Jeff 98XJ WI

NAXJA Forum User

- Location

- Butternut, WI

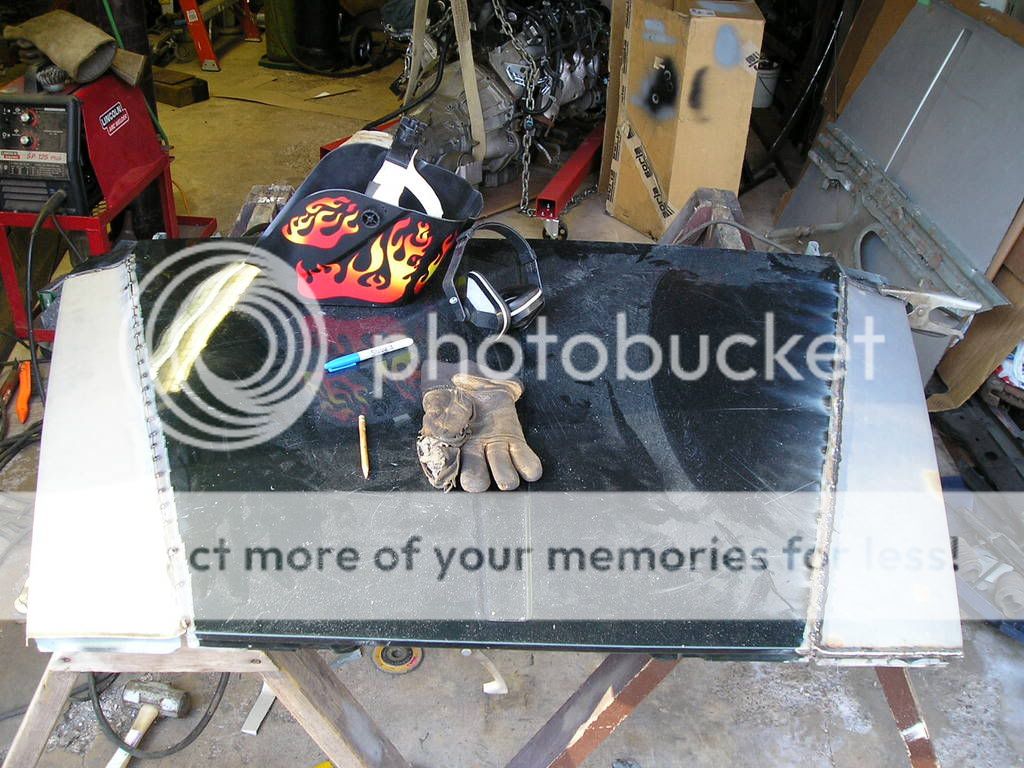

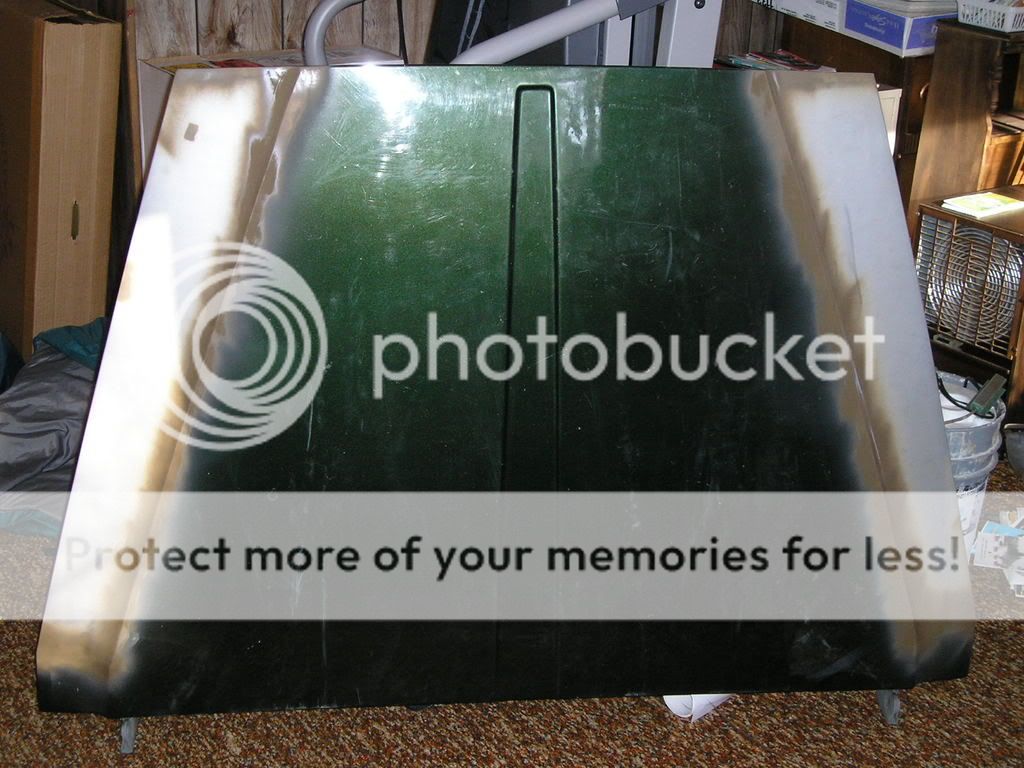

I played with hoods a little more the other night, so here are some shots.

