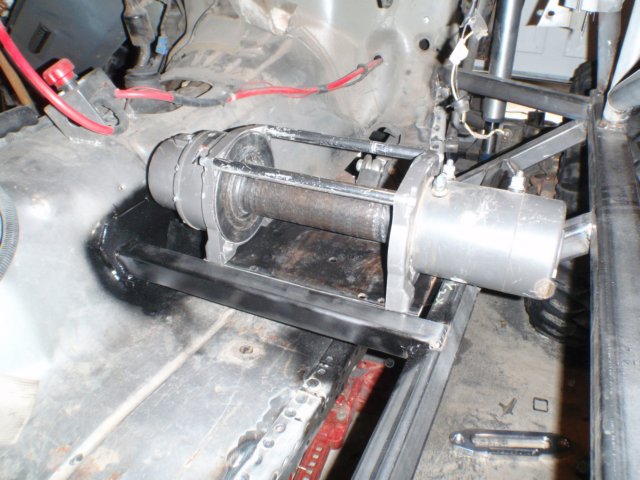

Set the winch on the plate, and moved it as far to the outside of the rig as I could, leaving ~1/4" between the 'plane' created by the boatsides - so even if I hit the skin hard, hopefully it wont damage this poor winch anymore...

and then burned it in -

of course, I forgot to check, to make sure the fairlead fits with the winch plate thing flush with the tops of the rec tube... and of course it doesnt fit...

Eli and I had joked at the swap meet about cutting excess weight off the spidertrax aluminum fairlead... well, I cut off excess weight...

not having access to a mill, lathe, or any kind of machine tools, I went to Ace Hardware and got some wood/metal blades for the sawzall, and made the fairlead fit...

Remember when cutting aluminum, the larger voids in-between teeth is importiant - the fine tooth count blades that work well with steel clog up with aluminum, and you end up ripping teeth off the blade, and eventually ripping the blade outta the sawzall... the 'Miluakee Wood with Nails' blades work decent...

The cutoff wheel works OK to start the cut, but really does a piss poor job. Perhaps one of the carbide tipped 4.5" mini sawblades that look like a horrible idea every time I see them at the hardware store would work well?

anyway, I made a hack ass cut in an otherwise really nice part... :eek2:

added a little paint -

bolted everything in -

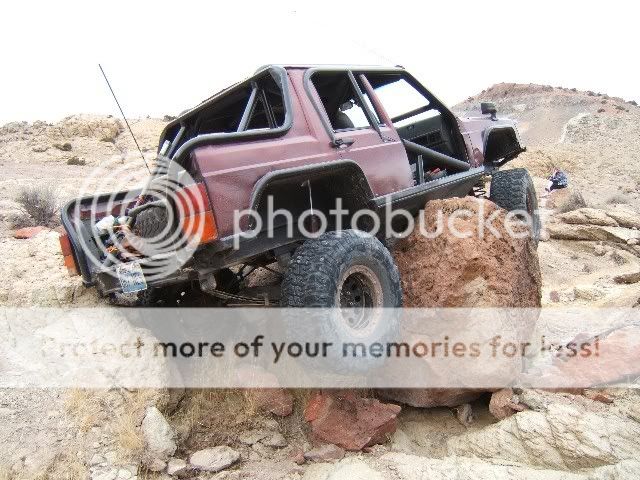

If you're wondering what is all over my seat - its gear oil... apparently when inverted, the top of my transmission leeks...