YELLAHEEP

NAXJA Forum User

- Location

- Littleton, Colorado

Started working on my daily driver project and the main issue was the light front collision that needed repaired. Because the lower part of the pass. frame end was not only pushed back, but had collapsed inward on itself causing tearing on the bottom edge, I didn't feel this was repairable by using a frame jig. Maybe I was wrong, but anyway, here's what I did to repair it - body guys, feel free to critique and also of note, I'll be installing a winch bumper to this XJ - yes, it has the longer frame mounts and won't just be mounted to the stock bumper holes.

Damage after stripping away the parts. You can see the line where I'll make the cut:

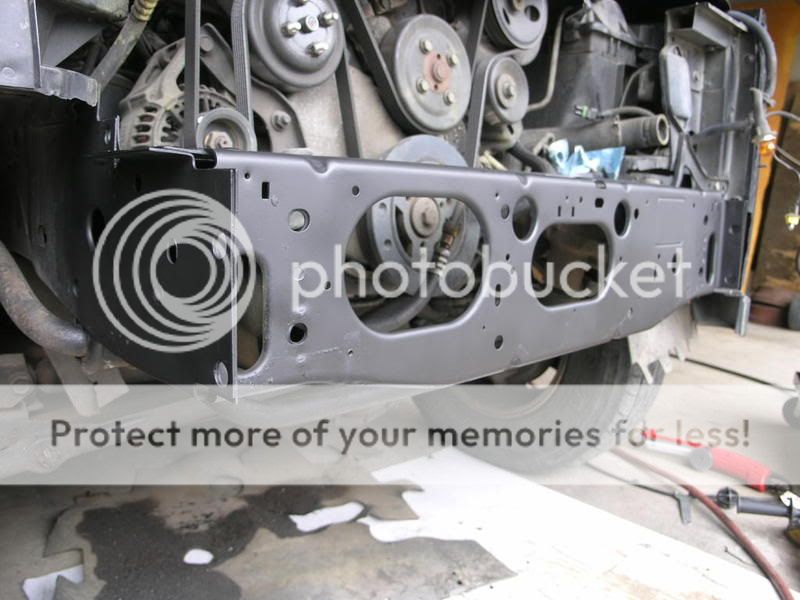

Good section of frame ends and crossmember from a donor XJ:

After the cut. A few minutes with a hammer/dolly and pry bar got the outside straightened out. I drilled out the spot welds and ground off the bead weld on the driver's side to install the replacement crossmember as the factory did:

