Got quite a bit done today.

All my fuel stuff, trans/case adapter and VSS, and alternator connector showed up. Went across the border to pick it up. Didn't know that the case adapter was in and AA didn't put a receipt or anything in the box, and I called my order in over the phone so I had no evidence as to price for customs, so I had to just hide it in the back of the mustang. No questions, right through. I can't believe I didn't get searched either direction in the most obvious of drug dealer cars.

The AA kit went in mostly smooth. The trans/case mount wasn't drilled out quite right and needed some holes lobed out but otherwise, she's in.

Assembling the trans/case/adapter.

Note, the 40 tooth reluctor installed.

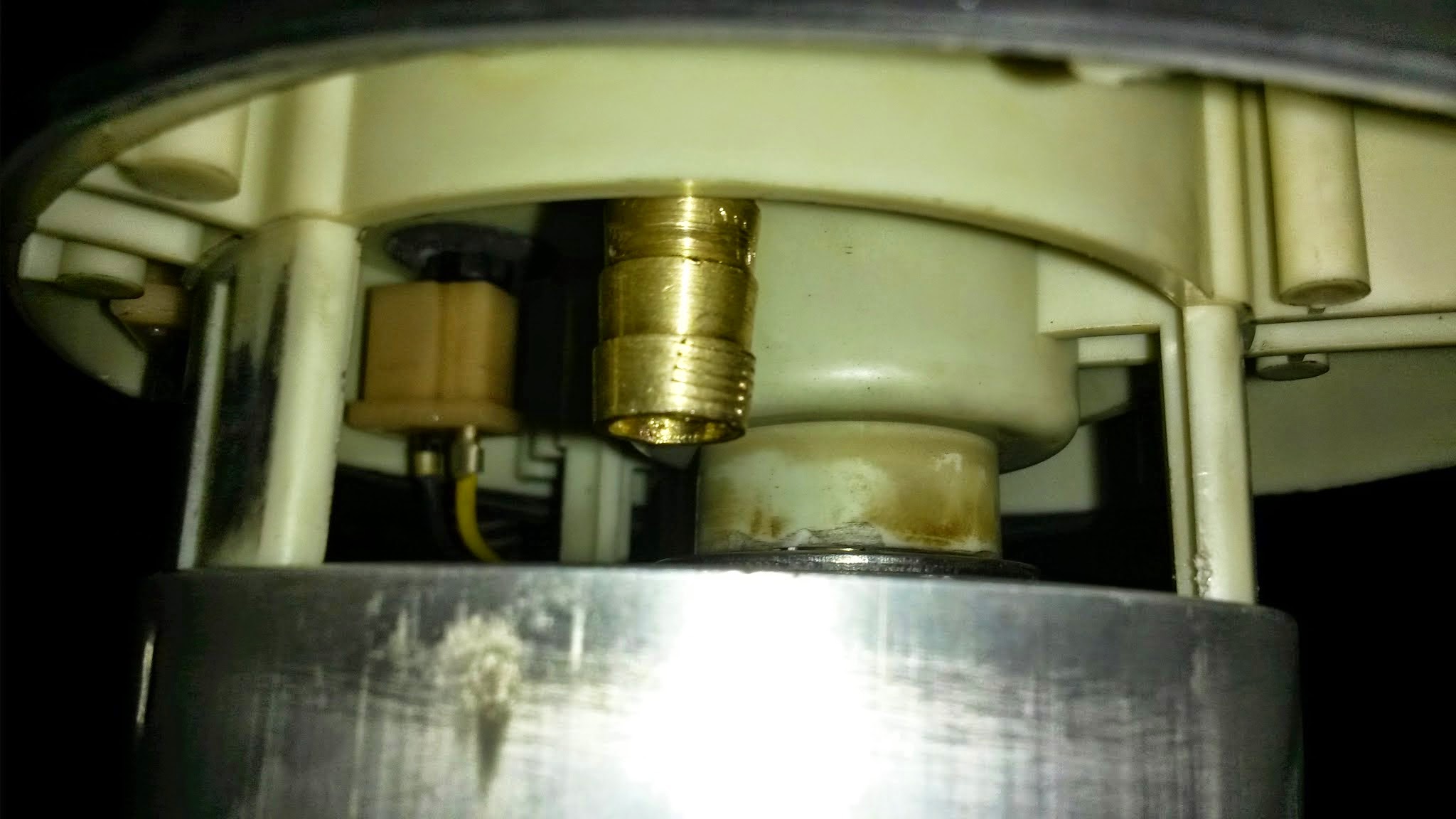

GM VSS lined up nicely.

And the whole assembly fit perfect with my hybrid case (np241c long input wide bearing 27 spline + 6 pinion planetary - 2000+ GMC 1500, np231 internals, wide input bearing, and shift lever - 1992 S10, and np231 case, main shaft, SYE - 1998 XJ). A few people told me that shaft either wouldn't have enough spline engagement, or too much, or would bottom out in the front of the case, or would be the wrong gear pitch. All wrong. Everything went perfect.