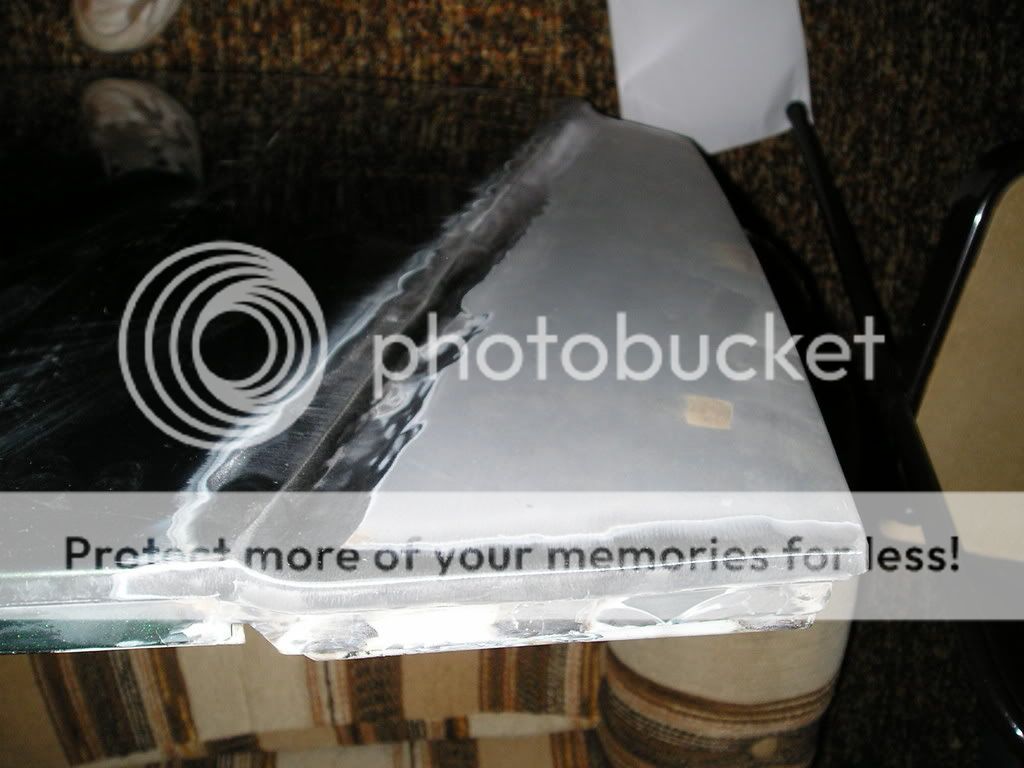

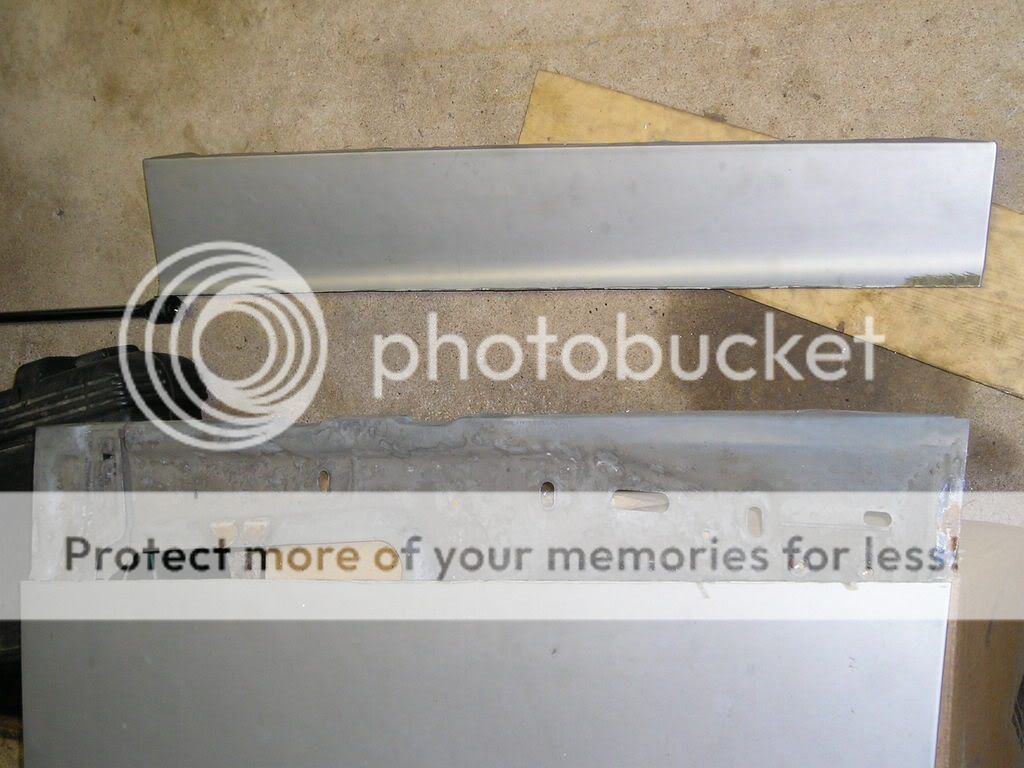

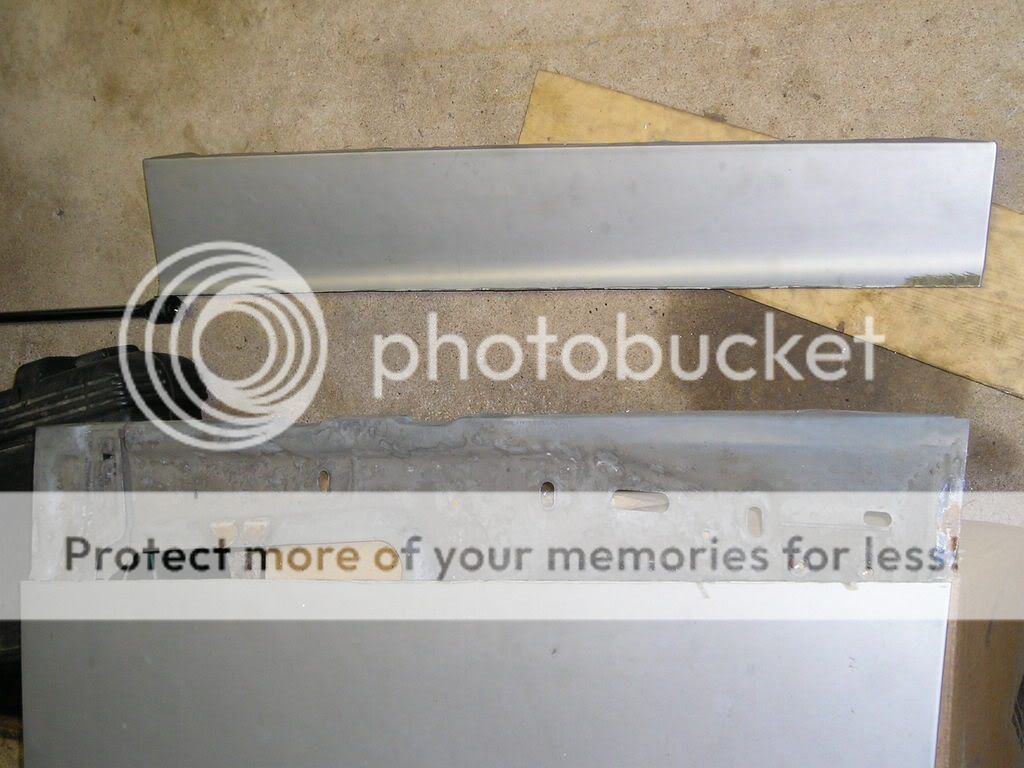

I ended up drilling out the spot welds and removed the section of hood I had cut.

It should go something like this on the other hood:

