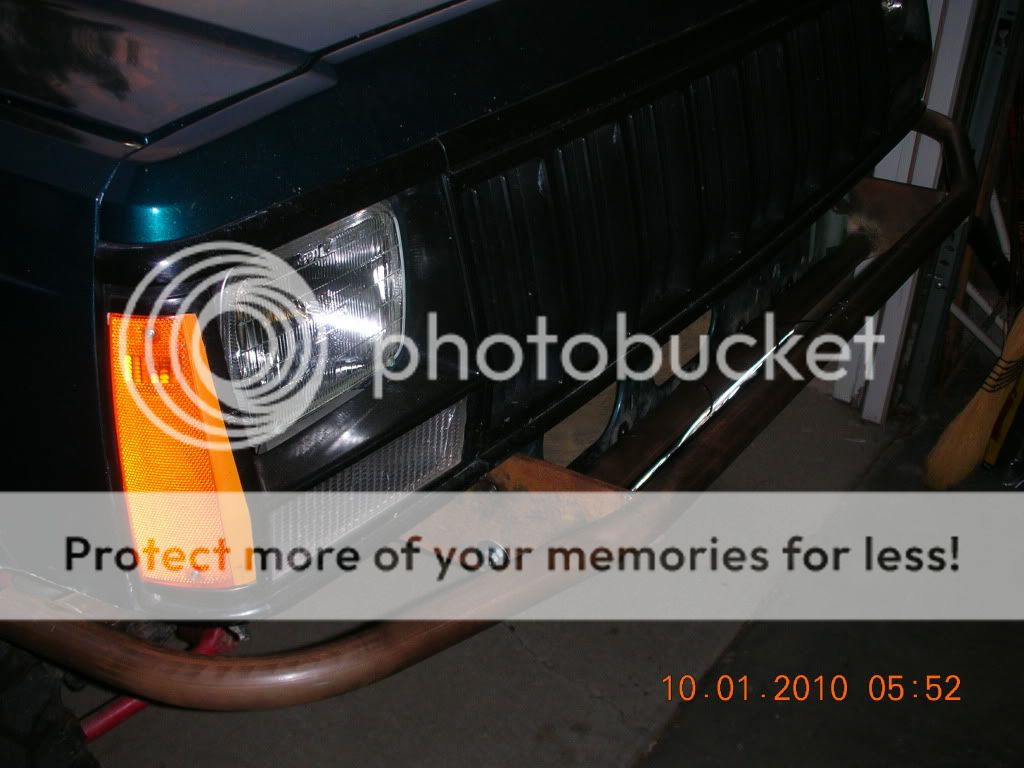

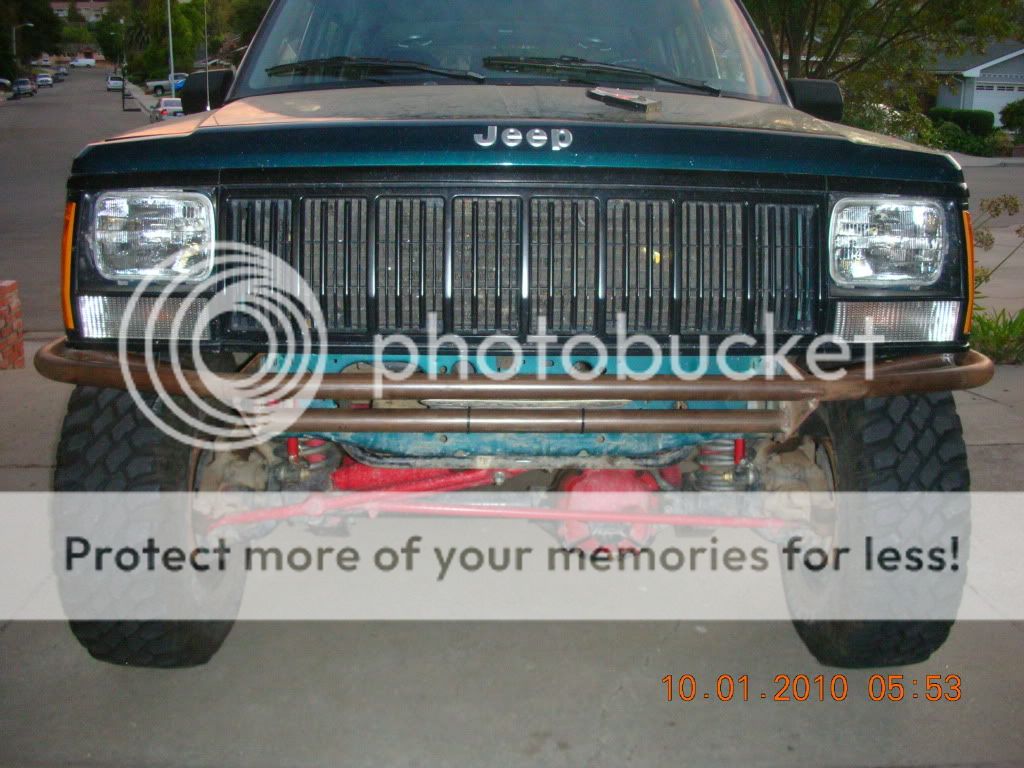

Finished up the bumper. I previously welded 3 vertical bars between the two horizontal bars for aesthetics and support, however, the lower tube (with 3 vertical pieces) was too close, and interfered with the crossmember. To fix this, I busted those 4 bars off with a BFH and re-notched the lower vertical pieces about 1/4" shorter. These