dgrigorenko

NAXJA Forum User

- Location

- Big Rapids MI

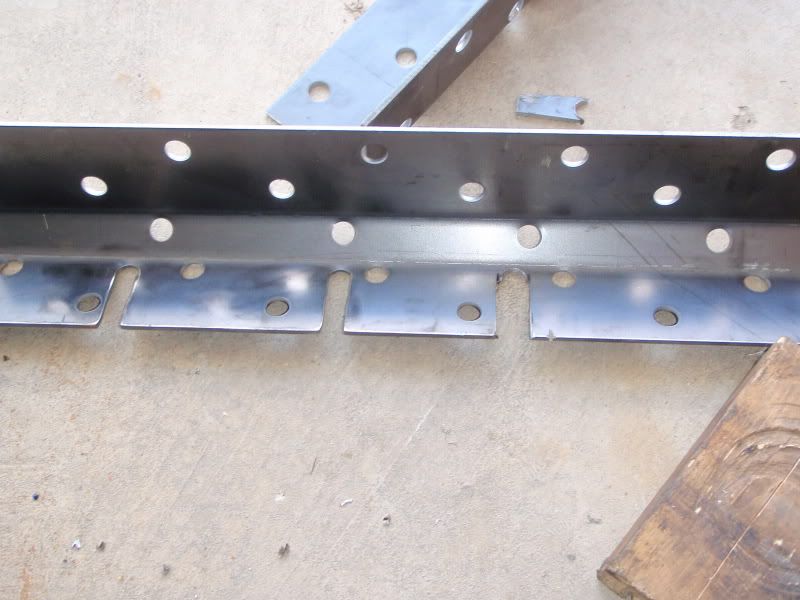

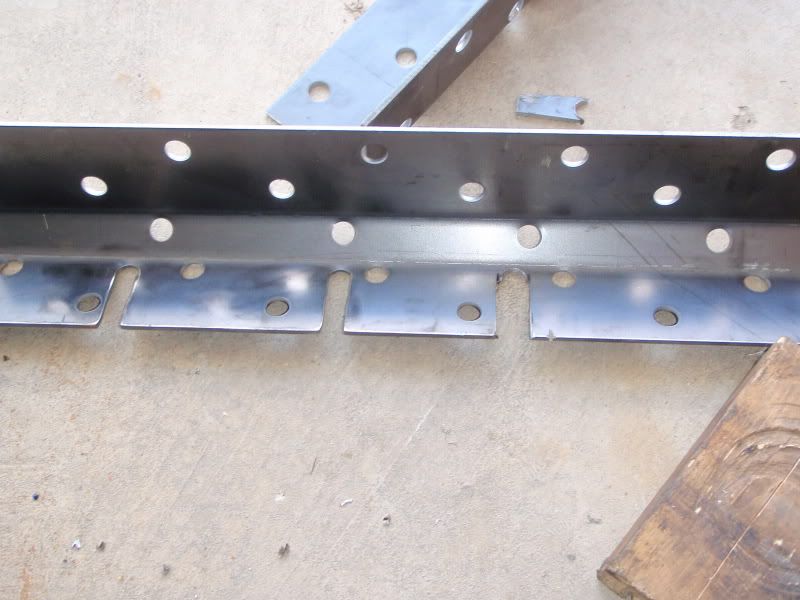

so basically i was getting tired of all the creaking that my jeep was doing even when going around corners, soooooo i went ahead and shelled out the clams (not that many for what you get), and got stiffeners from BRIANHO13 on www.hdoffroadengineering.com. here is what showed up:

at first glance i was pretty happy with what i got, although i was surprised at how light they were, but i suppose that could be because of the bazillion plug weld holes. these are made of 10ga sheet metal, which is slightly thicker than 1/8"(11GA), and slightly thinner than 3/16, which to me was a pretty good compromise of weight and strength.

one of the first things i had to do was modify where they had the crossmember bolt slots due to me having the TNT long arm kit:

next i had to start taking apart some of the crossmember mounting points, and cut off the crush sleeves to fit. i also decided not to completely drop the crossmember, instead i would just lower it enough to slide the stiffeners in

next came the really dirty part: cleaning off the rubber undercoating it went fairly quickly with an angle grinder and wire brush, but what id didnt take off was the paint, which i ended up being happy about. I decided that in order to keep some sort of protection from the elements i would only take off paint where i needed to, and not off the whole rail. i mocked up the stiffeners and with a sharpie i marked where all the plug welds were going to go, and only ground off where i needed to.

I also decided to use some of Krylon's "weld through" primer to prime the backside of my stiffeners. I used this not because i was planning on welding through it, but because it doesnt burn... this way there is still some weather protection, but still no paint where the welding is going to go...

