Hi Guys,

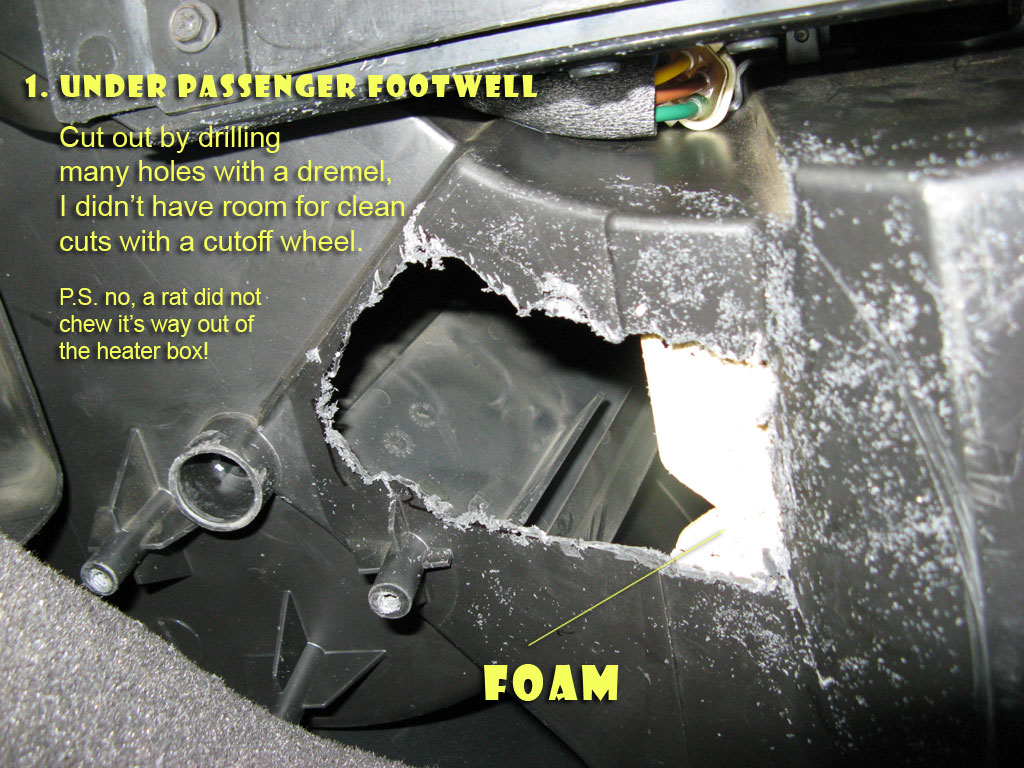

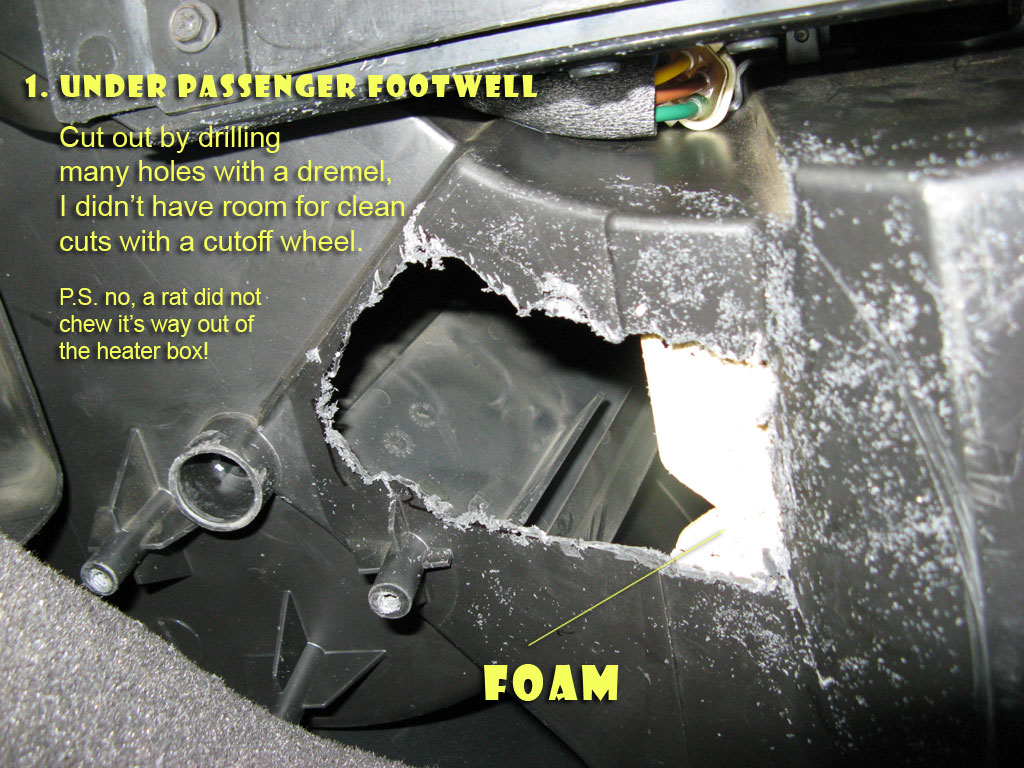

I finally fixed the heater blend door in the 99 I've been working on! I'd like to thank the guys from Heater Treater first off, because they were gracious enough to send me the cutting template for the 97+ models. Without this for guidance, I wouldn't have attempted to cut into the heater box. Details and pictures below...

Long story short, I spent about 3 hours today cutting into the heater box, experimenting with fixes for what I observed to be the problem and then putting it all back together to get a working heating/cooling system again.

Summary of situation

Ok, so the hvac temperature was "kind of" working in this 99. It never got as hot as it should have, and sometimes the cold wasn't very cold either. After ruling out problems such as the thermostat and heater core, I knew this was probably the infamous blend door problem.

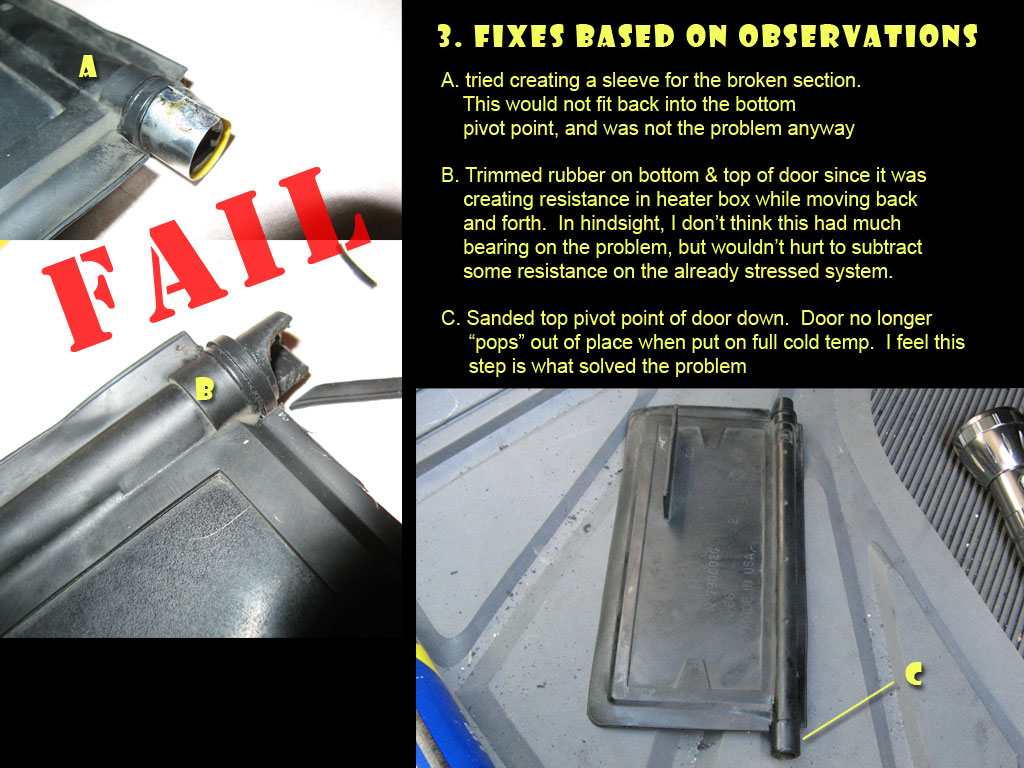

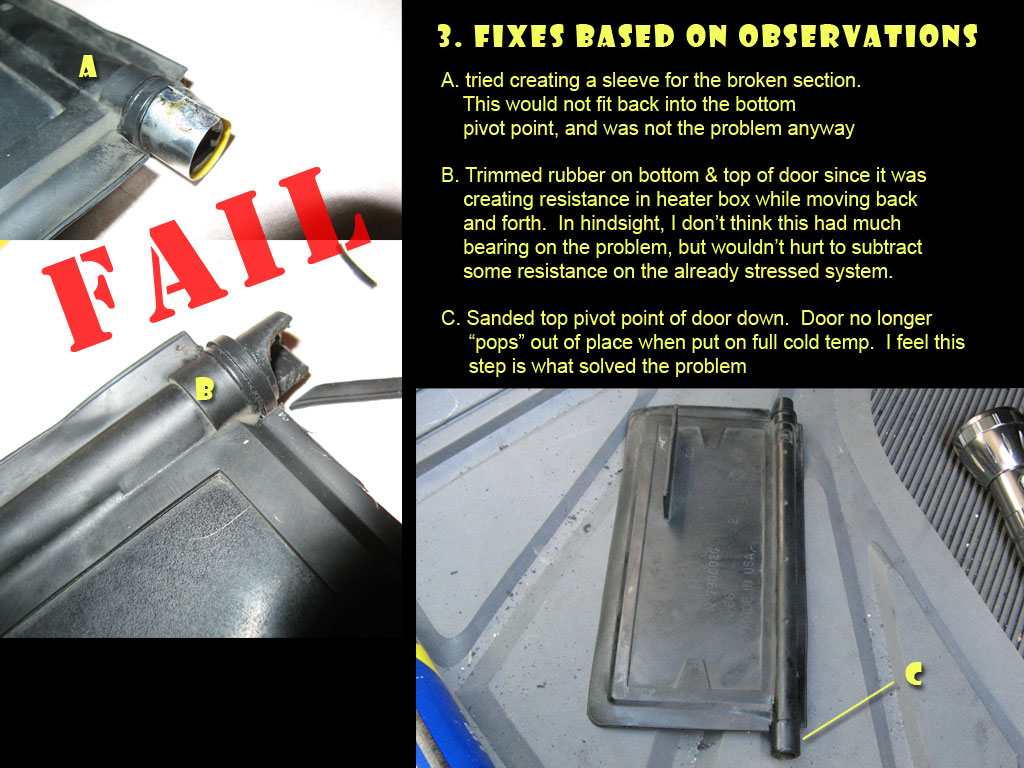

My motor was fine, but part of the blend door shaft was broken. I originally thought that since a section of the shaft was broken, that when it cycled on that side, it created a temporary weak point, then the door popped out of position. Ultimately, I don't think that was the issue at all. I believe that the MAIN problem was that the top shaft end of the

blend door was NOT fitting into the hole in the top of the heater box solidly. I tried to make a metal sleeve for the broken bottom shaft (old bus fuse tin made into a circle, then soldered and grinded/sanded down), but the clearance was not enough for it to fit back into the bottom shaft pivot point.

The HARDEST part of this whole job was putting the blend door back in the hole that you cut for access. You really need to get the bottom of the door in the bottom pivot point, then push the top in at an angle. It's really a nightmare procedure and my forearms are pretty tore up from wrestling with it multiple times.

