- Location

- Torrance, CA

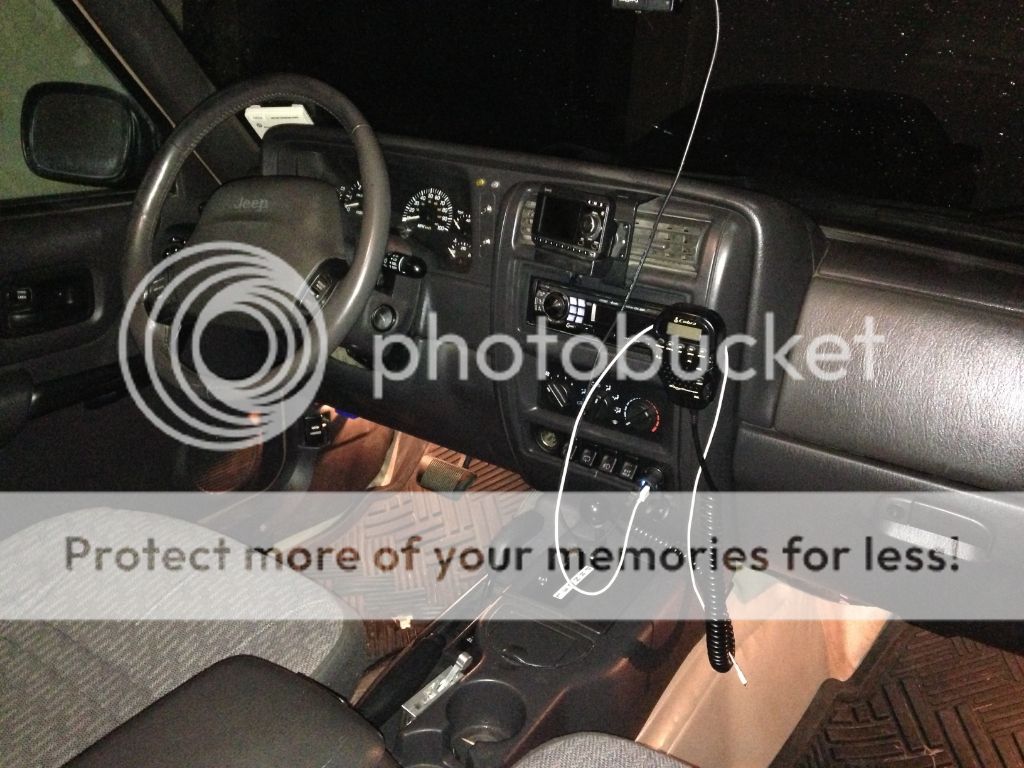

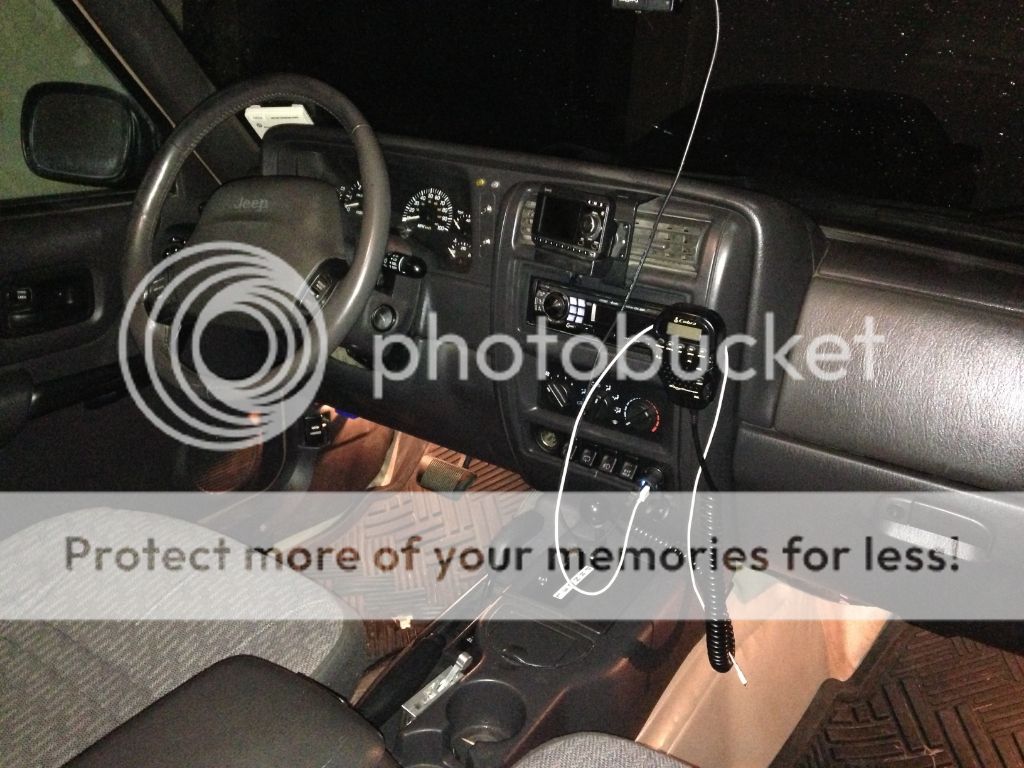

Two days so far with no CEL. :repair:

Last edited:

What I did was wire in 100 ohm resistor between each solenoid output from the TCM and ground. So far this week, no CEL's so far and I've run 1st and 2nd out to the limiter a few times.