new notches were much cleaner and straighter, and much much easier to weld.

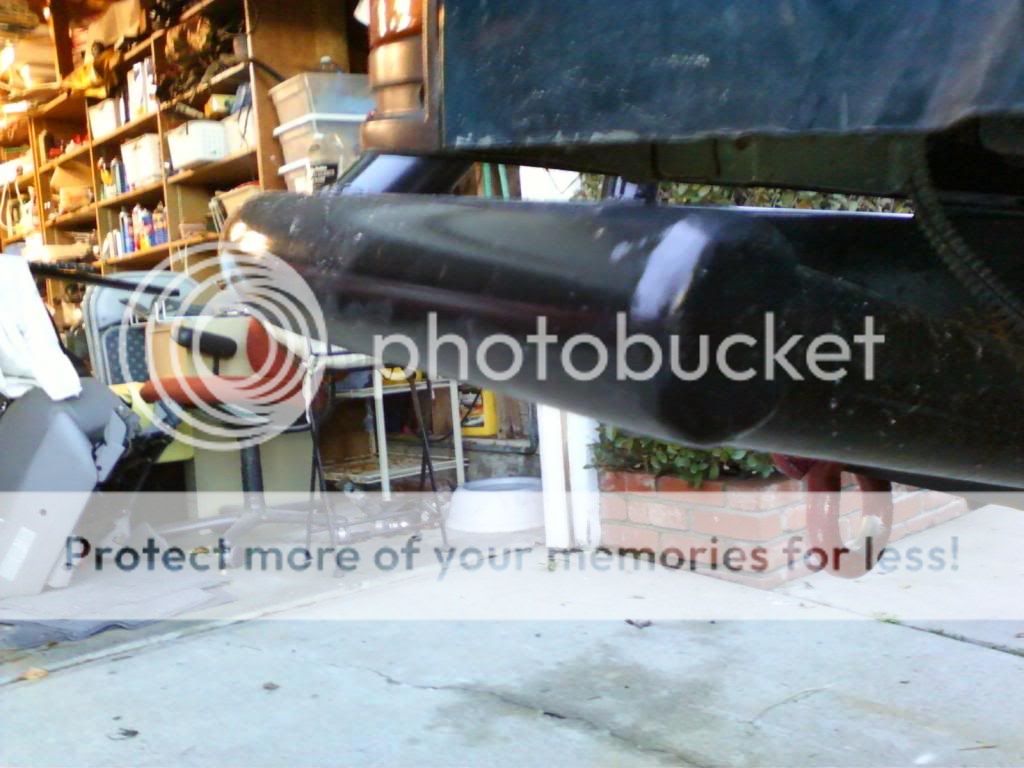

Next on the list was to cap the end of the bumpers. I previously cut out some circle with a 1.5" hole saw. Despite the hole in the middle of then, I fully welded them onto the end, and filled the drill hole.

Finished up the other side, and then went back and attacked it with the grinder/flap disk.

