You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

beater!

- Thread starter ehall

- Start date

- Location

- Southern Maryland

Found more damage, gotta move the suspension rebuild up the list

- Location

- Southern Maryland

Tried to get a start on repairing damage yesterday but ran into two show-stopping problems right away. First I wanted to replace the short-arm lift with the StinkyFab / Synergy long-arm parts I had already bought, but when I started the work I found the driver side frame rail is crushed right where the StinkyFab long-arm mounts are supposed to slide on, so I will have to fix that damage before I can install the mounts.

Then I went to replace the broken leaf springs, and found the driver side forward bucket was pushed through the floorboard, and the inboard bolt hole was egged out from the angle, so have to replace or rebuild the leaf buckets as well.

At that point I got a buddy to help me weld the broken LCA bucket back to the body so that its somewhat safe to drive, and called it a day.

Good news I am closing on a house with an attached garage in a few days, should be able to spend more time working on stuff.

Decision point here: Option A is buy the Synergy replacement leaf buckets and some frame stiffeners, rebuild the floorpan, frame, and all the associated work (ex rockers). Option B is buy another XJ and do the work to it. I'm leaning towards option B at the moment. However I have some other projects going on (including a new house) so time and money will be tight for either. Out of the game for a little while either way.

Then I went to replace the broken leaf springs, and found the driver side forward bucket was pushed through the floorboard, and the inboard bolt hole was egged out from the angle, so have to replace or rebuild the leaf buckets as well.

At that point I got a buddy to help me weld the broken LCA bucket back to the body so that its somewhat safe to drive, and called it a day.

Good news I am closing on a house with an attached garage in a few days, should be able to spend more time working on stuff.

Decision point here: Option A is buy the Synergy replacement leaf buckets and some frame stiffeners, rebuild the floorpan, frame, and all the associated work (ex rockers). Option B is buy another XJ and do the work to it. I'm leaning towards option B at the moment. However I have some other projects going on (including a new house) so time and money will be tight for either. Out of the game for a little while either way.

Last edited:

Eric, assuming you may still make nacfest, you may want to chat with your old pal Richie. I have possession of one clean 01 with a bad motor and can get another 00 right away with same problem. One is maroon and one is white. Both are sport models with all the power goodies and clean chassis, with no other known problems. I could tow either one down to you after the fest, I simply have no room left here to bring the white one home. Either one would come with a clean title.

- Location

- NJ, U.S.A.

I was looking at the Synergy buckets last year, and I think they're out of production. Unless you've found that they're making them again?

Ironman Fab has some hangers. They may work for the stock hanger position. Haven’t really done a ton of research. My bolt holes are wallowed out too.

https://www.ironman4x4fab.com/product-page/xj-leaf-spring-mount-stretch-kit

Sent from my iPhone using Tapatalk

https://www.ironman4x4fab.com/product-page/xj-leaf-spring-mount-stretch-kit

Sent from my iPhone using Tapatalk

- Location

- NJ, U.S.A.

Ooh, didn't know about those. Have to remember those...

- Location

- Southern Maryland

Local guy trying to unload some assets, so I picked up a 98 Limited for a song. Amethyst Pearl exterior, tan interior. Suspension is rusty, but the body looks clean underneath (rockers are intact), just a couple of spots on the upper body. Starts and drives, AC works. ABS light is on but I need to delete anyway, steering leak, brake lines rusty, etc. Almost 200k on the clock. My plan is to move the suspension parts over to it eventually, but I need to address some basic issues first and get it through inspection.

Not done with the old beater yet. I am probably going to buy those Iron Man hangars and try to do the upgrades I already have on hand. Don't know when I can get to it, new house is killing me on time.

Not done with the old beater yet. I am probably going to buy those Iron Man hangars and try to do the upgrades I already have on hand. Don't know when I can get to it, new house is killing me on time.

- Location

- Southern Maryland

I got the amethyst XJ fixed and through inspection, now working as my new DD.

Now that I have reliable winter transportation available I'm starting on the undercarriage mods to the trail beater. Taking the week off work, hope to have everything done before next weekend.

Now that I have reliable winter transportation available I'm starting on the undercarriage mods to the trail beater. Taking the week off work, hope to have everything done before next weekend.

Last edited:

- Location

- Southern Maryland

Got a lot done on the upgrades, still a lot left to do. Winding back to the beginning and working through here:

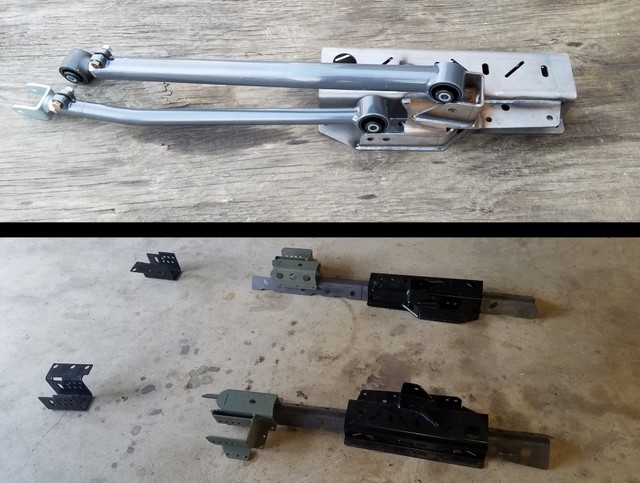

The parts I'm working with are the JCR 3/16" mid frame stiffeners, Stinky Fab long arm brackets, Synergy long arms with the dual-durometer ends, Iron Man 4x4 forward leaf hangars, and HD Off-Road no-lift shackle brackets.

I had to make some mods to get the SFR brackets working with the other parts. For one, the ears had to be spread to fit the Synergy joints. And I had to notch the TNT HD crossmember to fit the LCA mounts. A local guy that does metal work on the side did them both.

I was originally planning to install all the brackets directly to the frame rail and cut the stiffeners to fit, but the SFR brackets are engineered so that they can fit over a frame stiffener as well. However there are some clearance issues that have to be worked out. In particular I found that I had to remove most of the pinch seam, so I decided to just cut it flush and tack weld the halves back together. I cut all the way up through the LCA on the same line, then came back and tacked them back together. More tacks than original so should be okay.

Also chopped the stock UCA bracket to make room for the upper arm

With the frame rail clearanced we cleaned the undercoating off with a 5" knotted wire brush (fast), then sanded and cleaned the areas for welding.

The rear end of the stiffener goes all the way back to the stock forward leaf hanger, but the Iron Man 4x4 hanger comes up forwards a few inches, so I chopped the end off the stiffener before welding.

After welding it down, packed the seams with sealer and covered with primer, then marked and sanded the areas that needed welding for the SFR brackets

The Synergy arms are designed to install with the adjustment clamp at the top rear of the arm, however the clamp interferes with the SFR bracket, so I had to swap the arms left-right to and turn them upside-down (had to swap to keep the curve for the tire inwards).

Another problem: the SFR brackets are designed so that the hard lines on the driver side can run between the bracket and the frame rail, but with the stiffener pulling the bracket over the gap is pretty tight. In particular my 91 has the quick connect for the high-pressure fuel line in that gap, and the bracket would not install over it.

The first attempt to fix it involved cutting a 1.75" hole in the side of the frame rail that the fitting could recess into, but I did not like the idea of having the quick connect trapped in there with the welded bracket. So I changed up and routed the lines over the bracket instead. It gets a little busy there with the UCA and the driveshaft but everything seems to clear alright. I am probably going to cut some rubber hose and splice over the hard lines to provide some padding but it seems alright for now.

Final install with the JCR stiffeners welded in, and the SFR brackets welded to the stiffeners. Uppers are set for 29.5" and the lowers are set for 31.75", almost twice the length of the short arms I was running before. The lowers curving down presents a couple of minor issues, but also presents some opportunity. For one thing they are likely to drag, but they will also act as belly skids for some things, which is good. They also gain a lot of room for travel at both ends (up-travel at the frame and down-travel at the axle).

After it was all bolted up I did a little driving around in the yard and cul de sac, everything feels good. Have not tested travel or anything yet, but I did put one tire in a ditch and it stayed planted the whole time.

4-day weekend coming up for Thanksgiving, so I will try to get the rear brackets installed with the RE 4.5 leaf packs. After that I will come back to the front axle and install a set of MetalCloak coils and do some other work. Then I have to fix the doors and heated seats so I can go winter wheeling.

The parts I'm working with are the JCR 3/16" mid frame stiffeners, Stinky Fab long arm brackets, Synergy long arms with the dual-durometer ends, Iron Man 4x4 forward leaf hangars, and HD Off-Road no-lift shackle brackets.

I had to make some mods to get the SFR brackets working with the other parts. For one, the ears had to be spread to fit the Synergy joints. And I had to notch the TNT HD crossmember to fit the LCA mounts. A local guy that does metal work on the side did them both.

I was originally planning to install all the brackets directly to the frame rail and cut the stiffeners to fit, but the SFR brackets are engineered so that they can fit over a frame stiffener as well. However there are some clearance issues that have to be worked out. In particular I found that I had to remove most of the pinch seam, so I decided to just cut it flush and tack weld the halves back together. I cut all the way up through the LCA on the same line, then came back and tacked them back together. More tacks than original so should be okay.

Also chopped the stock UCA bracket to make room for the upper arm

With the frame rail clearanced we cleaned the undercoating off with a 5" knotted wire brush (fast), then sanded and cleaned the areas for welding.

The rear end of the stiffener goes all the way back to the stock forward leaf hanger, but the Iron Man 4x4 hanger comes up forwards a few inches, so I chopped the end off the stiffener before welding.

After welding it down, packed the seams with sealer and covered with primer, then marked and sanded the areas that needed welding for the SFR brackets

The Synergy arms are designed to install with the adjustment clamp at the top rear of the arm, however the clamp interferes with the SFR bracket, so I had to swap the arms left-right to and turn them upside-down (had to swap to keep the curve for the tire inwards).

Another problem: the SFR brackets are designed so that the hard lines on the driver side can run between the bracket and the frame rail, but with the stiffener pulling the bracket over the gap is pretty tight. In particular my 91 has the quick connect for the high-pressure fuel line in that gap, and the bracket would not install over it.

The first attempt to fix it involved cutting a 1.75" hole in the side of the frame rail that the fitting could recess into, but I did not like the idea of having the quick connect trapped in there with the welded bracket. So I changed up and routed the lines over the bracket instead. It gets a little busy there with the UCA and the driveshaft but everything seems to clear alright. I am probably going to cut some rubber hose and splice over the hard lines to provide some padding but it seems alright for now.

Final install with the JCR stiffeners welded in, and the SFR brackets welded to the stiffeners. Uppers are set for 29.5" and the lowers are set for 31.75", almost twice the length of the short arms I was running before. The lowers curving down presents a couple of minor issues, but also presents some opportunity. For one thing they are likely to drag, but they will also act as belly skids for some things, which is good. They also gain a lot of room for travel at both ends (up-travel at the frame and down-travel at the axle).

After it was all bolted up I did a little driving around in the yard and cul de sac, everything feels good. Have not tested travel or anything yet, but I did put one tire in a ditch and it stayed planted the whole time.

4-day weekend coming up for Thanksgiving, so I will try to get the rear brackets installed with the RE 4.5 leaf packs. After that I will come back to the front axle and install a set of MetalCloak coils and do some other work. Then I have to fix the doors and heated seats so I can go winter wheeling.

Last edited:

OverlandZJ

NAXJA Member # 101

- Location

- Bristol,PA

Nice addition to the fleet! Gave up on the Caddy after all these years?

- Location

- Southern Maryland

Hi John! No I still have the Cadillac, just put it under cover for the winter.

Last edited:

- Location

- Southern Maryland

Got the rear mostly done. Started by cutting off the front and rear leaf buckets, using a Blair roto bit to drill out the spot welds, then my trusty old angle grinder to cut and clean the rest. The floorboard over the front left hangar had rusted through and the hanger was punching up through the floorboard a lot, enough for the bolt hole in the stock hanger to oval out.

Since the body is already fkd beyond repair I decided to just patch over the damage. Started with some cut sheet metal, then filled the wound with bathtub caulk, sandwiched between another piece inside. Just need it to last a couple of years

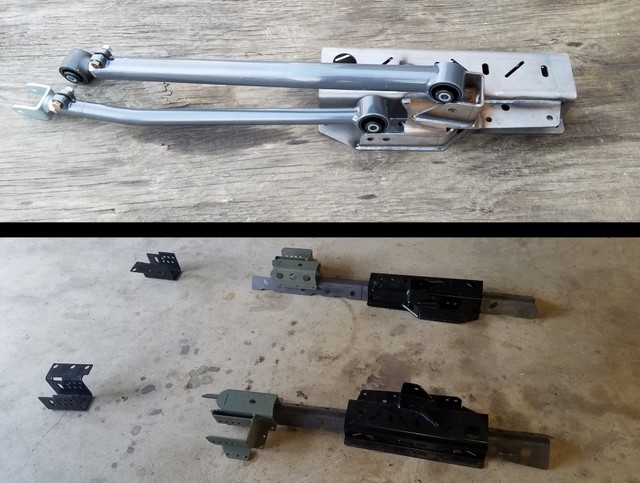

I had originally planned to install the Iron Man hangars flush with the frame stiffeners but after some test fitting I decided to keep it back a little and add another hole up front. Friend of mine with a nice drill press helped me add another hole 7/8" from the rear, which will let me run leafs with a front half that is either 2.75" longer (Ford) or 3" longer (Chevy, Comanche). And I still have the trailing hole that will let me shift a stock leaf backwards 1" for longer wheel base. Welded in place no problems

For the rear I went with the HD Off-Road no-lift shackle relocators. Pretty simple installation. I should be able to run a leaf with a slightly longer rear and not hit the bumper, but nothing extremely long (probably no Comanche leaf)

new RE 4.5 leaf packs and Clayton adjustable shackle at max length. Right now the shackle is in the SRB at the rear-most hole on the lower row, and the leaf is about 1" taller than expected. I will move it forward one hole for steeper angle to cut some lift and increase downtravel.

Need to do some cleanup work in the rear, torque stuff down, then turn the Jeep back around to swap the front coils and do some work on the front axle

Since the body is already fkd beyond repair I decided to just patch over the damage. Started with some cut sheet metal, then filled the wound with bathtub caulk, sandwiched between another piece inside. Just need it to last a couple of years

I had originally planned to install the Iron Man hangars flush with the frame stiffeners but after some test fitting I decided to keep it back a little and add another hole up front. Friend of mine with a nice drill press helped me add another hole 7/8" from the rear, which will let me run leafs with a front half that is either 2.75" longer (Ford) or 3" longer (Chevy, Comanche). And I still have the trailing hole that will let me shift a stock leaf backwards 1" for longer wheel base. Welded in place no problems

For the rear I went with the HD Off-Road no-lift shackle relocators. Pretty simple installation. I should be able to run a leaf with a slightly longer rear and not hit the bumper, but nothing extremely long (probably no Comanche leaf)

new RE 4.5 leaf packs and Clayton adjustable shackle at max length. Right now the shackle is in the SRB at the rear-most hole on the lower row, and the leaf is about 1" taller than expected. I will move it forward one hole for steeper angle to cut some lift and increase downtravel.

Need to do some cleanup work in the rear, torque stuff down, then turn the Jeep back around to swap the front coils and do some work on the front axle

StinkyArmpits

NAXJA Forum User

- Location

- Freeland,Pa

How do you plan to keep the "frame rails" from rusting behind your new bracketry?

- Location

- Southern Maryland

No plan for it

- Location

- NJ, U.S.A.

Here's an "off the wall" question:

There are now "structural adhesives" that are supposedly as as strong as welding (if not stronger), some manufacturers are now even using that instead of welding. Would a healthy coating of 3M structural adhesive on the "inside" (contacting the frame/body) surfaces be equivalent to actual welding for installing these?

There are now "structural adhesives" that are supposedly as as strong as welding (if not stronger), some manufacturers are now even using that instead of welding. Would a healthy coating of 3M structural adhesive on the "inside" (contacting the frame/body) surfaces be equivalent to actual welding for installing these?

StinkyArmpits

NAXJA Forum User

- Location

- Freeland,Pa

You mean you want to glue spring hangers to your jeep? You do it first and let me know how it works, lol.

- Location

- Southern Maryland

I'm sure it would work. Except you couldn't weld to the metal since you'd burn off the adhesive.

I've seen hilti epoxy fasten steel studs into a dusty hole drilled into a 100 year old brick wall that held up to 300# of force within 15 minutes, so don't underestimate the power of that technology.

That said, given flexural stress and weather conditions over time, I'm not going to be the guy who'd bet his butt on it. Welding is still the best answer to this.

That said, given flexural stress and weather conditions over time, I'm not going to be the guy who'd bet his butt on it. Welding is still the best answer to this.

- Location

- Southern Maryland

Installed the MetalCloak coils. Removed the adjustable ring of the ACOS and run just the top spacer and isolator for 1-3/8 spacing, rear is still about 1/4-to-1/2 higher, hopefully it all settles out right.

Replaced the swaybar brackets with Clayton extended tabs, clears the steering fine now, need to go over-the-knuckle tie-rod on the driver side but forgot to order the insert and don't have the drill / reamer anyway.

Replaced the Prothane bumps with new ones. Also built new caps for them, using longer pipe nipples. Used seam sealer to try to keep the caps from flying off like last time.

Need to modify my rocker rails then on the road to Rausch

Similar threads

- Replies

- 7

- Views

- 224

- Replies

- 0

- Views

- 79

- Replies

- 0

- Views

- 965