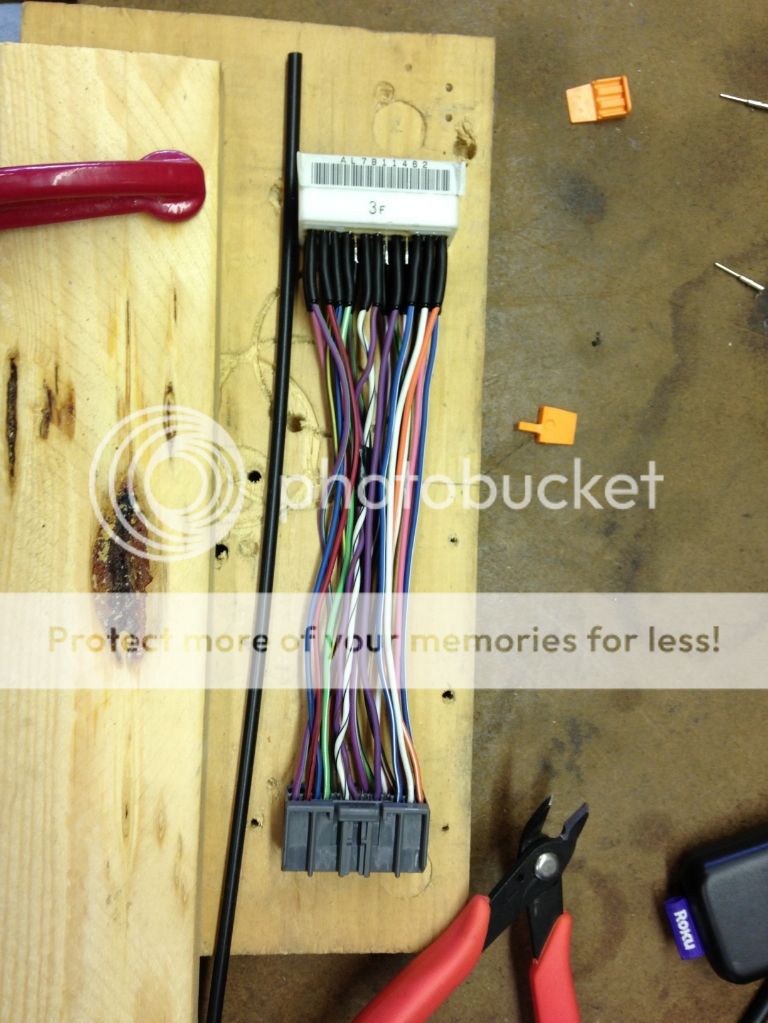

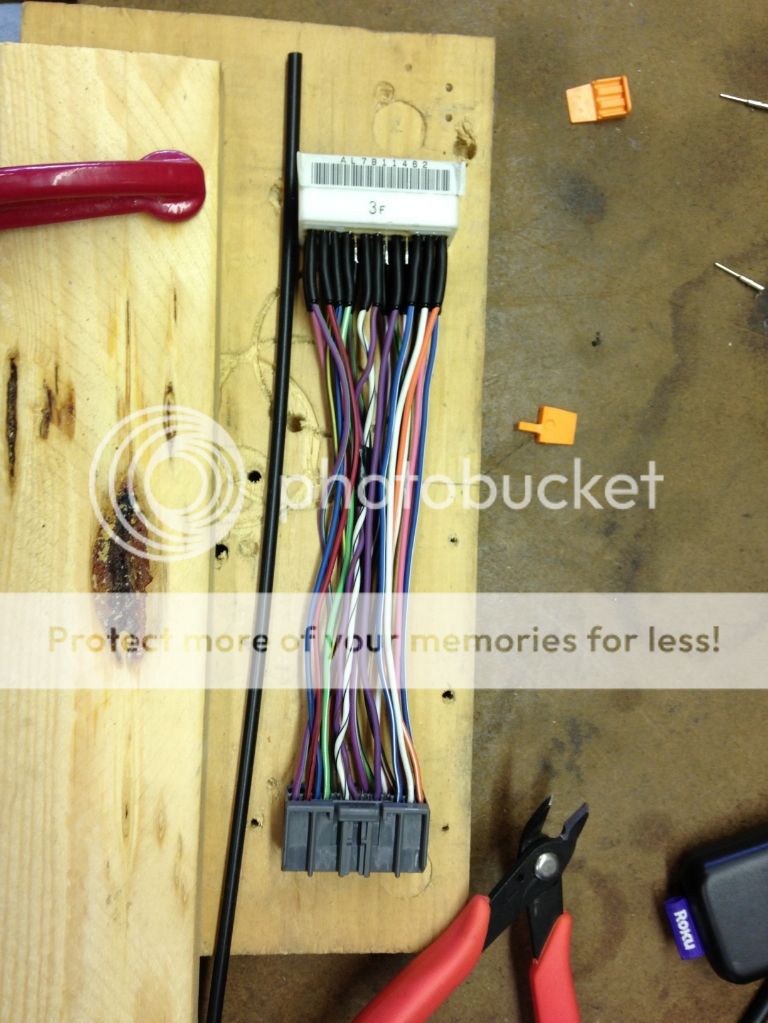

That's a great setup. I've seen a couple guys try something similar as did I but I haven't heard of anyone before getting 100% positive results. Did you seriously hack up a 2nd harness for this?

When I tried this method on my 98 I got codes after several days if the TCU asked for second and I asked for third or vise versa. Iirc they were solenoid function codes not electrical fault codes. The difference being that a solenoid function code means the trans isn't in the requested gear, while an electrical fault code is the one where the TCU sees the short or open circuit.

Maybe you just have better luck than me. I may try it again for a while before I drop my ax15 swap in, the last time I tested that method was in 2010 about when raneil did this setup, after that I tested a few modifications to the TCU itself with slightly better (but still not 100%) success.

