- Location

- In a strange land

In an effort to solve an intermittent death wobble (70+ mph, irregular freeway surfaces) I decided to start with the evidently worn track bar bushings . My trackbar is an aftermarket item, identified by good folks here on  as a Rubicon Express, RE1600 track bar. Google searches suggested that the Moog K3176 bushings were an option. Rubicon Express offers a replacement bushing kit as P/N RE1685. Additionally I was curious to see if I could make the Kevin’s Offroad KOR-9906-HW (9/16” track bar bolt kit) and KOR-1179-KIT (Extra hard bushing kit) work with the RE-1600 track bar. So I ordered all three kits.

as a Rubicon Express, RE1600 track bar. Google searches suggested that the Moog K3176 bushings were an option. Rubicon Express offers a replacement bushing kit as P/N RE1685. Additionally I was curious to see if I could make the Kevin’s Offroad KOR-9906-HW (9/16” track bar bolt kit) and KOR-1179-KIT (Extra hard bushing kit) work with the RE-1600 track bar. So I ordered all three kits.

I swear I took a picture of all three kits together, but doggoned if I can’t find it. It is probably mixed in with pictures of The Varmints somewhere and will show up when I am trying to put together a family calendar next December.

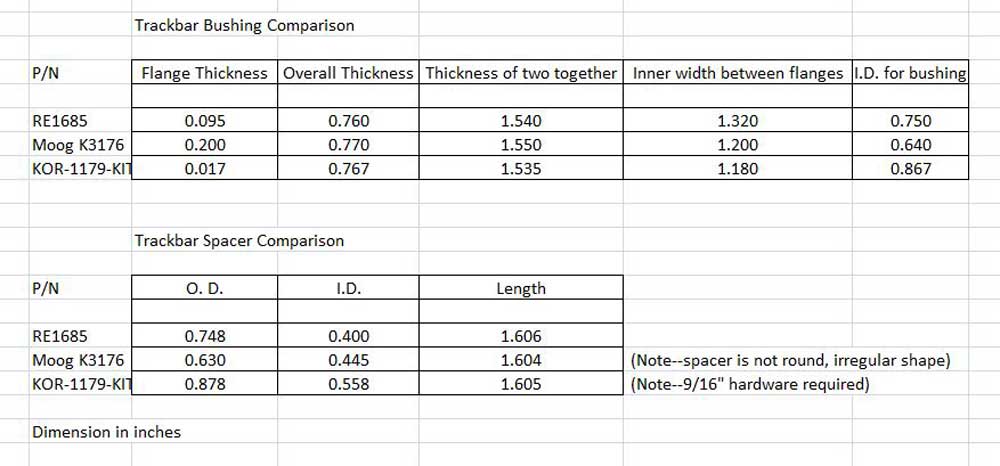

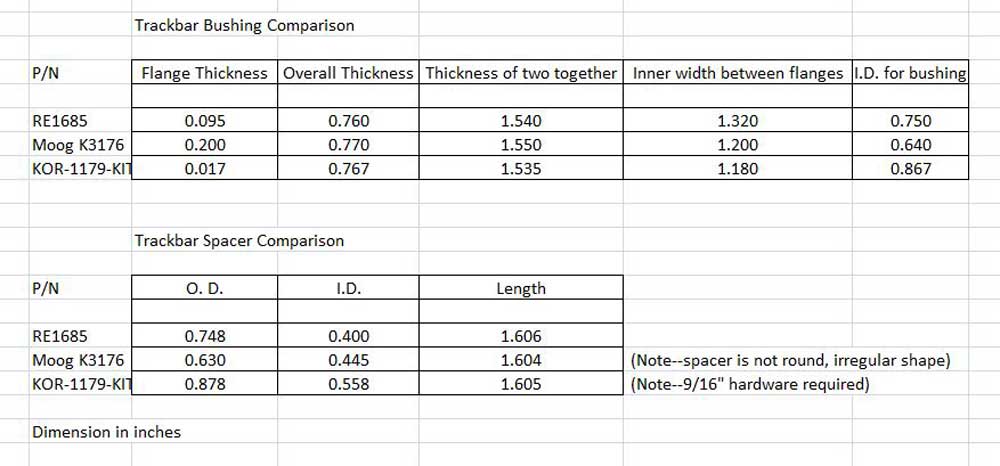

I do at least have measurements of all three kits. I will post those at the end.

