Well, I have no idea where my camera is, so I borrowed my moms.

The cage is still tacked together, the interior is a mess, and it is in a general state of disarray. I still have a lot of clean up work to do to even make it look semi legit.

So this part of the build has gone on at my friend Fosters' house over the last couple of weeks. Foster has a tube bender and notcher, and has built a couple of cages before, so he had a lot more experience that I do (none).

I have been saving pictures of XJ and other cages for a long time and kind of melded them all together to basically have it look exactly like all the other cages out there. Like Ive said before, its the typical exo halo/A pillar and internal B and C pillars. I will be adding a X/seat belt bars on the B pillar, and a bit more bracing on the roof. Yes it needs more triangulation Hasta

Seat mounts. These will adventualy be tied across the tranny tunnel, we just wanted to get the seats in before doing that to avoid running a tube where the seat needed to be.

B and C pillars. Holes were drilled in the roof and the pillars go up to the spreader bars on the halo.

Both the B and C pillars are hidden behind the actually pillars of the Jeep. Im hoping it will look a lot cleaner that way.

Side shot showing the A pillar and halo. Fenders will be going back on. This section of the build most likely wont have any fender bars going on. That will happen later on down the road, unless I have time.

From the front. It looks a lot bulkier in the picture then it does in real life. We tried to get it to follow the lines of the Jeep as well as get it as tight as possible, and I think we did a dang good job at it.

Roof. This will have a bunch more X's and Y's and things up there eventually.

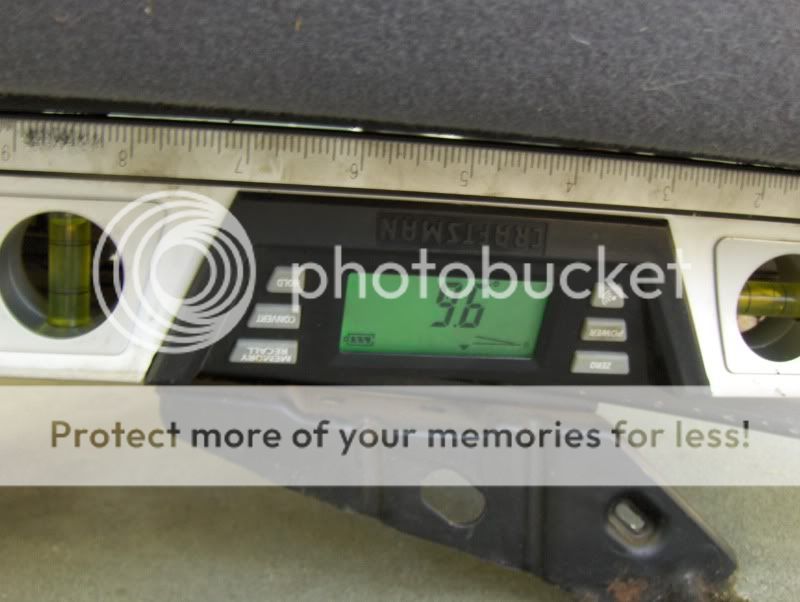

The A pillar portion of the halo has two bends in it. A 5* and a 85*. We should have done a 10* and a 80* to follow the body a bit better, but what can you do.

So thats it for the cage portion of this update. Next up Im working on seat mounts. This is some of the most tedious and worthless stuff Ive ever done. You spend hours doing small little brackets all to bolt seats down. Really?