I got some more paint on the axle and did a little more work on the exterior. One thing I've long wanted is to drill and tap the coil pads so that I can bolt hockey pucks in place, and I got that done with some 8mm button head screws that I had laying around.

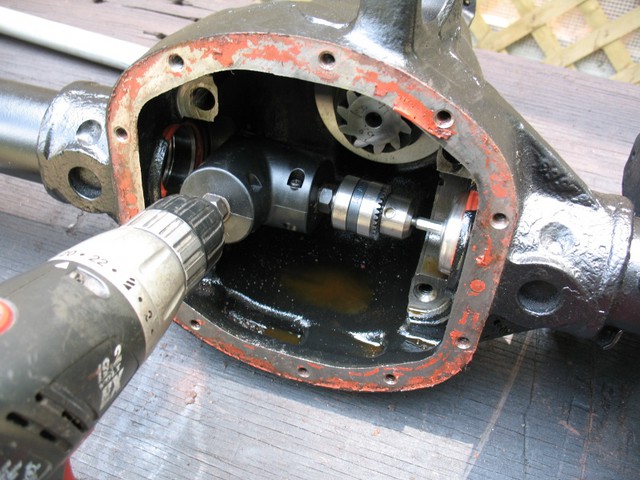

Today I got inside the axle. The differential itself looks pretty good, and the gears turn quiet with no clacking or anything. The only odd thing is that the axle looks like its off-centered a bit--the bearing on the left side of the pic has more exposed surface area, but the axle shaft on the right side has deeper insertion.

I didn't see any shims anywhere. I didn't remove the bearings so I assume they are behind those. Another thing I noticed was that there was some funk on the left (short) side of the differential but everything still looked alright. Everything hosed down with brake cleaner alright, and there weren't any bad noises

The right (long) side of the axle was pristine, but the left (short) side had a lot of corrosion build up

The corrosion was into the area where the seal sits, and had managed to work its way under the seal and also into the seal opening, so I had to clean this area before I could install the new seals. What I finally settled on was using a 90-degree attachment on the handheld drill with a wire brush. This worked really well and got the seal surface really clean. I wish I was able to run the wire brush all the way down the shaft but unfortunately I don't have an extender that will work, so I had to settle for rags and brake cleaner on the rest of it.

For the new seals, I had ordered a couple from Morris 4x4, which were like $3 each for Crown. One of them was damaged so I had to fish around locally, and eventually found some National 710068 axle shaft seals at Advance. A nearby Autozone had Timken 710068 seals too. These are all basically the same seal, like this Timken, with a curved lip to help guide the shaft into the differential and protect the seal rubber.

Some PVC conduit that was laying around worked as a rod, and a deep-well 36mm hub nut socket worked as an anvil. The conduit fit through the seal so I was able to use the same tool for both sides.

Everything went back together alright. I won't know until the differ cover is painted and dry if the installation was successful but at least I know what to do now.

I have decided to leave the current ball joints installed for now since they seem to be nice and tight (good preload) with no wobble. I have a pinion seal but haven't decided what to do with it--from what I have read they are easy to swap on the HP30 so I will do some more research and will probably swap it.

Other than that I am waiting for UCA bushings to show up and then I can swap the axle.

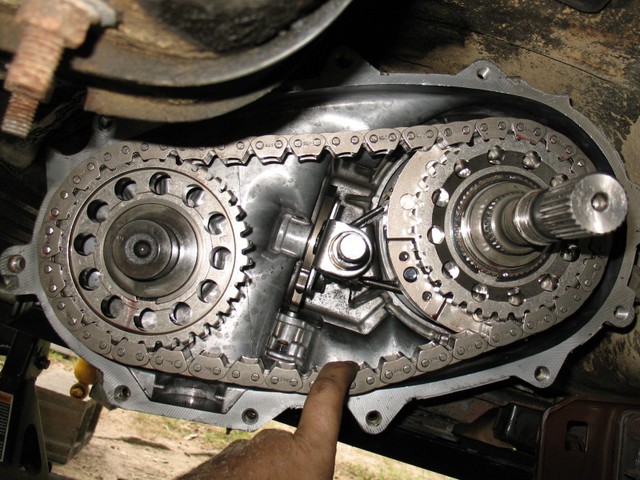

My transfer case noise seems to be the chain dragging. I have ordered a new Cloyes chain from rockauto and will install that at the same time as the axle swap probably.