Gravesdiggerxj

NAXJA Forum User

- Location

- Salt Lake City, Utah

^ He just wheels it now. Somehow he doesn't have the itch to keep building until it isn't street legal like the rest of us... Lol

VERY nice build man!

I love the front bumper design as well. At first, I was looking to a beefy, heavy steel setup, but the prerunner style is definitely growing on me. I didn't notice, but what's your front recovery?

I have two horizontally mounted tow hooks that mount up high under the main tube.

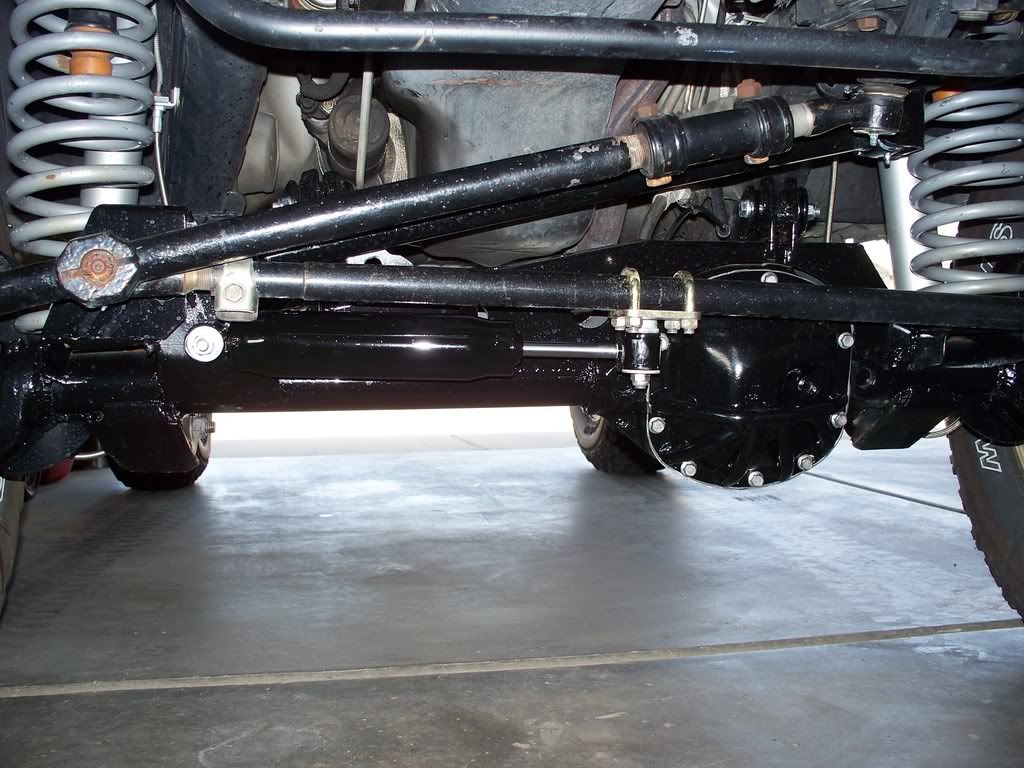

How do you like the T&T truss setup? Yes, it's a great pre-fabbed setup, arguably not as strong as a below housing truss, but a decent compromise.

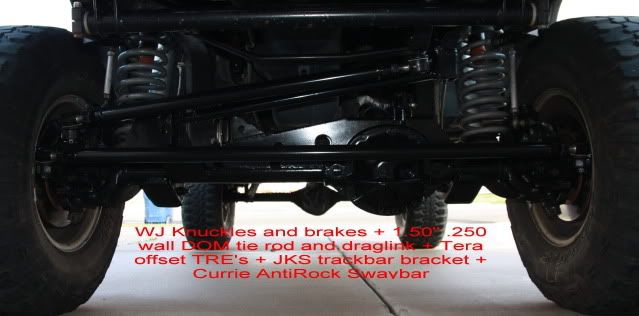

That looks like a JKS track bar mount also, true? Yes

I was thinking of fabbing a truss for my D30, but it looks like the T&T is a proven design, just gotta swallow the price. Time is money.......

Definitely enjoyed reading through your build thread, can't wait for another update!

EDIT:

One more thing I wanted to ask, how did you bend the tubing for the front bumper? Do you have a bender or did you take measurements and had a local shop do it?

I have a couple of buddys with benders. I have the drawings to build my own, just haven't got around to it yet.

Here's the front axle installed. I swapped out the poly bushing on the axle end of the trackbar for a heim, as there seemed to be too much play in it. Solved the problem. Everything works well together.

With 3 days left before Fall Fling, I started my front bumper. I planned on fabbing it to accept a winch that ideally would be recessed below the bumper and recessed into the front crossmember, which I will rework/strengthen. Time didn't allow for this, so I wound up with this.