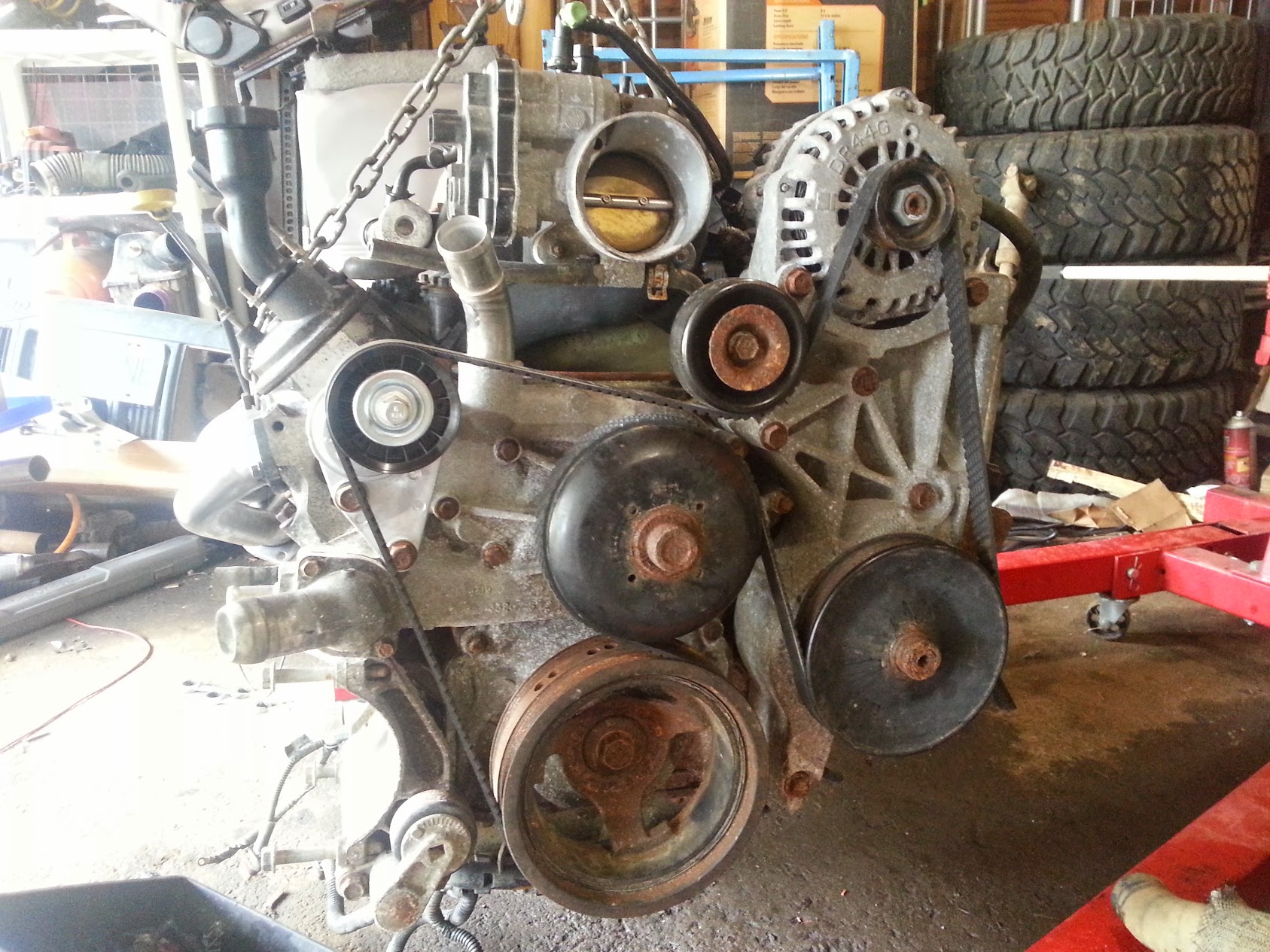

Stuck a belt and new tensioner on.

Dropped the fuel tank to install the Walbro 255lph pump. Tank was right full. Just invited everyone to pull up beside the Jeep, stuck a hose on the end of the fuel line and bumped the fuel relay. Topped up the mustang and the civic... Still over half full *sigh*. Figured half was enough.

Spent 20 minutes blowing out all the mud from everywhere around the hoses and connections with compressed air. Too cool for safety glasses. Spent another 20 minutes crying, cause sand.