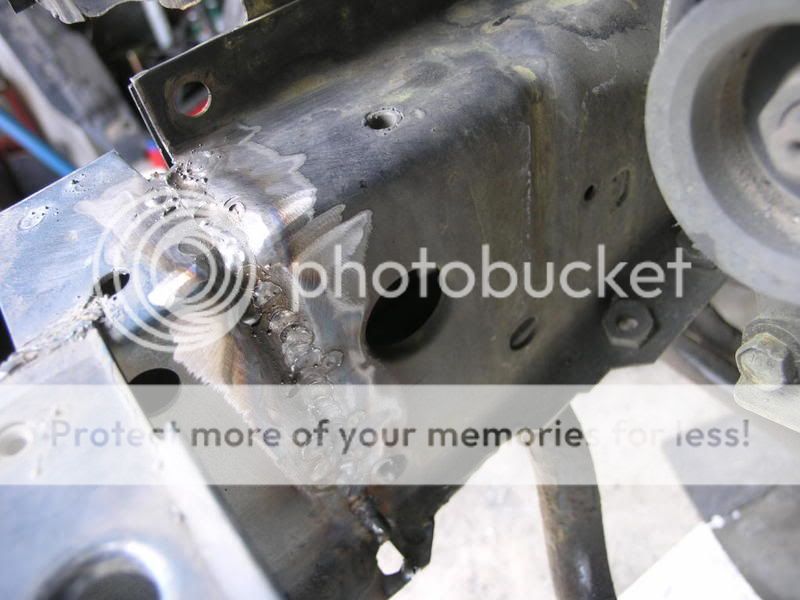

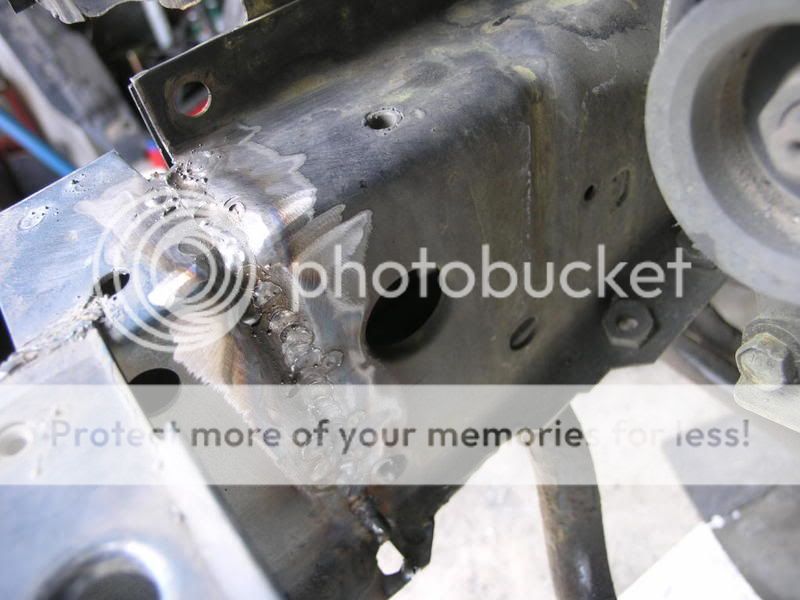

I certainly didn't want to simply butt-weld the new section to the old frame section so I "sleeved" it to give the seam a metal backing - something for the bead to burn into. I rosette welded the sleeve parts in place:

Here's the new section burned in:

The inside - not as pretty as it was hard to work around the alternator (shoulda just removed it to give me some room.....)

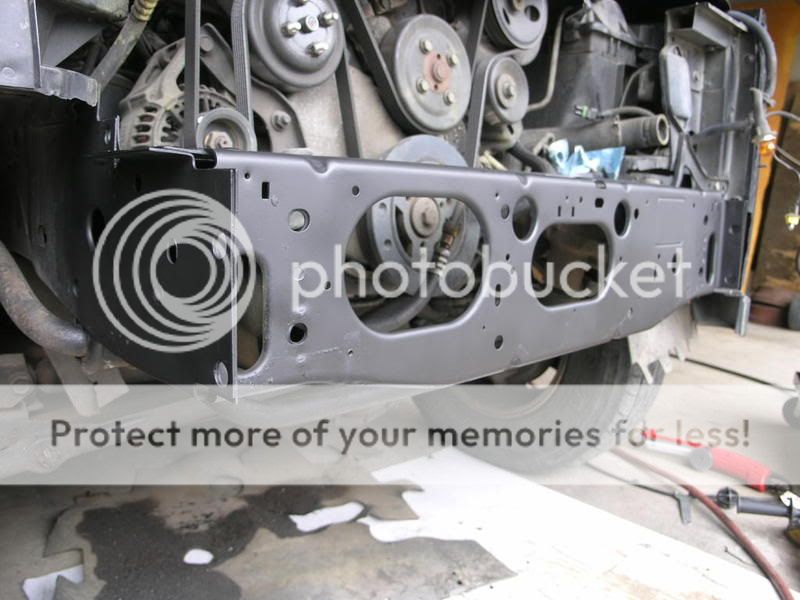

Here it is all finished and painted. Hopefully I won't have it crack apart on me, but I'd think that the winch bumper should actually reinforce it a bit.... :dunno:

Comments?

Damage after stripping away the parts. You can see the line where I'll make the cut:

Good section of frame ends and crossmember from a donor XJ:

After the cut. A few minutes with a hammer/dolly and pry bar got the outside straightened out. I drilled out the spot welds and ground off the bead weld on the driver's side to install the replacement crossmember as the factory did:

I certainly didn't want to simply butt-weld the new section to the old frame section so I "sleeved" it to give the seam a metal backing - something for the bead to burn into. I rosette welded the sleeve parts in place:

Here's the new section burned in:

The inside - not as pretty as it was hard to work around the alternator (shoulda just removed it to give me some room.....)

Here it is all finished and painted. Hopefully I won't have it crack apart on me, but I'd think that the winch bumper should actually reinforce it a bit.... :dunno:

Comments?

Last edited: