lessons learned so far:

this is basically my second welding gig, the first being the frame stiffeners 2 weeks ago.

i can that i learned finally today that for me it seems best to run the welder on lower feed speed, like 3, and keep the heat kinda high, except for the really thin parts of the body.

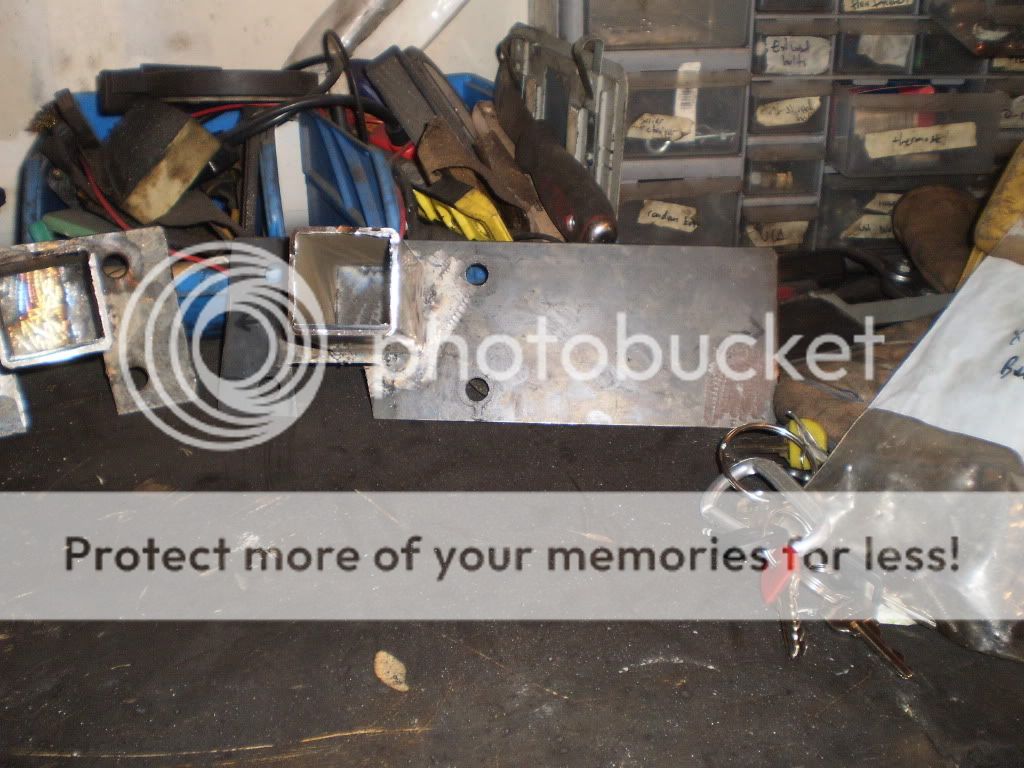

second, the materials needed for the rocker replacement:

(2) - 2x6 .095 wall x 62.5in (i bought these from S and K cut to 62.5in)

(4) -1x2 .120 wall x 11in ( i just bought 6 feet and cut it)

(2) - 1.5 .120 wall x 62.5 angle iron (i bought 4 since i was following erics build, but i didnt want to chop up my doors so i didnt go as high as he did)

its about 14in from the frame to the end of the 2x6, i originally had 2x2 going all the way to the end of the 2x6 on the bottom side, it looked like a rock anchor, so josh and i cut it off , and i picked up some 1x2 instead. higher profile .

also when welding the angle iron to the unibody , it is super thin, we didnt remove the carpet or anything so we were restricted to welding very little at time , and would let it cool, otherwise itd catch fire and we even caught the inside of the jeep on fire. have water ready!

i currently have 2 1x2 gussets off the stiffeners to the 2x6, i will eventually add 1 more per side but im sick of working on the rockers.

ill grind it all down and clean it for paint tomorrow and then start the rear bumper