The Moog K3176 parts strike me as junk. The bushings are very soft and the spacer is a piece of rolled sheet metal that is not even welded at the seam, nor is it even round. It might be a reasonable option if someone needed to be able to find a part while travelling, just for the sake of getting back home, but I would not want to run it for long. Additionally, I think installing it would be a PITA. The flanges are too thick for proper fitment with the RE1600.

The Rubicon Express RE1685 would be the safest way to go, provided the bolt holes in the bracket on your axles are not wallowed out. Only problem is, after 20-30 years that isn’t a safe bet.

Bumping up to the 9/16” bolt was my primary reason for wanting to try to run the Kevin’s Offroad parts, but I knew I was going to have to deal with the thicker flanges. Polyurethane can be machined though. Here is what I did to upgrade my hardware:

That powdery rust is the evidence that things are moving. This is why I want to move up from the factory hardware. That is from movement between the bolt and the hole in the bracket:

Here is the width of the RE1600 track bar: 1 7/16”. This is why the Kevin’s Offroad parts are not a direct drop-in. 1 3/16” is what those parts are designed for.

The difference between the 1 3/16” and the 1 7/16” is made up in the flange thickness. The RE1600 uses a flange that is less than 1/8” thick. The easy way to get to that thickness would be to chuck up the bushing and simply machine down the outside faces. The downside of this approach is that it would result in a larger gap inside the track bar. Better to mount the bushings on an arbor and then turn down the inside face of the flange. This way the overall thickness of the bushing remains unchanged and the gap in the middle is kept to a minimum.