Main tube is 1.75" DOM, hoop is 1.50" DOM and the side braces are 1" EW. I already had the 1.5 hoop from another bumper project and decided to use it, even though it was smaller than the main. Turned out OK.

Lower braces installed

I was on a dead run on this and didn't get as many shots as I wanted....I finished de-slagging the welds and quickly threw on 2 coats of Krylon on Thursday afternoon. I finished packing the Jeep while the paint dried and bolted in on before we hit the road to Moab so I never even took time to snap any installed shots, so this one will have to do.

Since I didn't get my Viair compressor installed, my ARB's were open for this run. Hells Gate was unusually slippery from a morning storm and sand tracked up from below, so I wound up taking a tug after sliding off the wallI, which allowed me to test the bumper brace as a tow point......yah, I meant to do that :laugh3:

The rig worked well, but as with any newly built rig, needs some fine tuning. I still need to install bump inserts in the coils, add a center strap to tune the droop because with 12.5" travel shocks, there is articulation o' plenty. Gotta get the ARB's plumbed and then work on sliders and rear bumper armor.........you know, a rig is never really "done".

Stay tuned................

Here's the front axle installed. I swapped out the poly bushing on the axle end of the trackbar for a heim, as there seemed to be too much play in it. Solved the problem. Everything works well together.

...

Hey what brand of trackbar and trackbar frame mount did you install here? Where did you get the heim joint to swap in? Thanks!

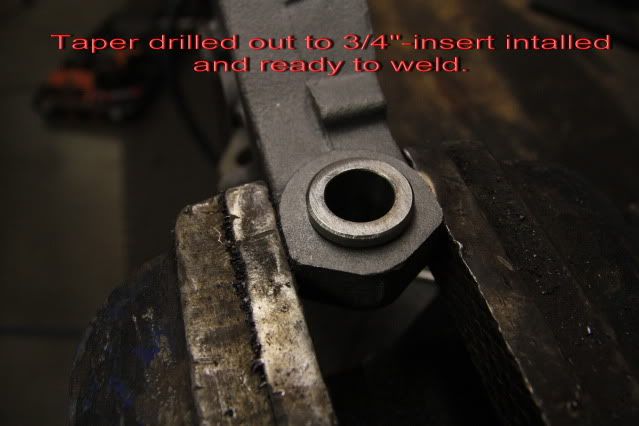

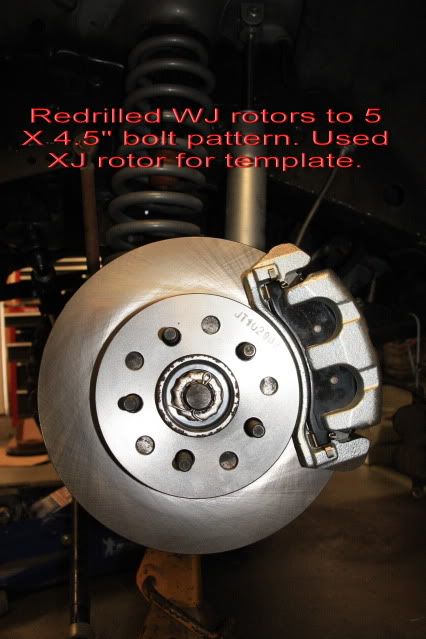

Did you do anything special to weld the spacers to the knuckles?

No, I had them soda blasted prior to welding so they were nice and clean.

I'm not an expert but I thought the knuckles are just cast steel. Not cast iron.

I was watching "Trucks" when they did this on a Grand Cherokee. Looks like they pre-heated and used a mig welder. Did you mig or stick it? Did you use any different rod or wire? Did you weld all the way around?

WJ knuckles are not cast steel, but nodular iron.

I bolted the unit bearings to the WJ knuckle with the JKS spacer in place and then tacked the JKS spacer to the WJ knuckle in several spots, using my Miller 175 and .035 wire. I then removed the unit bearing assembly and welded the spacers on solid using a manual pulsed method.

No mumbo-jumbo voodoo, pre/post heat concerns here......however I did throw the knuckles in 5gal buckets of dry sand and let them cool down slowly, just for fun.

Jeff, I want to be like you when I grow up.

Since I'm building another XJ, on 33's, for a driver it's nice to look back over your build and get some ideas. Maybe I'll bring it to Moab one of these times and we can play follow the leader.

and had to know what you are running. Love it man!

and had to know what you are running. Love it man!What size lift and tires are you running? I am doing a similar setup with my 2000, Rubicon Rims, 3.5" RE leaf pack (as you may know, got about 5" lift from them) 3" front springs with ACOS... Looking to keep it super clean and not fender trim like yours, saw it on the front page ofand had to know what you are running. Love it man!

Running the pinion -1* at static allows the pinion to operate at the proper angle when under power.