Next came the mounting up... i only had 2 large C-clamps and a hydraulic floor jack, so i started at the front, would clamp and jack, spot weld, and then move back. this method seemed to work pretty well with getting things tight.

then there was the welding.... lots and lots of welding... and moving from side to side and front to back to make sure nothing got too hot.

let me tell you, there are a lot of plug welds on this thing....... IMO its kinda excessive, and something like the ones ruffstuff has is probably more than sufficient.

i then ground things down to smooth them out

Then i used some primer that i have heard good things about, this is the first time i have used it, so i guess i will find out how good it really is. Rustoleum self etching primer... first i cleaned it up with some acetone to make sure everything was squeaky clean, then coated it up. it had great coverage in my opinion so i am happy with it at this point.

I dont have any pics of it with final black paint on it, but i think we get the idea.

Overall thoughts on this install: not that hard, just some good ol grunt work. it took me about 3 evenings to complete, so thats not too bad either. I took it for a test drive and was VERY happy with the results. no more creaking when i drive over a man hole... i even took it up on a rock to flex it, and it barely made noise... this is a vast improvement from what it was. even just the feel on road driving is improved, it just feels much more solid than it was. now a couple of things to consider is that i do have the TNT belly skid tying these together which no doubt helps. I also have a very solid rear bumper, front bumper and the track bar brace, so there are a lot of things tying frame rails to frame rails. i think my next item on the list is plating from the back of these stiffeners to the bumper, and same on the front. i have not decided if i want to get the TMR ones or just make my own...

Final Note: i would like to thank as a whole, and all the writups that i have read to get my rig to where it is now, and doing it right... i am glad that i can give a little bit back.

as a whole, and all the writups that i have read to get my rig to where it is now, and doing it right... i am glad that i can give a little bit back.

G

at first glance i was pretty happy with what i got, although i was surprised at how light they were, but i suppose that could be because of the bazillion plug weld holes. these are made of 10ga sheet metal, which is slightly thicker than 1/8"(11GA), and slightly thinner than 3/16, which to me was a pretty good compromise of weight and strength.

one of the first things i had to do was modify where they had the crossmember bolt slots due to me having the TNT long arm kit:

next i had to start taking apart some of the crossmember mounting points, and cut off the crush sleeves to fit. i also decided not to completely drop the crossmember, instead i would just lower it enough to slide the stiffeners in

next came the really dirty part: cleaning off the rubber undercoating it went fairly quickly with an angle grinder and wire brush, but what id didnt take off was the paint, which i ended up being happy about. I decided that in order to keep some sort of protection from the elements i would only take off paint where i needed to, and not off the whole rail. i mocked up the stiffeners and with a sharpie i marked where all the plug welds were going to go, and only ground off where i needed to.

I also decided to use some of Krylon's "weld through" primer to prime the backside of my stiffeners. I used this not because i was planning on welding through it, but because it doesnt burn... this way there is still some weather protection, but still no paint where the welding is going to go...

Next came the mounting up... i only had 2 large C-clamps and a hydraulic floor jack, so i started at the front, would clamp and jack, spot weld, and then move back. this method seemed to work pretty well with getting things tight.

then there was the welding.... lots and lots of welding... and moving from side to side and front to back to make sure nothing got too hot.

let me tell you, there are a lot of plug welds on this thing....... IMO its kinda excessive, and something like the ones ruffstuff has is probably more than sufficient.

i then ground things down to smooth them out

Then i used some primer that i have heard good things about, this is the first time i have used it, so i guess i will find out how good it really is. Rustoleum self etching primer... first i cleaned it up with some acetone to make sure everything was squeaky clean, then coated it up. it had great coverage in my opinion so i am happy with it at this point.

I dont have any pics of it with final black paint on it, but i think we get the idea.

Overall thoughts on this install: not that hard, just some good ol grunt work. it took me about 3 evenings to complete, so thats not too bad either. I took it for a test drive and was VERY happy with the results. no more creaking when i drive over a man hole... i even took it up on a rock to flex it, and it barely made noise... this is a vast improvement from what it was. even just the feel on road driving is improved, it just feels much more solid than it was. now a couple of things to consider is that i do have the TNT belly skid tying these together which no doubt helps. I also have a very solid rear bumper, front bumper and the track bar brace, so there are a lot of things tying frame rails to frame rails. i think my next item on the list is plating from the back of these stiffeners to the bumper, and same on the front. i have not decided if i want to get the TMR ones or just make my own...

Final Note: i would like to thank

as a whole, and all the writups that i have read to get my rig to where it is now, and doing it right... i am glad that i can give a little bit back.

as a whole, and all the writups that i have read to get my rig to where it is now, and doing it right... i am glad that i can give a little bit back. G