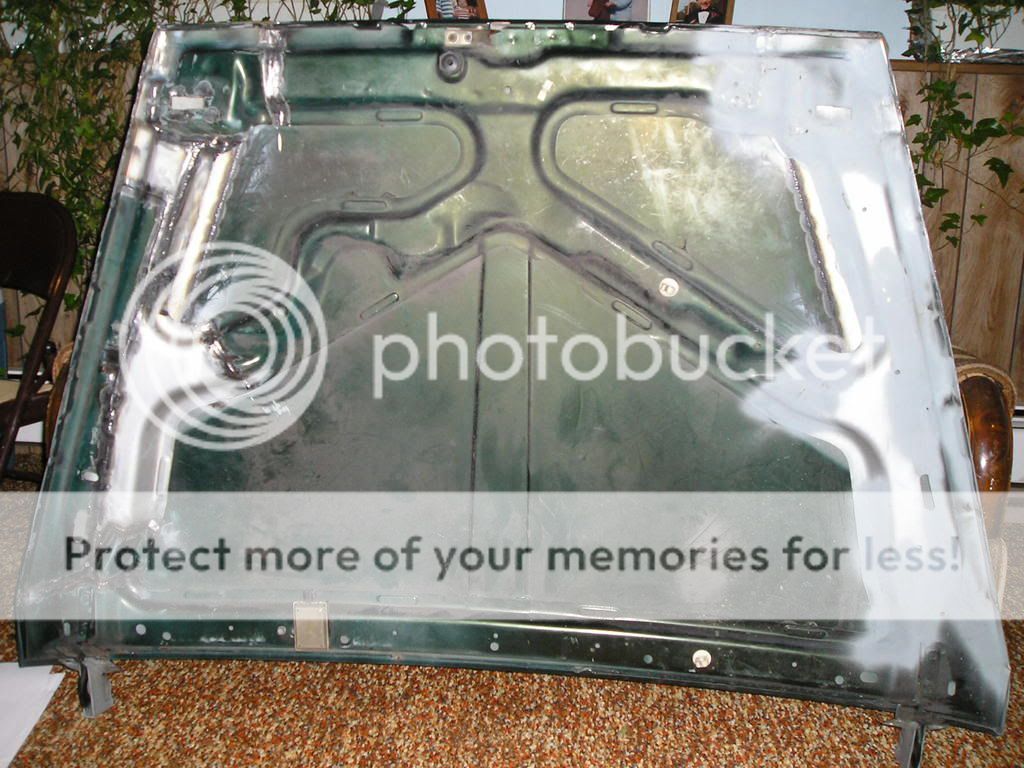

I drilled out the rest of the hood spot welds too but was having trouble getting the skin loose from the support where it was glued. I finally gave up. I did shoot a couple pics of the under hood support from above though.

Jeff

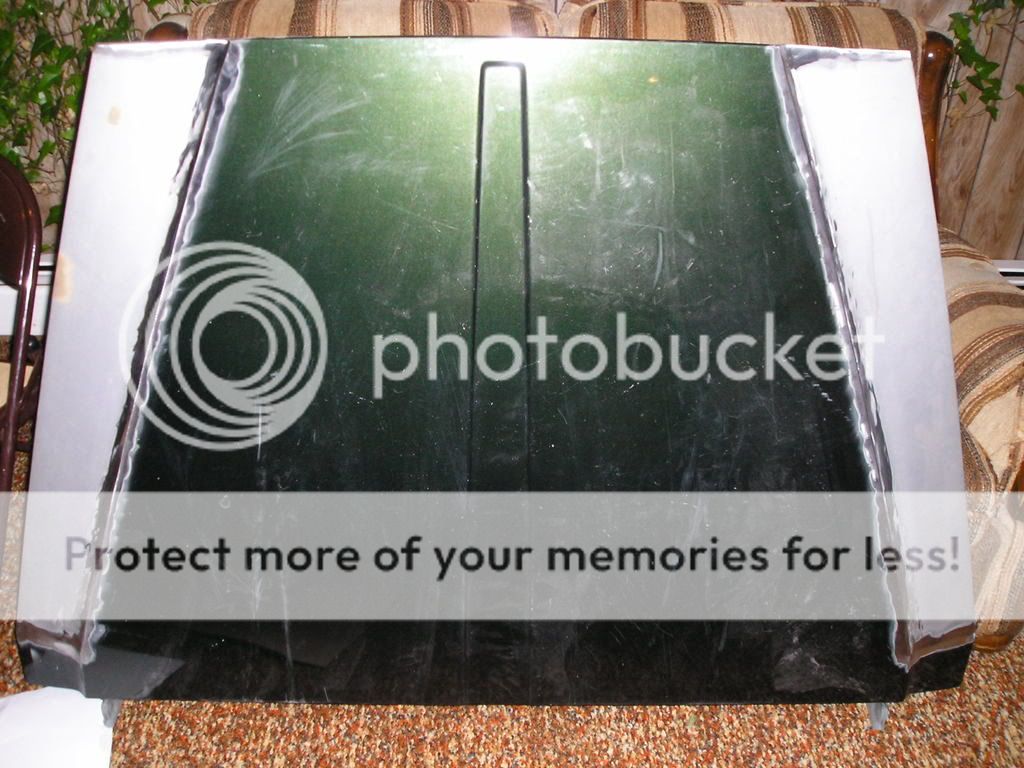

I ended up drilling out the spot welds and removed the section of hood I had cut.

It should go something like this on the other hood:

I drilled out the rest of the hood spot welds too but was having trouble getting the skin loose from the support where it was glued. I finally gave up. I did shoot a couple pics of the under hood support from above though.

Jeff