- Location

- Lafayette, CA

Introduction

Over the last four years I have been in the process of building a front high pinion Dana 44 for the front of my XJ. I thought some would like a write up on how I ended up narrowing a high pinion Ford 44 down to Waggy width and added all the bling.

Some might question why build a high pinion Dana 44 when you can build a Dana 60 for just a little bit more, and gain so much more strength.

For one, my Jeep is only on 35’’ MTRs. Second, I was able to keep a Dana 30 disconnect shaft with 260 joints alive locked for 3 years, so I figure a fully polished 44 should work for me. I will most likely never go above a 37’’ tire anytime soon, so a 60 is a bit big for my needs.

My Dad was also looking into building up his front Dana 30, and I decided it would be a good time to upgrade since he wanted most of the same parts I had in mine. Lets just say, he got one heck of a deal on all my old parts.

Other basic info on the Jeep: 1989 Jeep Cherokee, Renix I6, AW4, NP 231 with 4low, 2low and AA SYE, rear XJ 44 with a Detroit and 33 spline shafts, 35’’ Goodyear MTRs, and 6.5’’ of lift with TnT Y link radius arms.

At the end, the Dana 30 had: Alloy USA shafts, Detroit locker, BTF diff cover, and JCR OTK steering.

Dana 44

One of the hardest parts was finding the right axle. I had been reading countless threads about which axle to use, ranging from a 1971 to 1979 from F100s, F150s and Broncos. After a lot of correspondence with people who had built hp44s, and finally being shown Mr. N's Dana 44 Solid Front Axle page, I narrowed my search to a 1971 to 1976 F100 axle.

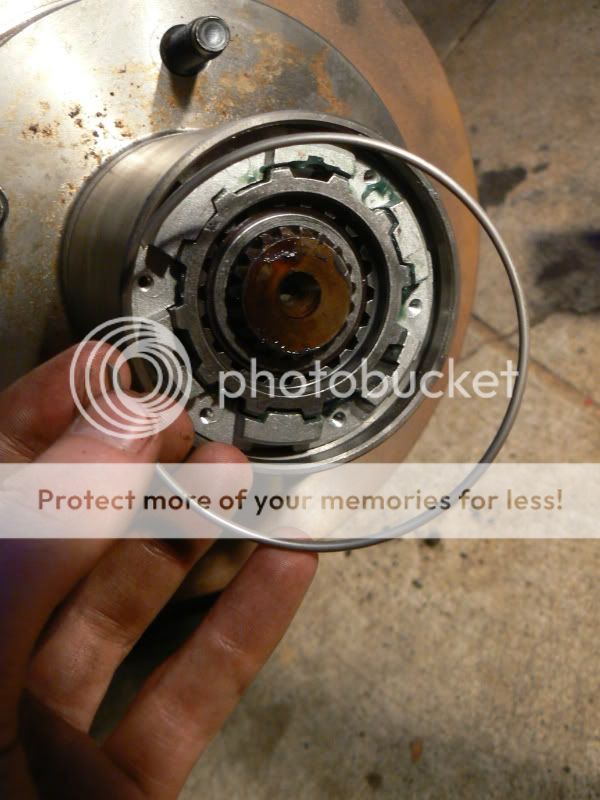

I finally found a late 1970’s Bronco axle on Craigslist and emailed the guy asking what exactly he had. I came to find that he had two 44s. One, which was a later ‘70s axle which was semi complete with disk brakes, and another which was an early ‘70s 44 that was bare and originally came with drum brakes. I took the second as it was cheaper and I had no use for the outers as I would be replacing them anyways. The guy also gave me a bunch of extra shafts, and a 10 bolt. None of which I wanted, but I figured I might be able to use the parts.

This is what I came home with:

I was thankful I passed on the more expensive axle when I came across Cruzin Illusion’s build , where he expressed his disappointment at buying a disked 44.

Fast forward a year and a half, and I finally started working on the axle.

Tech!!

Cutting wedges

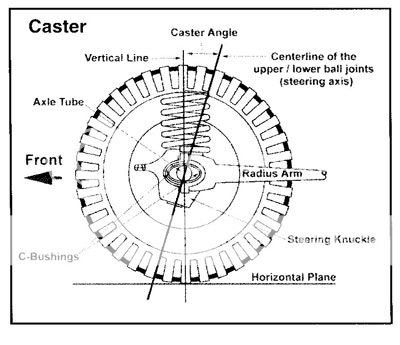

The main reason people want the pre ’78 axles is the wedges the factory radius arms mount to are welded onto the tube, rather than cast into the tubes like the ’78 and ’79 axles.

These pictures are borrowed from Mr. N, and shows the later cast wedges.

That cast portion cut in half, showing no axle tube:

This is my axle showing the welded on wedges:

To be honest, I was scared at taking this first step. I thought I might cut into the tubes, and render the axle useless. I finally manned up, and started cutting. I used a grinder with a cut off blade, and I cut before the weld. I then used a grinder to get the rest of the weld off.

Off:

All four wedges cut off as well as the steering stabilizer mount.

I then waited another six months to start doing the next step of this process as I had to go back to school.

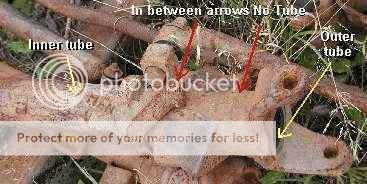

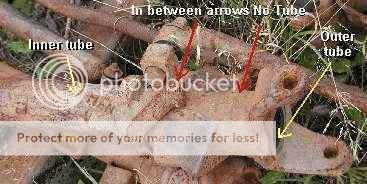

What the heck do I have?