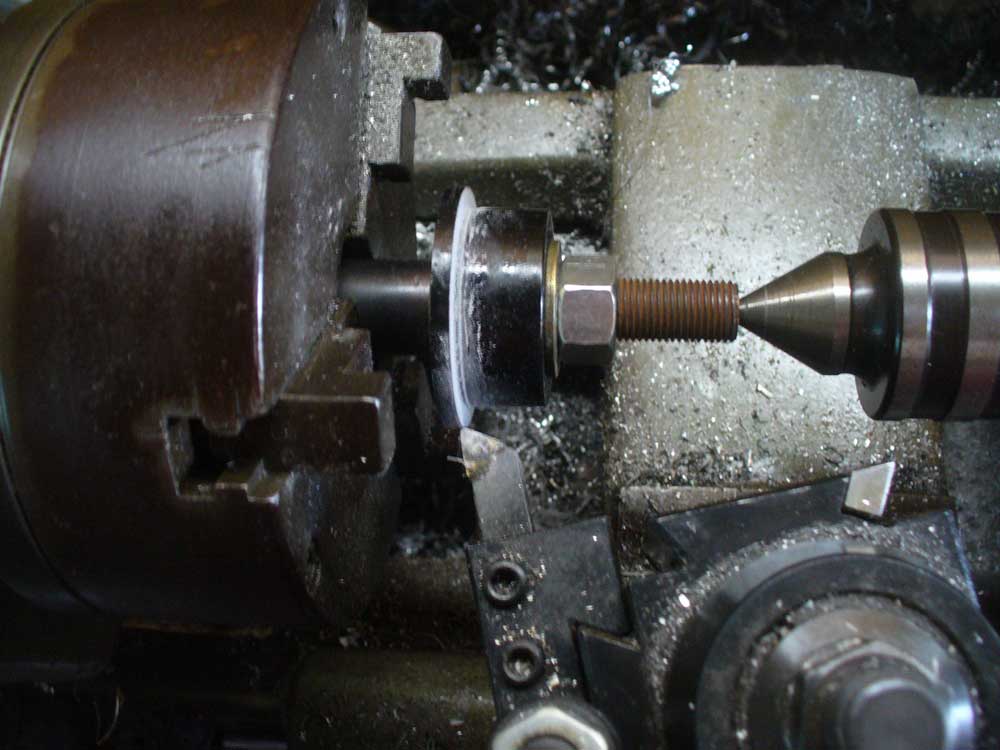

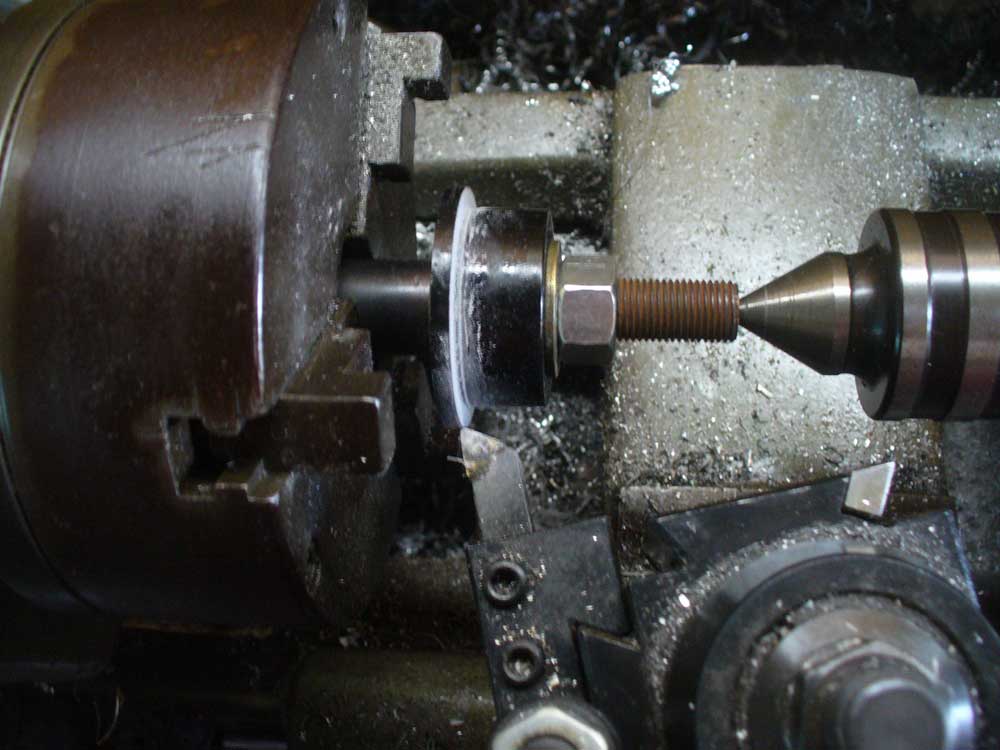

I used a piece of a broken U-bolt to make my arbor, plus an aluminum bushing to fit the 7/8” ID of the bushings:

Set up on the lathe:

The machined KOR bushings in comparison to the replacement RE1685 bushings:

There was no way on earth these KOR bushings were going to go in without a press. In retrospect I probably should have turned down the OD while I had them on the lathe. I was short on time though. Note the squeeze out forming on the side. I got a bit of this on both halves.

Here you can see the minimal gap I was working to maintain:

Next up is drilling the hole for the 9/16” bolt. I recommend a good ½” drill motor with a side handle and a silver & deming bit. Then plan on spending some quality time deburring those holes, particularly inside the bracket. These tools were the most effective for that job:

I then ran a test fit of the bolt just to get a feel for how everything should align. Note where the flag nut starts to interfere with the track bar bracket:

Here is why it interferes 3/8” before it starts to snug down:

It would have been nice if Kevin’s Offroad had seen fit to add the second bend, but I am sure that would cost more to produce. This is what happens when you tighten it down to the final torque spec:

It will be interesting to see what happens when I take it apart someday. I expect at least one of the welds has broken. But it did go together, and this did resolve my death wobble issue.

