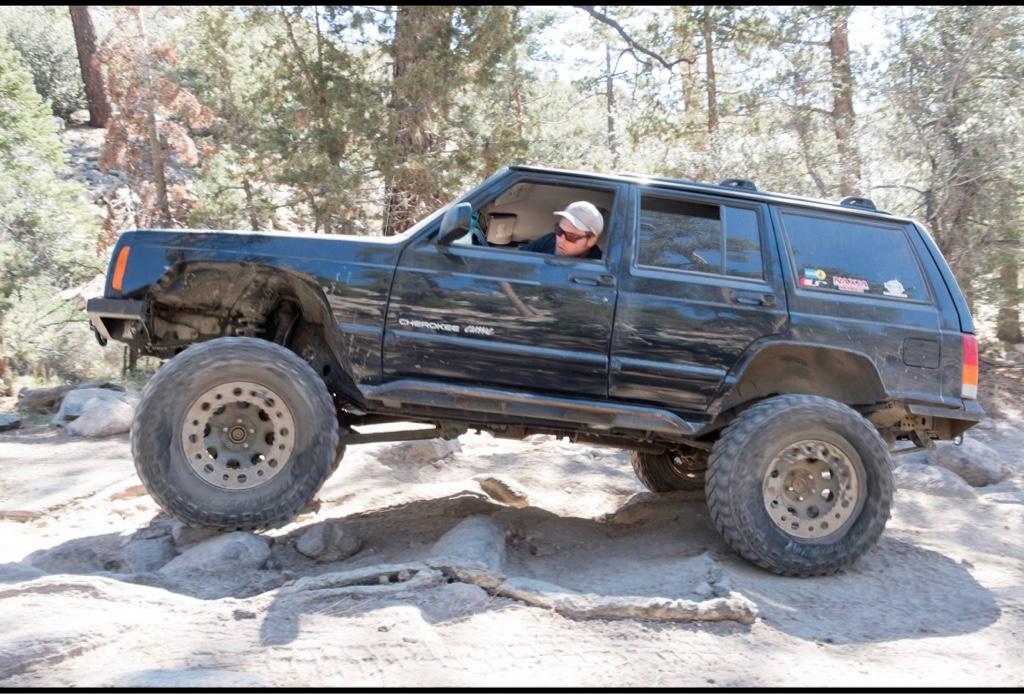

I had the jeep on stock suspension and tires for a few years and in October of 2016, I compiled a plethora of lift parts while working a part time internship with the state. The pay was worse but in the end it turned out to be a great stepping stone for my career. I finally saved up for a clayton radius arm (4.5”) lift with bilstien 5100’s, clayton double shear track bar bracket+track bar, jks quick disconnects, and clayton leaf springs.

My budget only allowed for steelies but with some help, I cad’d up some rock rings and had them water jet before TIG welding them to a cheap set of Soft 8s. Gives the Jeep a bead lock look and protects the valve stem. Also wasn’t something I saw on many jeeps so I gave it a shot.

Sent from my iPhone using Tapatalk

I purchased it on black Friday of 2014 in really good shape and stock with 178k miles on the clock. At the time I was a student at SJSU and was using it as my daily driver. Before college, I had a buddy that had a Renix XJ and, to make a long story short, I caught the wheeling bug and had a hard on for Cherokees. Some friends from college would plan overlanding trips with their stock-ish rigs so I would tag along and camp. It’s a trip to go though and look at these older photos. I began looking into lifts and bigger tires and although it took what felt like a long time to pull the trigger on a lift, bumpers, tires, etc.., I felt like I had a well thought out plan.

At the time, I was at SJSU and was working part time. I got my feet wet with a set of JCR DIY bumpers that I welded (my first MIG project) at the student machine shop at SJSU. Got those together and daily drove the jeep for a while like this.

The D30 under the jeep was low pinion so my first big project was to find a high pinion and build that to swap in while the jeep was still low.

I figured when it was time for a lift, the front axle would be fresh, geared, and ready to go. I picked out 4.56 gears for the front and rear, a Richmond LockRite for the front, new Timken unit bearings, and spicer ball joints. Built the HPD30 on a stand and eventually swapped the low pinion out on a Saturday. Keep in mind that this was a big step up for me in terms of planning out a build and was learning along the way. I had been tinkering with dirtbikes and other things here and there as well so I wasn’t a total newb. I had also picked out an ARB for the 8.25 and welded my own rear diff cover from BTF.

I had the jeep on stock suspension and tires for a few years and in October of 2016, I compiled a plethora of lift parts while working a part time internship with the state. The pay was worse but in the end it turned out to be a great stepping stone for my career. I finally saved up for a clayton radius arm (4.5”) lift with bilstien 5100’s, clayton double shear track bar bracket+track bar, jks quick disconnects, and clayton leaf springs.

My budget only allowed for steelies but with some help, I cad’d up some rock rings and had them water jet before TIG welding them to a cheap set of Soft 8s. Gives the Jeep a bead lock look and protects the valve stem. Also wasn’t something I saw on many jeeps so I gave it a shot.

Sent from my iPhone using Tapatalk

I suppose. I was able to reconnect with an old childhood friend at a San Jose meet up that was already part of the club. Best part was he lived 3 blocks from me.

I suppose. I was able to reconnect with an old childhood friend at a San Jose meet up that was already part of the club. Best part was he lived 3 blocks from me.