Details I observed after cutting into the heater box and fix:

1. door seemed really tight. This seemed to be caused by the top and bottom flaps being taller than they needed to be. Within the heater box, the flaps were bent about 1/8 inch, that is they didn't clear the box, they were in there bent against the top and bottom. I realize this is to make a tight air seal, but I'm pretty sure it contributed to the problem in my case. I trimmed those as seen in the picture.

2. the MAIN problem with my door was that when it would be put to full cold, the actuator motor stressed, and then the top of the door would pop out of the pivot point EVERY time! I sanded the top part of the top shaft end down, and I honestly believe that this was the miracle cure. I really don't think the shaft was sitting tightly in the

hole at the top of the heater box before....it was just kind of wedged against the top and that's why the air was not going full hot or cold, but was still changing. It was working, but was not sealing completely off one way or the other.

To seal everything up, I used this black locktite tape called "sumo" that I found at walmart. It is a LOT more adhesive that duct tape, and seems very durable. Time will tell. If it doesn't hold up though I'll prob use that aluminum tape next time.

In my case, the problem is solved for now. If it fails in the future, I'll be buying the heater treater door, but I really couldn't afford the $120 right now, again, I really want to Thank the guys at heater treater for being nice enough to offer the template. Any questions just ask or pm. Thanks

I finally fixed the heater blend door in the 99 I've been working on! I'd like to thank the guys from Heater Treater first off, because they were gracious enough to send me the cutting template for the 97+ models. Without this for guidance, I wouldn't have attempted to cut into the heater box. Details and pictures below...

Long story short, I spent about 3 hours today cutting into the heater box, experimenting with fixes for what I observed to be the problem and then putting it all back together to get a working heating/cooling system again.

Summary of situation

Ok, so the hvac temperature was "kind of" working in this 99. It never got as hot as it should have, and sometimes the cold wasn't very cold either. After ruling out problems such as the thermostat and heater core, I knew this was probably the infamous blend door problem.

My motor was fine, but part of the blend door shaft was broken. I originally thought that since a section of the shaft was broken, that when it cycled on that side, it created a temporary weak point, then the door popped out of position. Ultimately, I don't think that was the issue at all. I believe that the MAIN problem was that the top shaft end of the

blend door was NOT fitting into the hole in the top of the heater box solidly. I tried to make a metal sleeve for the broken bottom shaft (old bus fuse tin made into a circle, then soldered and grinded/sanded down), but the clearance was not enough for it to fit back into the bottom shaft pivot point.

The HARDEST part of this whole job was putting the blend door back in the hole that you cut for access. You really need to get the bottom of the door in the bottom pivot point, then push the top in at an angle. It's really a nightmare procedure and my forearms are pretty tore up from wrestling with it multiple times.

Details I observed after cutting into the heater box and fix:

1. door seemed really tight. This seemed to be caused by the top and bottom flaps being taller than they needed to be. Within the heater box, the flaps were bent about 1/8 inch, that is they didn't clear the box, they were in there bent against the top and bottom. I realize this is to make a tight air seal, but I'm pretty sure it contributed to the problem in my case. I trimmed those as seen in the picture.

2. the MAIN problem with my door was that when it would be put to full cold, the actuator motor stressed, and then the top of the door would pop out of the pivot point EVERY time! I sanded the top part of the top shaft end down, and I honestly believe that this was the miracle cure. I really don't think the shaft was sitting tightly in the

hole at the top of the heater box before....it was just kind of wedged against the top and that's why the air was not going full hot or cold, but was still changing. It was working, but was not sealing completely off one way or the other.

To seal everything up, I used this black locktite tape called "sumo" that I found at walmart. It is a LOT more adhesive that duct tape, and seems very durable. Time will tell. If it doesn't hold up though I'll prob use that aluminum tape next time.

In my case, the problem is solved for now. If it fails in the future, I'll be buying the heater treater door, but I really couldn't afford the $120 right now, again, I really want to Thank the guys at heater treater for being nice enough to offer the template. Any questions just ask or pm. Thanks