Here are the dimensions of the three bushing kits I ordered. These were measured with cheap digital calipers and taken from spots were middle of the range on those parts which had some variation. This should give someone at least a ballpark sense of the differences between options.

as a Rubicon Express, RE1600 track bar. Google searches suggested that the Moog K3176 bushings were an option. Rubicon Express offers a replacement bushing kit as P/N RE1685. Additionally I was curious to see if I could make the Kevin’s Offroad KOR-9906-HW (9/16” track bar bolt kit) and KOR-1179-KIT (Extra hard bushing kit) work with the RE-1600 track bar. So I ordered all three kits.

as a Rubicon Express, RE1600 track bar. Google searches suggested that the Moog K3176 bushings were an option. Rubicon Express offers a replacement bushing kit as P/N RE1685. Additionally I was curious to see if I could make the Kevin’s Offroad KOR-9906-HW (9/16” track bar bolt kit) and KOR-1179-KIT (Extra hard bushing kit) work with the RE-1600 track bar. So I ordered all three kits.I swear I took a picture of all three kits together, but doggoned if I can’t find it. It is probably mixed in with pictures of The Varmints somewhere and will show up when I am trying to put together a family calendar next December.

I do at least have measurements of all three kits. I will post those at the end.

The Moog K3176 parts strike me as junk. The bushings are very soft and the spacer is a piece of rolled sheet metal that is not even welded at the seam, nor is it even round. It might be a reasonable option if someone needed to be able to find a part while travelling, just for the sake of getting back home, but I would not want to run it for long. Additionally, I think installing it would be a PITA. The flanges are too thick for proper fitment with the RE1600.

The Rubicon Express RE1685 would be the safest way to go, provided the bolt holes in the bracket on your axles are not wallowed out. Only problem is, after 20-30 years that isn’t a safe bet.

Bumping up to the 9/16” bolt was my primary reason for wanting to try to run the Kevin’s Offroad parts, but I knew I was going to have to deal with the thicker flanges. Polyurethane can be machined though. Here is what I did to upgrade my hardware:

That powdery rust is the evidence that things are moving. This is why I want to move up from the factory hardware. That is from movement between the bolt and the hole in the bracket:

Here is the width of the RE1600 track bar: 1 7/16”. This is why the Kevin’s Offroad parts are not a direct drop-in. 1 3/16” is what those parts are designed for.

The difference between the 1 3/16” and the 1 7/16” is made up in the flange thickness. The RE1600 uses a flange that is less than 1/8” thick. The easy way to get to that thickness would be to chuck up the bushing and simply machine down the outside faces. The downside of this approach is that it would result in a larger gap inside the track bar. Better to mount the bushings on an arbor and then turn down the inside face of the flange. This way the overall thickness of the bushing remains unchanged and the gap in the middle is kept to a minimum.

I used a piece of a broken U-bolt to make my arbor, plus an aluminum bushing to fit the 7/8” ID of the bushings:

Set up on the lathe:

The machined KOR bushings in comparison to the replacement RE1685 bushings:

There was no way on earth these KOR bushings were going to go in without a press. In retrospect I probably should have turned down the OD while I had them on the lathe. I was short on time though. Note the squeeze out forming on the side. I got a bit of this on both halves.

Here you can see the minimal gap I was working to maintain:

Next up is drilling the hole for the 9/16” bolt. I recommend a good ½” drill motor with a side handle and a silver & deming bit. Then plan on spending some quality time deburring those holes, particularly inside the bracket. These tools were the most effective for that job:

I then ran a test fit of the bolt just to get a feel for how everything should align. Note where the flag nut starts to interfere with the track bar bracket:

Here is why it interferes 3/8” before it starts to snug down:

It would have been nice if Kevin’s Offroad had seen fit to add the second bend, but I am sure that would cost more to produce. This is what happens when you tighten it down to the final torque spec:

It will be interesting to see what happens when I take it apart someday. I expect at least one of the welds has broken. But it did go together, and this did resolve my death wobble issue.

Here are the dimensions of the three bushing kits I ordered. These were measured with cheap digital calipers and taken from spots were middle of the range on those parts which had some variation. This should give someone at least a ballpark sense of the differences between options.