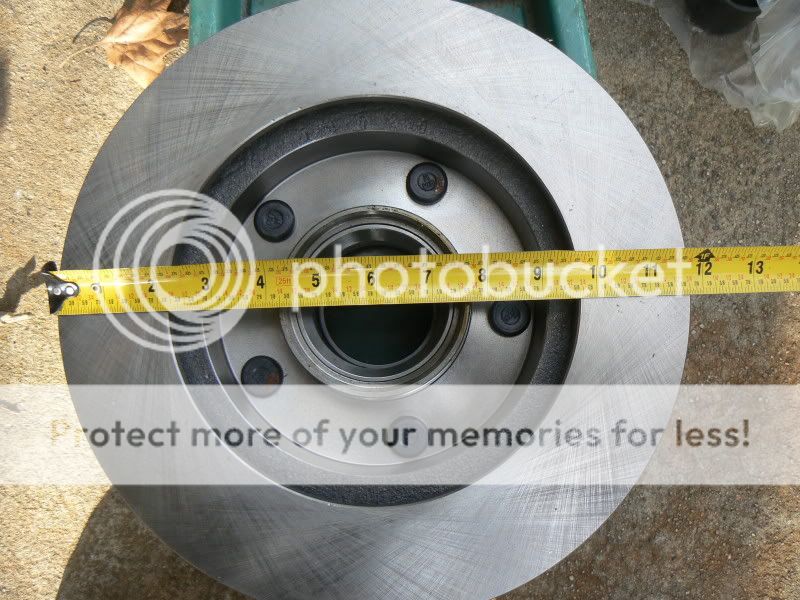

I knew I had an early 1970’s high pinion 44, but I had no idea what it was out of or what year it was, and I needed that information to find out how much I should narrow it by.

I asked about the Build of Materials that was stamped on the axle, and was able to find out my axle was from a 1773-1975 Ford F-100.

Shaft lengths:

Long side-33.906"

Short side- 18.906"

Over the last four years I have been in the process of building a front high pinion Dana 44 for the front of my XJ. I thought some would like a write up on how I ended up narrowing a high pinion Ford 44 down to Waggy width and added all the bling.

Some might question why build a high pinion Dana 44 when you can build a Dana 60 for just a little bit more, and gain so much more strength.

For one, my Jeep is only on 35’’ MTRs. Second, I was able to keep a Dana 30 disconnect shaft with 260 joints alive locked for 3 years, so I figure a fully polished 44 should work for me. I will most likely never go above a 37’’ tire anytime soon, so a 60 is a bit big for my needs.

My Dad was also looking into building up his front Dana 30, and I decided it would be a good time to upgrade since he wanted most of the same parts I had in mine. Lets just say, he got one heck of a deal on all my old parts.

Other basic info on the Jeep: 1989 Jeep Cherokee, Renix I6, AW4, NP 231 with 4low, 2low and AA SYE, rear XJ 44 with a Detroit and 33 spline shafts, 35’’ Goodyear MTRs, and 6.5’’ of lift with TnT Y link radius arms.

At the end, the Dana 30 had: Alloy USA shafts, Detroit locker, BTF diff cover, and JCR OTK steering.

Dana 44

One of the hardest parts was finding the right axle. I had been reading countless threads about which axle to use, ranging from a 1971 to 1979 from F100s, F150s and Broncos. After a lot of correspondence with people who had built hp44s, and finally being shown Mr. N's Dana 44 Solid Front Axle page, I narrowed my search to a 1971 to 1976 F100 axle.

I finally found a late 1970’s Bronco axle on Craigslist and emailed the guy asking what exactly he had. I came to find that he had two 44s. One, which was a later ‘70s axle which was semi complete with disk brakes, and another which was an early ‘70s 44 that was bare and originally came with drum brakes. I took the second as it was cheaper and I had no use for the outers as I would be replacing them anyways. The guy also gave me a bunch of extra shafts, and a 10 bolt. None of which I wanted, but I figured I might be able to use the parts.

This is what I came home with:

I was thankful I passed on the more expensive axle when I came across Cruzin Illusion’s build , where he expressed his disappointment at buying a disked 44.

Fast forward a year and a half, and I finally started working on the axle.

Tech!!

Cutting wedges

The main reason people want the pre ’78 axles is the wedges the factory radius arms mount to are welded onto the tube, rather than cast into the tubes like the ’78 and ’79 axles.

These pictures are borrowed from Mr. N, and shows the later cast wedges.

That cast portion cut in half, showing no axle tube:

This is my axle showing the welded on wedges:

To be honest, I was scared at taking this first step. I thought I might cut into the tubes, and render the axle useless. I finally manned up, and started cutting. I used a grinder with a cut off blade, and I cut before the weld. I then used a grinder to get the rest of the weld off.

Off:

All four wedges cut off as well as the steering stabilizer mount.

I then waited another six months to start doing the next step of this process as I had to go back to school.

What the heck do I have?

I knew I had an early 1970’s high pinion 44, but I had no idea what it was out of or what year it was, and I needed that information to find out how much I should narrow it by.

I asked about the Build of Materials that was stamped on the axle, and was able to find out my axle was from a 1773-1975 Ford F-100.

Shaft lengths:

Long side-33.906"

Short side- 18.906"

Raffle XJ, and figured I saw it done once, so I could do it easily the second time. Not quite the case.

Raffle XJ, and figured I saw it done once, so I could do it easily the second time. Not quite the case.