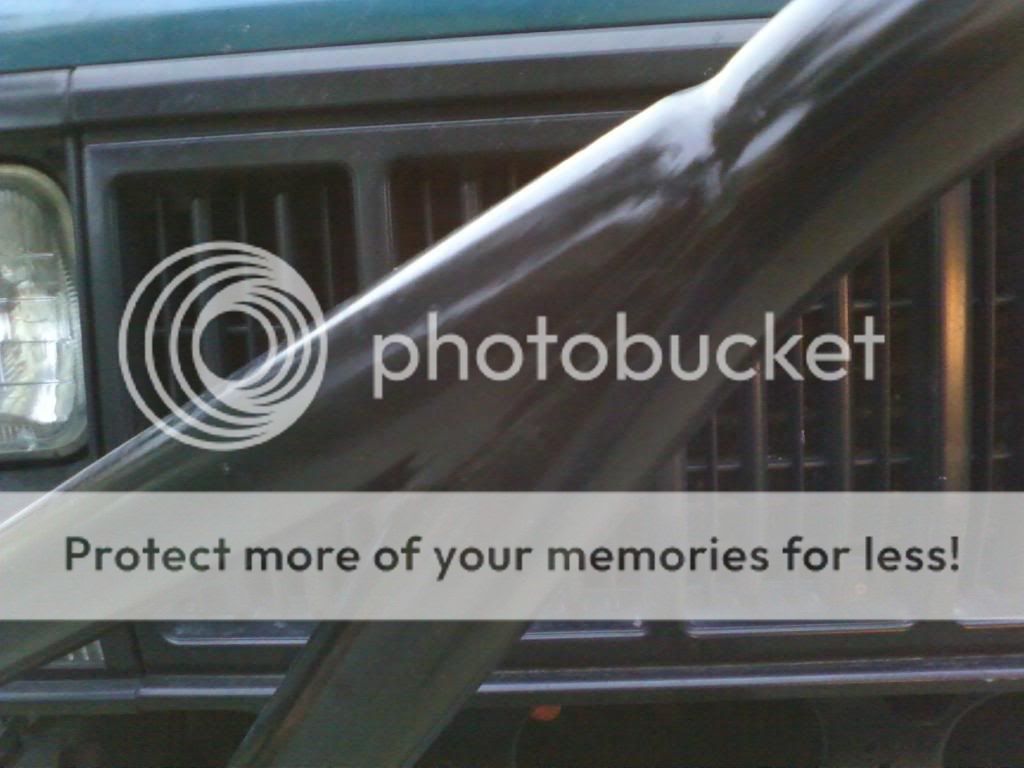

I wanted the transition from the hoop/stinger to the side support bars to be as clean as possible. To do this, I simply welded it up, and ground it smooth with the flap disk.

All welded up, before paint:

The next day, I took it outside and painted it up. Stupid me, I used some walmart spray paint I had laying around, and it is already peeling a tiny bit around the welds.

Then I drilled some 3/4" holes, and threw on some D-rings. I will go back some other time and weld a plate or two sandwiching the holes for more support (1/2" thick instead of 1/4" thick).

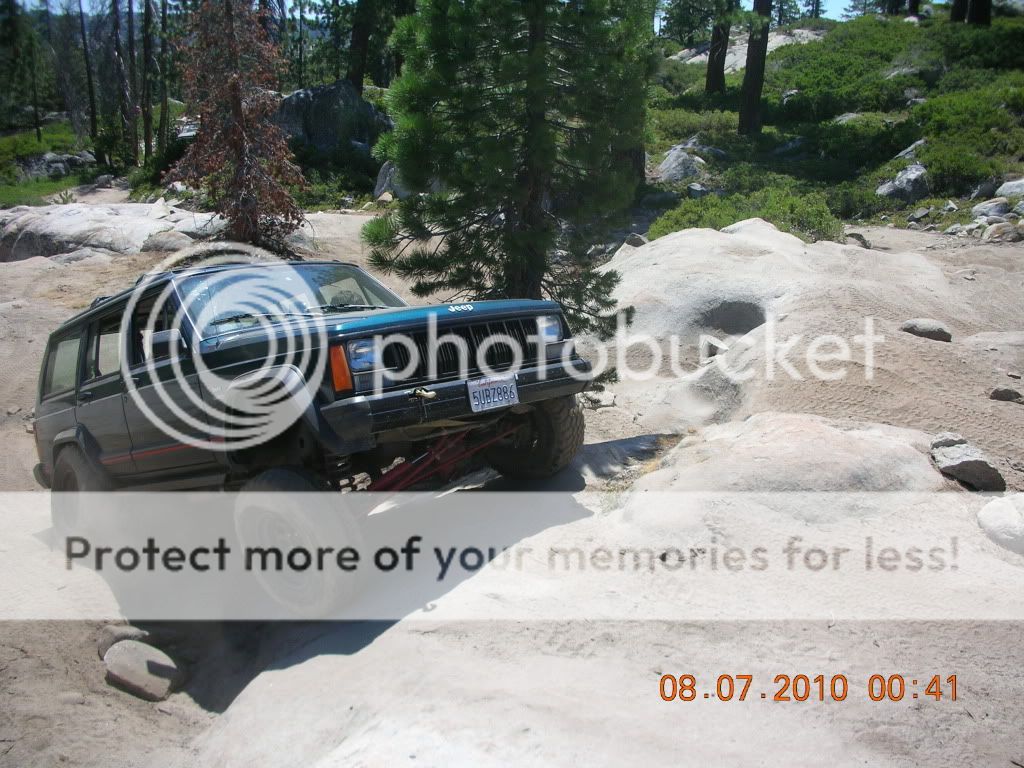

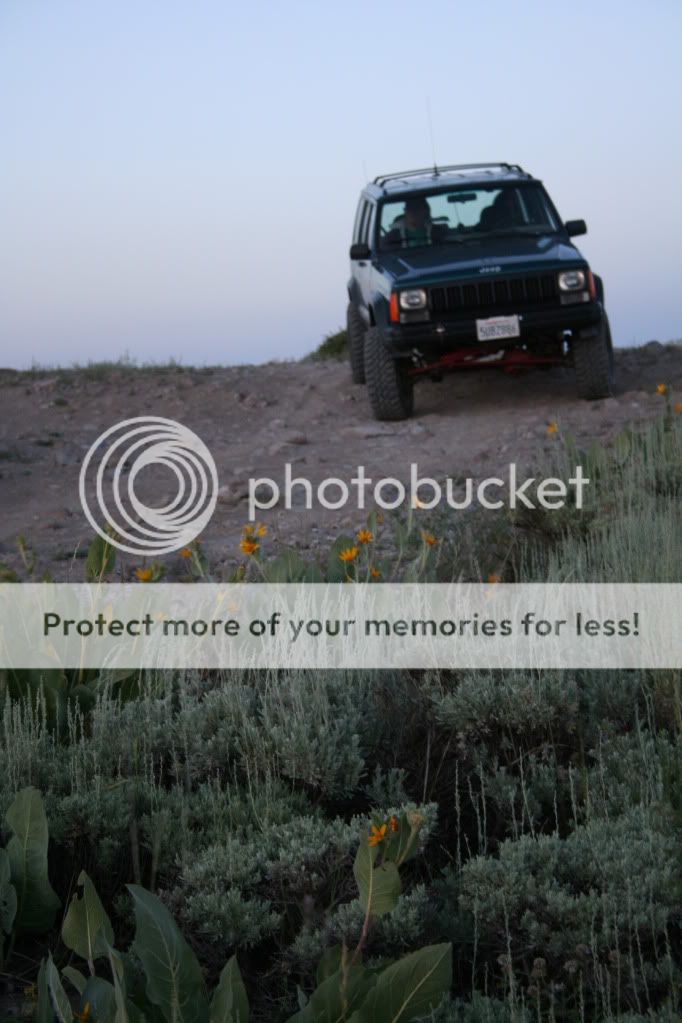

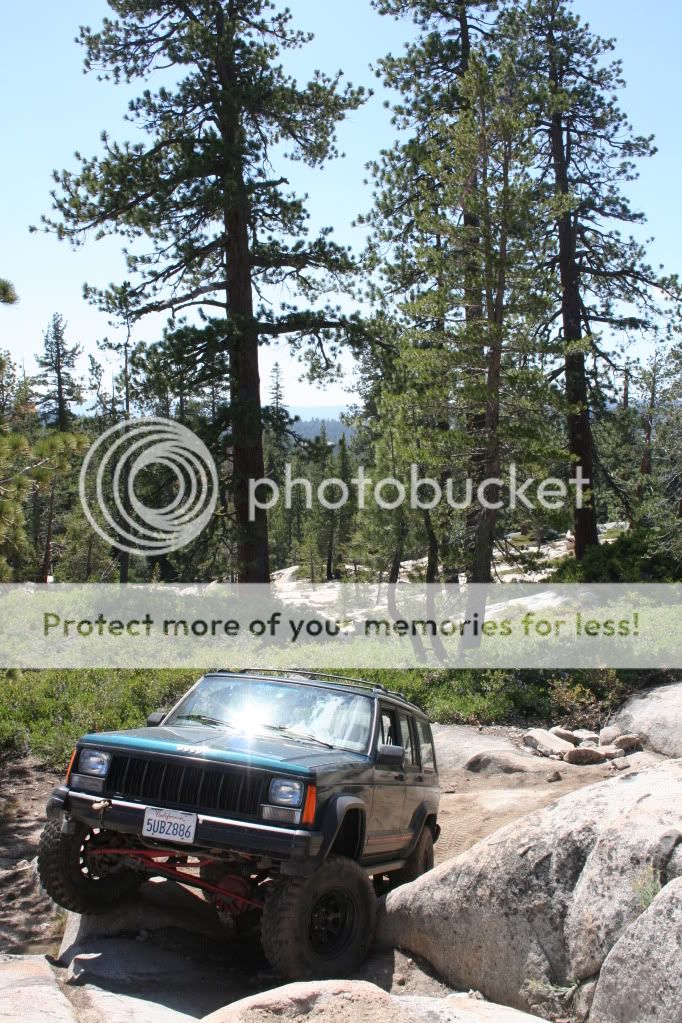

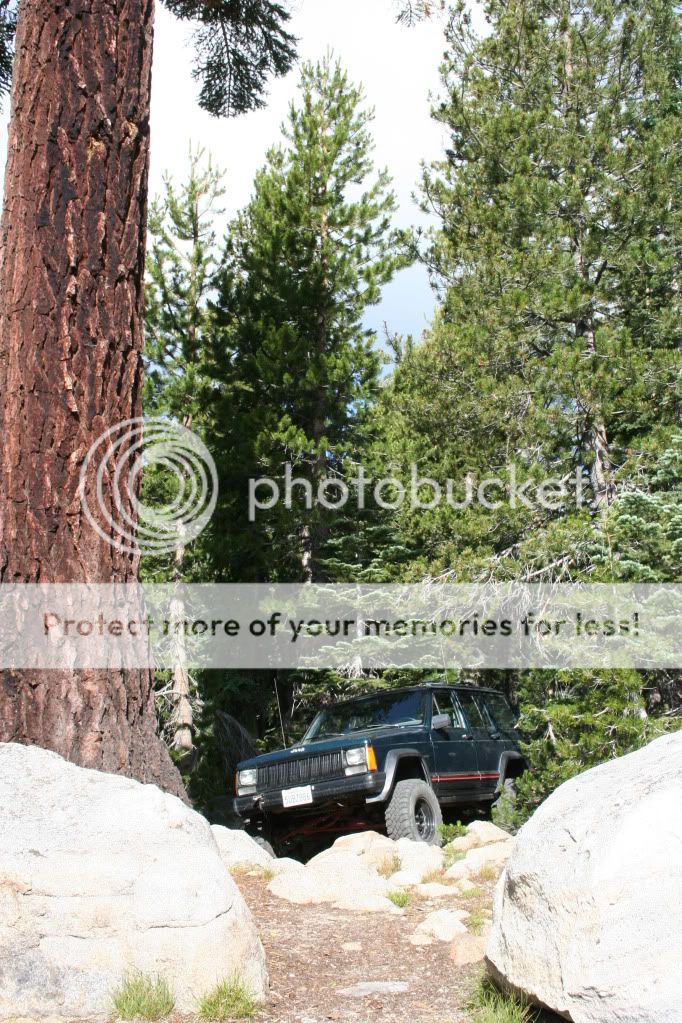

Heres some overall shots:

Ill have another shot or two coming in a few days.

All comments, questions, or concerns are more than welcome.