Vanimal

NAXJA Forum User

- Location

- escondido, ca

ill be in truckhaven tomorrow!If you didn't go today I could probably roll with you tomorrow afternoon if you want.

Matt

ill be in truckhaven tomorrow!If you didn't go today I could probably roll with you tomorrow afternoon if you want.

Matt

i remember my first drag raceWaiting on dan out at LW now, anyone else wanna cruise by?

mine was actually faster off the line with the 3.07's. it runs out of gear too soon with the 4.56's. also, my ghetto shift knob came off in my hand between 1-2.No problems on the way home. I thought you would have pulled a little harder though with 4.56/31 vs. 4.10/33

no pics flexed out yet, but it does flex pretty good on the back.Lookin real nice Dan! any flex pics? Curious to see the rear in action.

Now ya gotta do something about that stock steering next!

Looking very good there Dan, nice work. Don't you love it when a plan comes together.

I find that you have to be patient and stitch weld when welding upside down.thanks John. i struggle with overhead/upside down welding, but im starting to figure it out. im pretty confident they'll stick at this point at least.

yea, figured that one out, getting a little better at it.faster wire speed helps also.

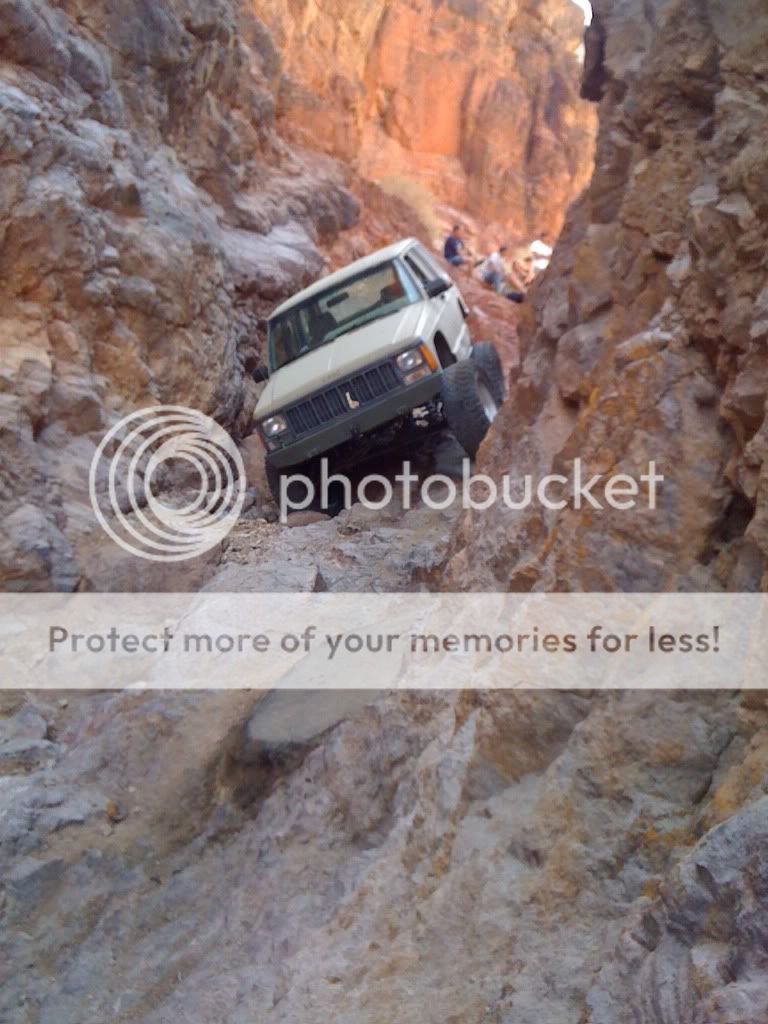

damn, i thought there were 10 posts per page. Sorry Burt Reynolds, you have to stay. well here's some pics.

hope i can learn to weld before the end of this project. getting a little better as it progresses.

LOL it's cranked man! it's a little 90a 115v lincoln. i just need a bigger welderthese welds are not bad at all. but if you can, turn up the heat and speed a little more. you want to be able to see just a little more of a burn in on the edge of the bead. remember you are trying to MELT both pieces together, not just glue them sort of speak.

so I do need a doubler or an atlas, it's geared just a little too high to be able to creep up stuff without having to work the clutch a little. however, i do not want to go much lower than what i have (4.56's) since i want it to be streetable.