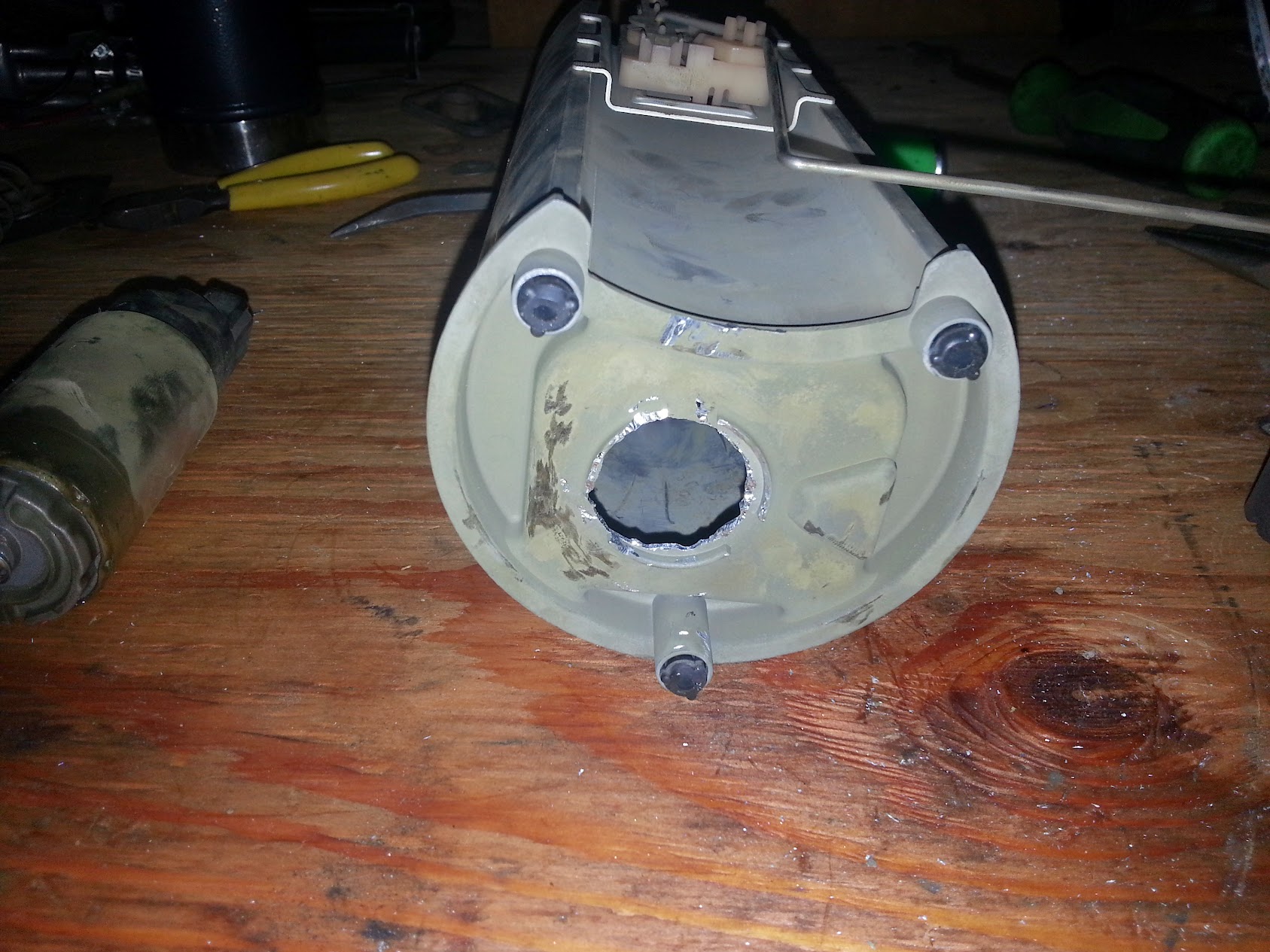

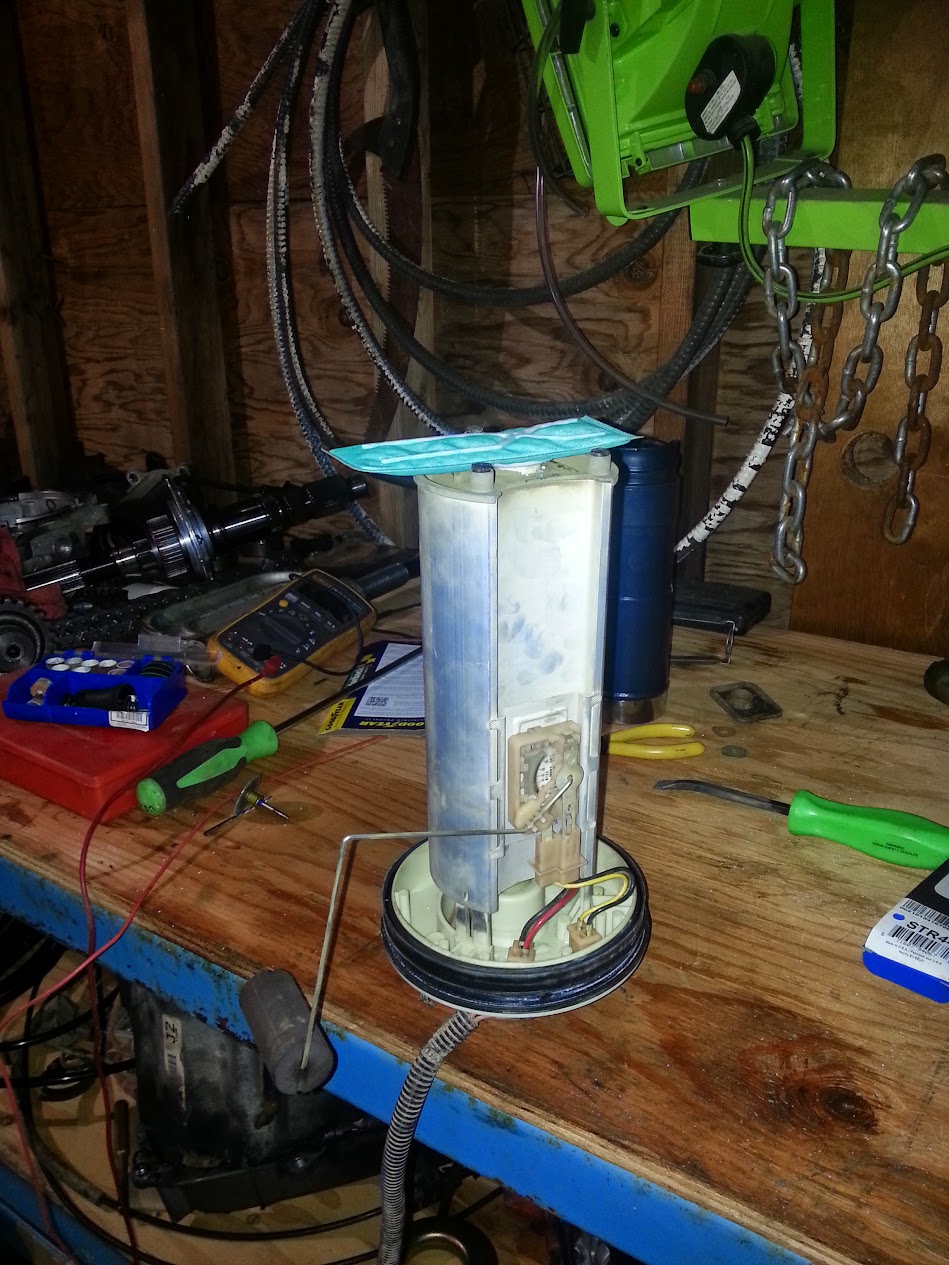

Once the tank was out, I popped the top off and removed/disassembled the pump canister.

Here's the Walbro beside the XJ (right)

Note, I already put the fuel hose/tube and spring on the Walbro.

Dremeled out the bottom of the canister to fit the Walbro pump. Took about 20 minutes for some reason.

As far as I can tell, this setup should work, but there are 3 tabs that stick up inside the canister that have to be chopped off as well so the Walbro can sit flat and seal to the bottom of the canister.

Walbro pump ready to be stuck into the canister.

Walbro in the can.

So the pump assembly is complete, but I still have to figure out the stock pressure regulator (which I assume is the silver part on the top of the assembly that I couldn't figure out how to remove). I've heard you can just drill something out on it and just pass fuel through unhindered. Anyone have any insight on this?

Also, I test assembled one end of the fuel hose. I tried the caulking gun with the brake line flare tool, but no luck. It just bent the shit out of the gun. Ball joint press worked WAY better. Really, what job can't be done with a ball joint press?

All in all, a not completely unproductive day. I'd hoped to get more electrical done, but Steve (the roomie/electrical guy who will just redo all my electrical if I try to do it without him) was busy with his lady all day.

I'm thinking it'd make sense to relocate the PDC to the drivers side, since that's where a majority of what's left of the harness is located. Then it'd just be 10 or so wires over the firewall to the HVAC firewall grommet. I think I'll probably locate the ECU between the fender well and the PDC which will be right behind the headlight (elevated as high as I can before hitting the hood).

One question came up today that I'm hoping someone can answer.

The GM ECU is pretty open in terms of programming. Is there any reason I couldn't just program the ECU to use the XJ fuel sending unit? It's just a matter of matching up circuit resistance with fuel level, so I can't imagine any good reason why not, but .. ya know.. I've never worked on a GM. Idea's?

If not, I'll hit the wrecker tomorrow for a GM unit to duct tape to my fuel pump canister.