MoparManiac

NAXJA Forum User

- Location

- Amherst, NH

Stock dodge knuckles, representin'.

Hydro assist rules.

Yeah yeah yeah...

But who can resist bling?

Stock dodge knuckles, representin'.

Hydro assist rules.

yea, you will have more prettyness in your knuckles then my entire jeep

hate you

the following weekend is Fall Crawl.

X2arty:

the rest of the stuff is cool too.

BIG AIR CONTEST!?

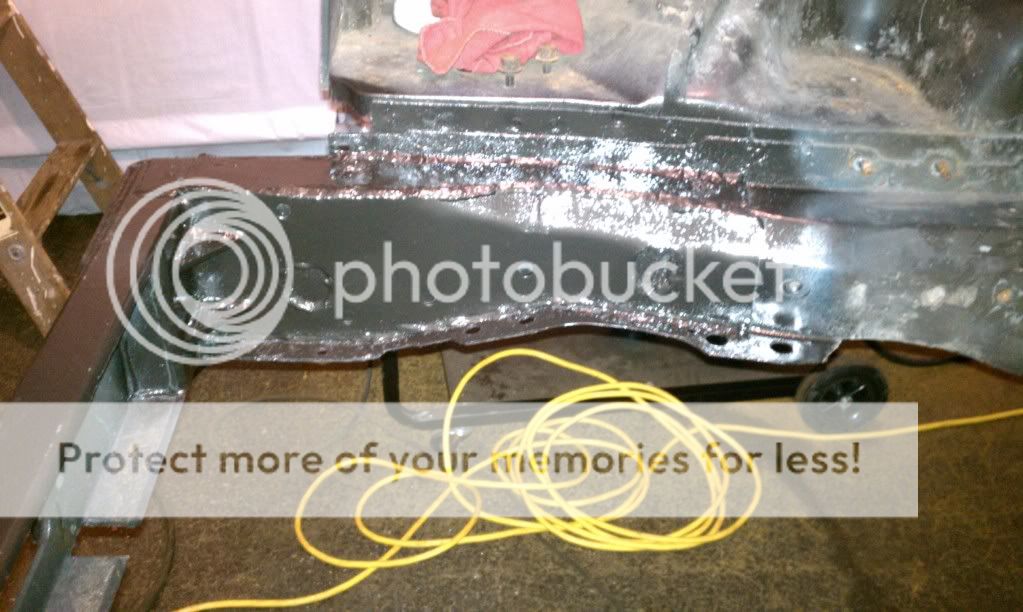

My welds were getting porous and spattering. Called Bill and he basically called me a retard and told me to change the tip :roflmao:. All better now.

I'm not that great at being a contortionist while welding.