- Location

- Thornton, CO

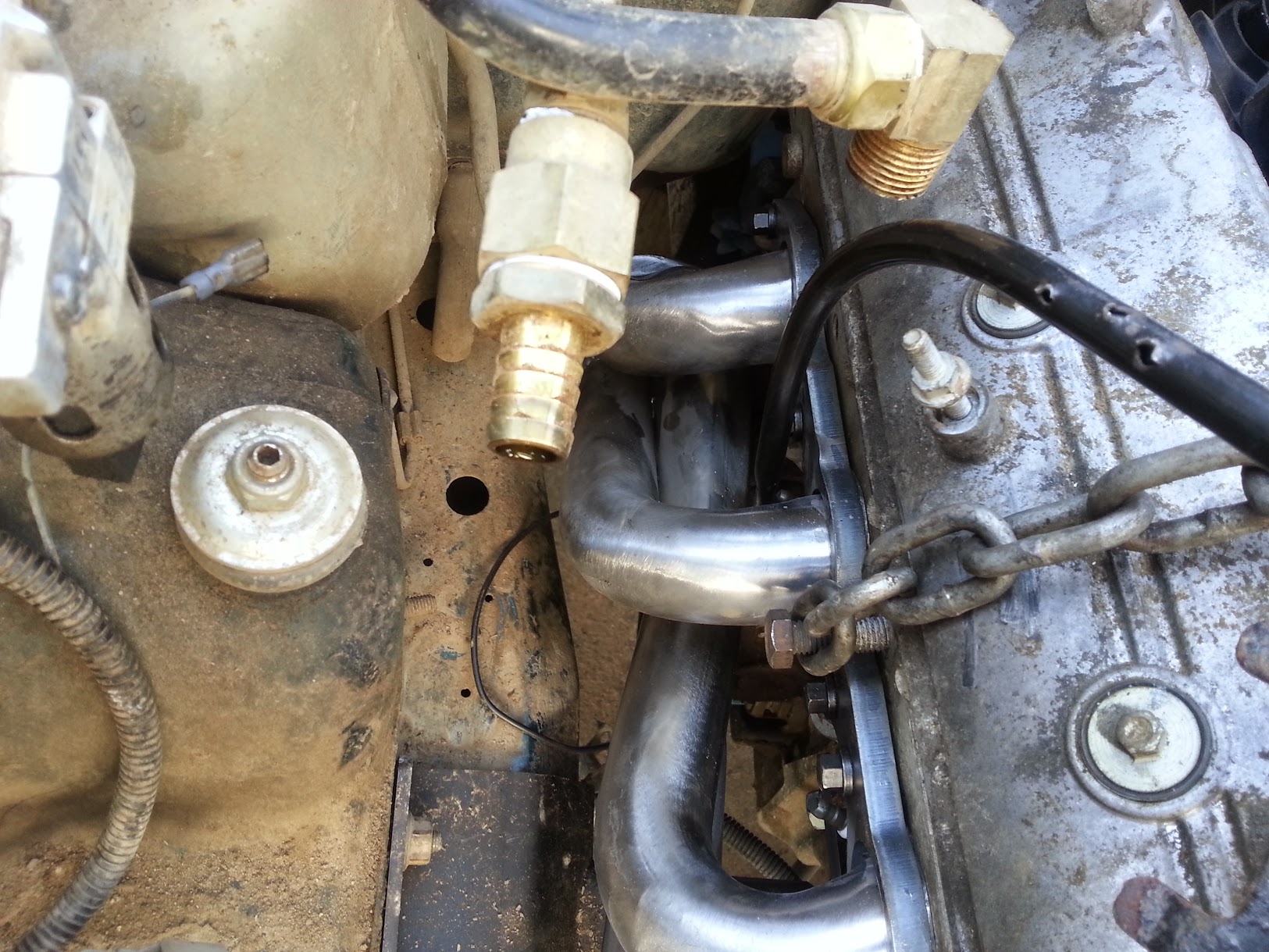

My not so pretty 5.3L............

It's okay, nothing that came out of that engine bay was pretty either. Keep up the good work.............:looney:

My not so pretty 5.3L............

if you have the vss on the transmission output, you just don't have a 4l signal because it doesn't matter. Yeah the Speedo is wrong but in 4l who cares. If you hook up a switch it will totally screw up your shifting because there's no way to read the change, so anytime you switch to 4l it would be doing calculations that are completely wrong for shifting, but right for the speedometer. Remember it's using output from the transfer case so to get the speedometer right you will be telling it the output revs are multiplied even though the signal its receiving never changed. I think it actually might be so confused the shifting would be completely fubar. Hell it's confusing me just trying to think about it

Right. Duh. Makes sense. What I wanna know is why they put the VSS on the t-case output for 4wd applications, when it clearly belongs on the transmission output.

I think my next question should be about the motor. I hooked up the starter and bumped it, but I have no idea how fast it should be turning over. Seems a bit slow. Does the 05 starter (stock) require shims?

The narrow bearing works fine on the older input shaft, I just used a narrow bearing on my older 242 no problem. I don't think a wide bearing will work right with a newer one, because less surface area on the shaft, but I don't know for sure, it might work fine.The big question here though is the wide bearing. IIRC, the early 231 used a wide bearing and the late model used a narrow bearing. I've heard that the bearing doesn't matter and that it'll fit either case, but I've never actually tried to do this before. Does anyone happen to know which combination (if any) will work?

FWIW I was talking about how low the bottom of the truck pan sits in relation to the ground or bottom of the axle, not the track bar. My track bar has plenty of space as well. It's something like an 8" deep pan which is about 3" deeper than the ls1 oil pan. How does the bottom of the pan look on yours under full weight? It's probably fine at 6.5" but based on mine I think I would still be concerned about dragging it on something.