- Location

- Roanoke VA

Okay, I have been down this road with this truck before. When I bought it 2 years ago it was sitting dead with no fuel pressure. I traced the problem to the starter relay. I got power to the pump but it still would not work. I replaced the pump with a new unit and all was good until a month ago. I have also had a issue with the bulkhead connector dropping power to the pump and radio, nothing else. You can wiggle the connector and then it would get power back and run.

Finally last Thursday it just would not start. At first I thought the CPS but I can prime the throttle body and it will fire. I have no pressure at the rail.

I started testing and tracing the problem today. I removed, checked, tightened the pins and installed some new die-electric grease in to the bulkhead connector. I see no issues there at all. I have power to the radio now along with everything else.

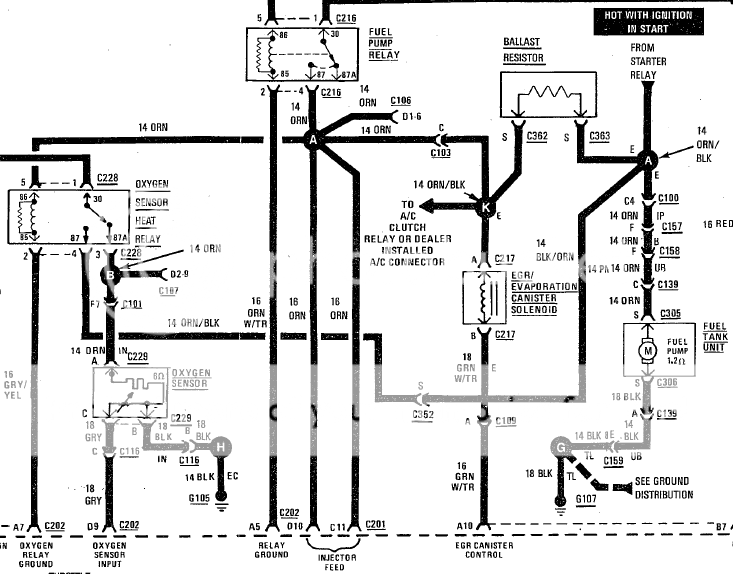

I had bypassed the ballast resistor a while back. I now do not have power there when the key is in the "run" position, I do not have power at the pump but I do have a ground. I think the issue is somewhere around the starter relay again or possibly a relay or fusible link, maybe even a ignition switch. I do not have a wire schematic for the RENIX so if someone can tell me where the power to the ballast resistor is coming from I would really appreciate it. I need to get this thing running for my son since it is his only car.

Finally last Thursday it just would not start. At first I thought the CPS but I can prime the throttle body and it will fire. I have no pressure at the rail.

I started testing and tracing the problem today. I removed, checked, tightened the pins and installed some new die-electric grease in to the bulkhead connector. I see no issues there at all. I have power to the radio now along with everything else.

I had bypassed the ballast resistor a while back. I now do not have power there when the key is in the "run" position, I do not have power at the pump but I do have a ground. I think the issue is somewhere around the starter relay again or possibly a relay or fusible link, maybe even a ignition switch. I do not have a wire schematic for the RENIX so if someone can tell me where the power to the ballast resistor is coming from I would really appreciate it. I need to get this thing running for my son since it is his only car.