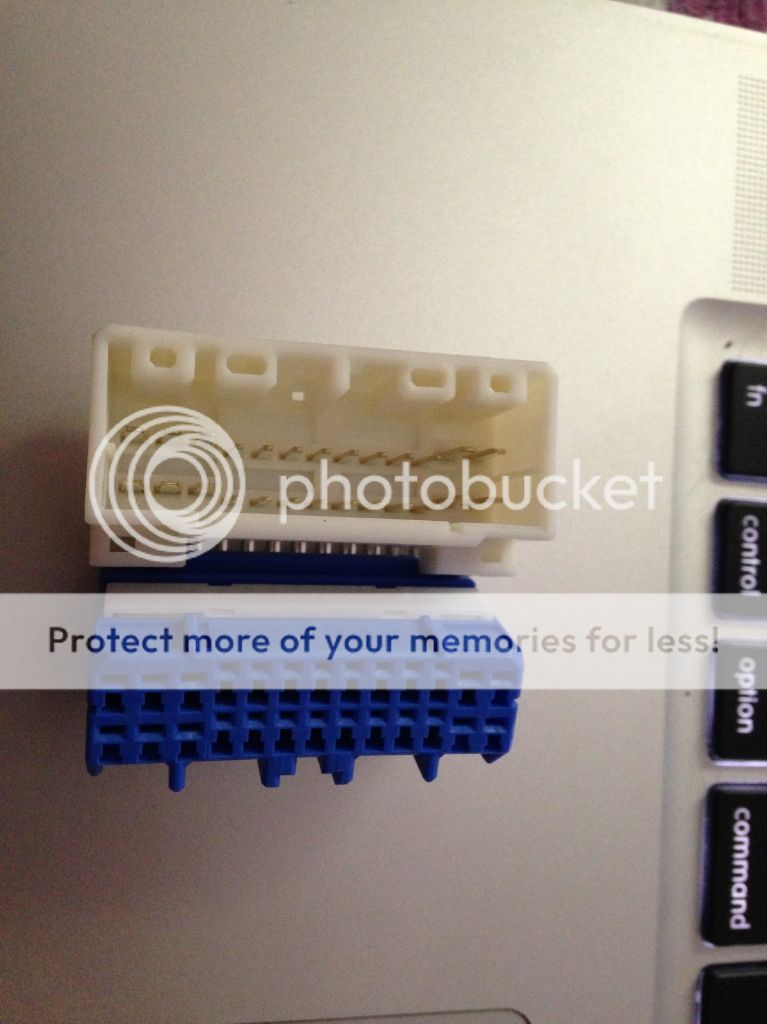

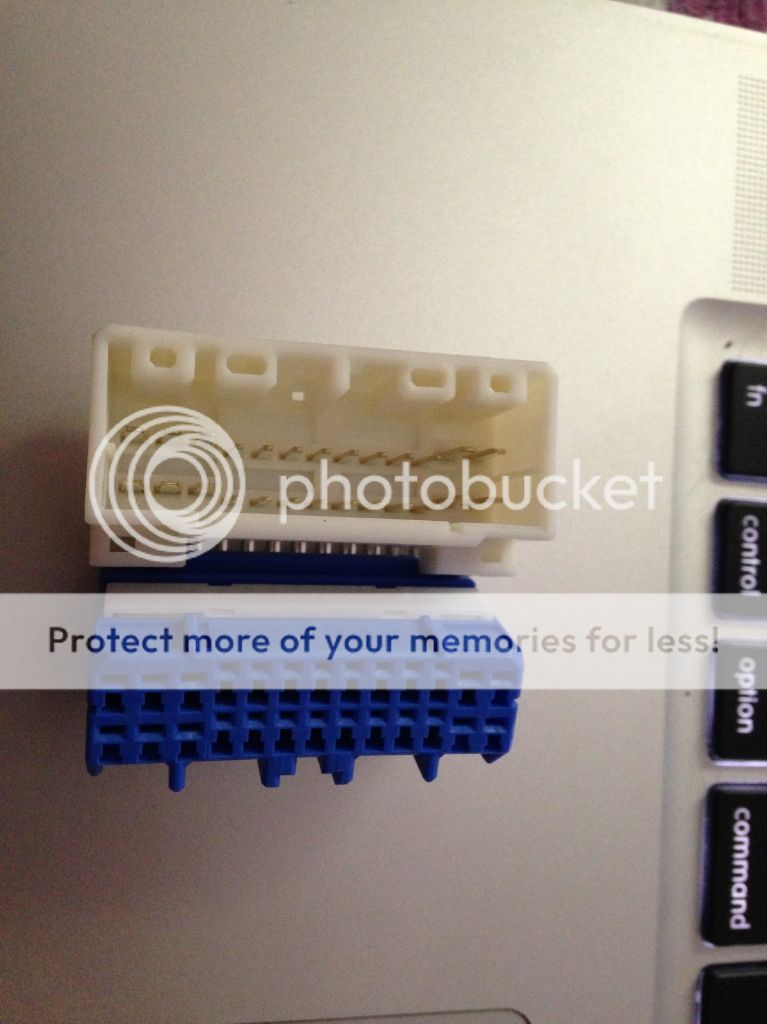

Thanks, Yes I did hackup a second harness and TCU to build my patch harness. I have since ordered up the connectors to build more patch harnesses.

Do the function codes set a CEL? I know when I would get electrical fault codes the TCU would no longer use that solenoid and pretty much go into limp mode till I reset the TCU. This was the same on my 99 and the giveaway rig, which was also a 99. What is the part number of your 98 TCU? I'd be tempted to find one and test it on my rig.

I believe it's the same as a 99 TCU, but will have to check when I get home. P56041386AA ring a bell? Not entirely sure on that number, so don't put much stock in it.

It definitely set a CEL for me - anytime I was driving like a jackass (occasional heavy throttle, etc) while shifting manually between 2/3 with my tiptronic setup, the TCU would get pissed off if I didn't agree with it.