northwestxj

NAXJA Member #1283

- Location

- washington

I've wanted to build a roll cage in my XJ for quite some time now. Hybrid cages that are popular in my area (PNW) have always appealed to me. They offer good protection (both to the passengers and Jeep) and are still visually appealing. After a few recent wheeling trips I knew it was time to start on one. Here's some of the beginning stuff.

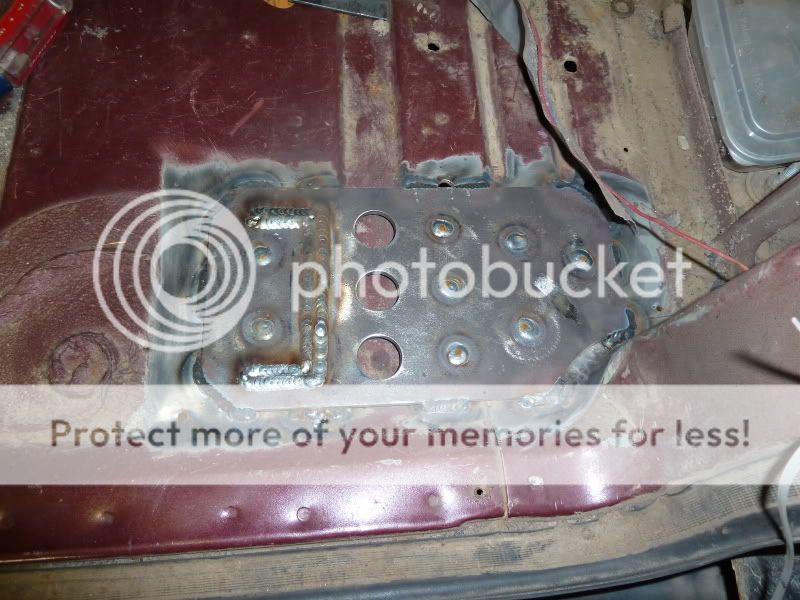

I started by plating my rear frame rails because I wanted to run my rear shocks through the floor and plating them would make a solid spot to weld to. I plated the outside first.

Then I plated a section of the inside as well. I came up with an idea to run the top section of the inside plate through the floor board (through a slit in the floor) so I could weld that frame plate to my "D" pillar plate. This way, the frame is tied into the "D" pillar plate instead of the plate simply being welded to the sheet metal floor. This will increase strength and also rigidity of the the whole back end of the Jeep due to the cage being tied directly into the frame. Here's the cut out plates:

Drivers side (big notch is for the cutout for the gas tank filler hoses)

Passenger side

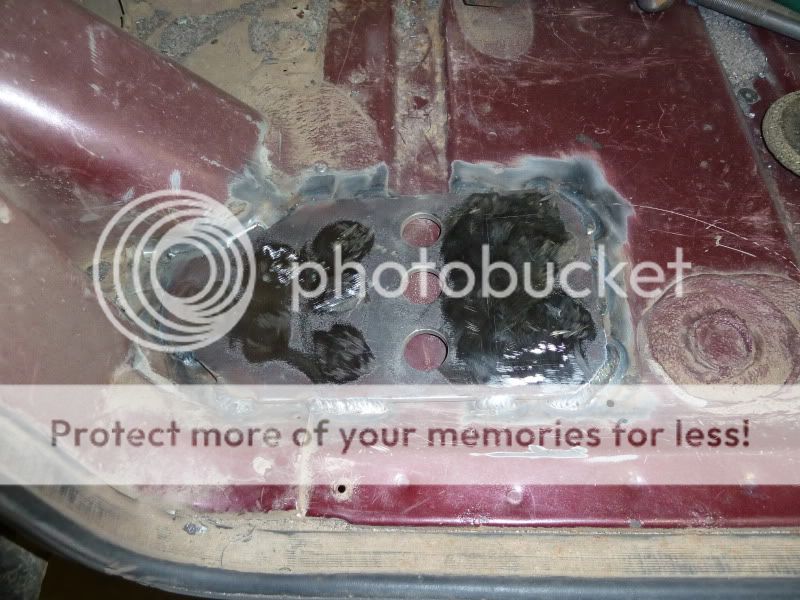

Then I cut the slit in the floor and prepped for the "D" pillar floor plate

Here is the inside plates, along with a couple gussets for each side welded on: (The nuts that are welded on are for my rear bumper tie in's as the bolts now run through the frame, that is sleeved, and into those nuts)

Drivers

Passenger

Here is the the top of them poking through the floor

Next I made some "D" pillar plates with the slit for the the inside frame plate and gussets to come through. I beveled around the slit for better welding

I started by plating my rear frame rails because I wanted to run my rear shocks through the floor and plating them would make a solid spot to weld to. I plated the outside first.

Then I plated a section of the inside as well. I came up with an idea to run the top section of the inside plate through the floor board (through a slit in the floor) so I could weld that frame plate to my "D" pillar plate. This way, the frame is tied into the "D" pillar plate instead of the plate simply being welded to the sheet metal floor. This will increase strength and also rigidity of the the whole back end of the Jeep due to the cage being tied directly into the frame. Here's the cut out plates:

Drivers side (big notch is for the cutout for the gas tank filler hoses)

Passenger side

Then I cut the slit in the floor and prepped for the "D" pillar floor plate

Here is the inside plates, along with a couple gussets for each side welded on: (The nuts that are welded on are for my rear bumper tie in's as the bolts now run through the frame, that is sleeved, and into those nuts)

Drivers

Passenger

Here is the the top of them poking through the floor

Next I made some "D" pillar plates with the slit for the the inside frame plate and gussets to come through. I beveled around the slit for better welding

triangulating their cage?

triangulating their cage?