Got the flat plates that will bolt to the block done.

Blank templates.

Only took a pic of the pass side...didn't think to take a pic of the driver's side

Also cut them out using this torch I bought over the summer, the

DHC 2000. Took me a while to get used to it and get the flame tuned correctly, but it cuts almost as well as a plasma provided you have a steady hand and only cost me $340 all said and done.

That slag flies right off with a file, or if stubborn, a quick shot with the angle grinder.

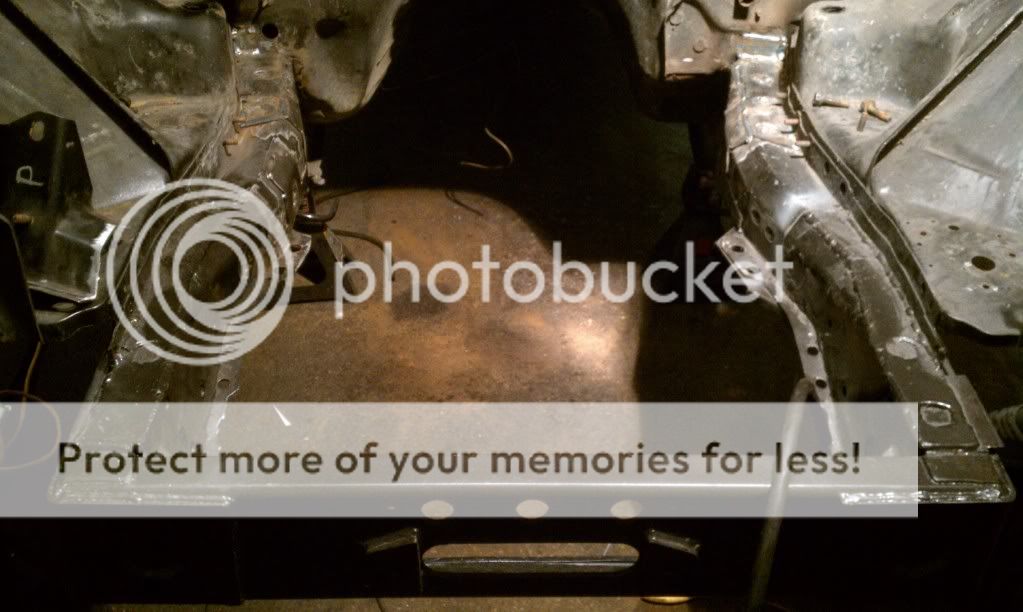

Saturday I'll make the tabs that grab the motor mounts themselves, tack them onto the flat plates, set the 4.0 in the engine bay to check alignment, then burn them in. After that, bolt the NP435 behind it, drop it back into the engine bay, and cut out the floor for the shifter tower as well as align the frame side brackets for final welding to the inner plating.

Gonna be working that engine hoist quite a bit :laugh: