redrider2911

NAXJA Forum User

- Location

- Yakima, WA

Alright so after talking to some of my customers and talking to guys on jeep forums I decided to make some changes to the crossmember that comes with the 3 link long arm upgrade I sale.

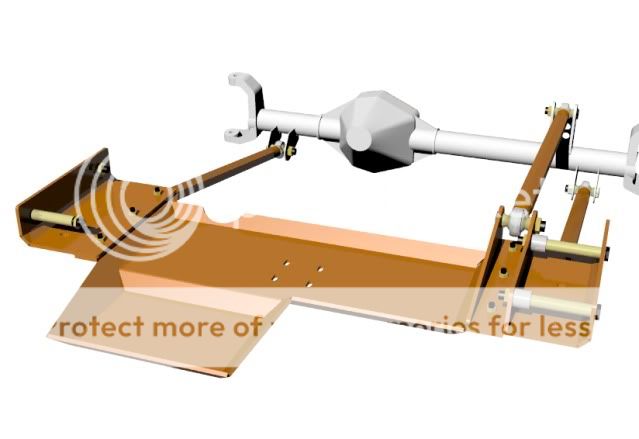

Originally it was just this. which was plenty beefy but there are a couple things i didnt like.

First, i wasnt so found of the link mounts being directly part of the crossmember. This meant in order to do any drive train work you had to block the front axle, take off the links, then drop the crossmember. Then put it all back together and align it again. Second I thought that it looked a little to blocky. Looks arent exactly everything but eh... Plus i guess it could cause you to get caught up on some ledges. Last I figured if i was going to revamp it, I might as well do it right. So I added a tcase skid as well since those things hang so far down...

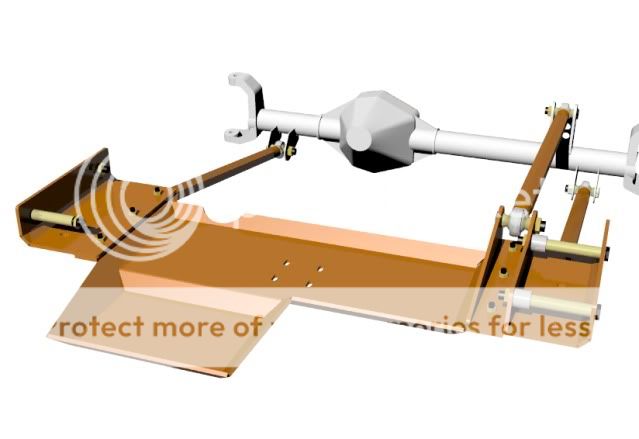

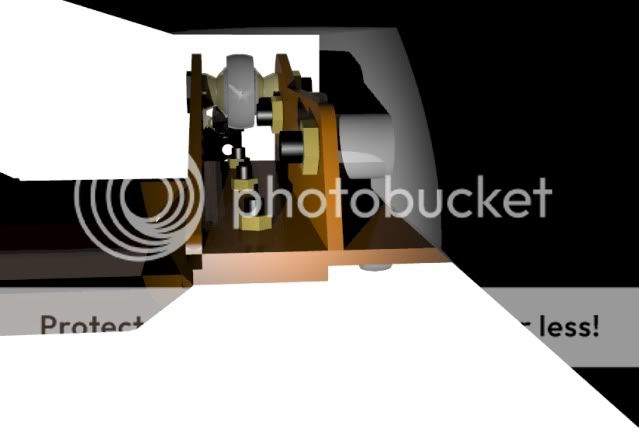

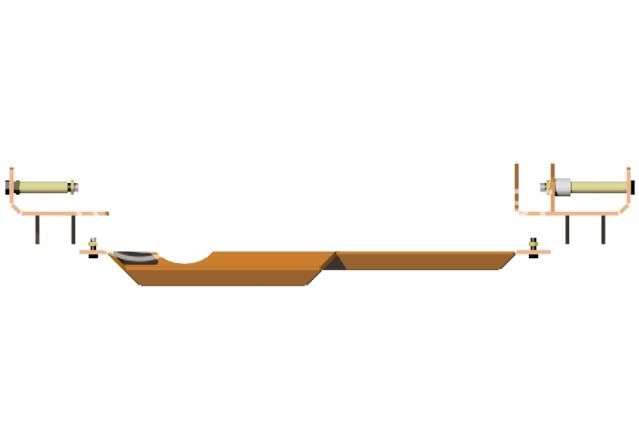

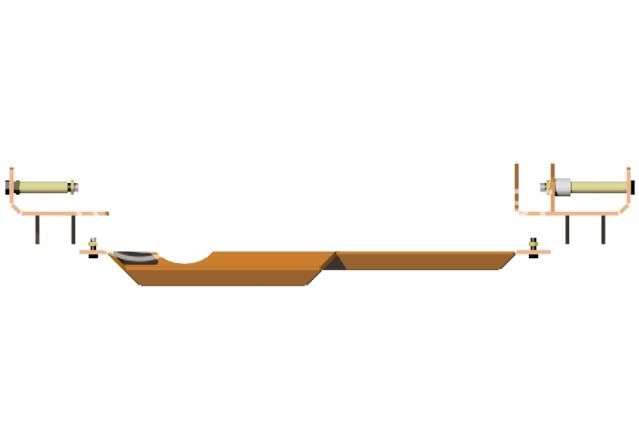

So this is what I got.

Any ideas, thoughts and concerns, or constructive criticism would be good.

Originally it was just this. which was plenty beefy but there are a couple things i didnt like.

First, i wasnt so found of the link mounts being directly part of the crossmember. This meant in order to do any drive train work you had to block the front axle, take off the links, then drop the crossmember. Then put it all back together and align it again. Second I thought that it looked a little to blocky. Looks arent exactly everything but eh... Plus i guess it could cause you to get caught up on some ledges. Last I figured if i was going to revamp it, I might as well do it right. So I added a tcase skid as well since those things hang so far down...

So this is what I got.

Any ideas, thoughts and concerns, or constructive criticism would be good.