RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

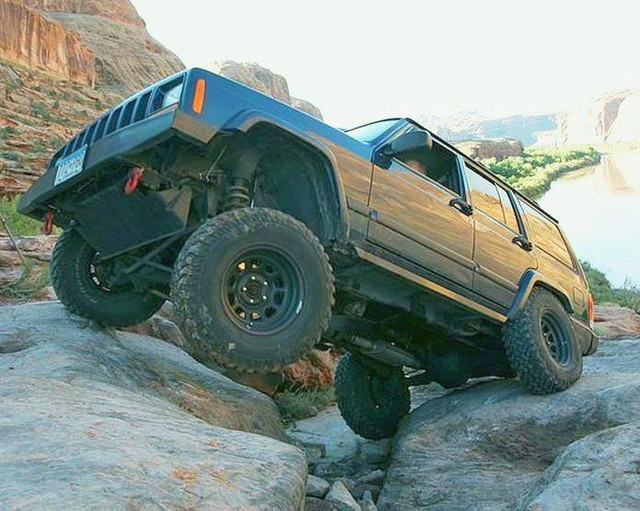

Not a very good pic but your angles look "close".

Not a very good pic but your angles look "close".

First realize that the RE 1600 trackbar is one of the worst. I've had my RE 1660, 1665, and 1670 now for over twenty years!

It looks like a heim joint bolted into the factory track bar location at frame end. If it is could be creaking be that heim is running at ride height with alot of missalignment.

Angles do look close. Youd have to use some kind of straight edge to measure angle on each to make sure they are close like they look.

Could also make noise at track bar axle end if bolt is moving in a wallowed out bolt hole.

Sent from my SM-G781U using Tapatalk

The question for me is that will it be an issue if I change it out the IRO or different drop bracket. I definitely need to fix whatever is causing the creaking.

Thanks. Here’s a better shot of the joint. The noise went away when I lubed the heim but maybe there’s something wallowed like you suggested and it’s just apparent at the joint.

...

Sent from my iPhone using Tapatalk

Thanks. That all makes sense except I don't quite understand elongating the holes. This is all new to me though so I'm sure it will make sense once I start putting it together.You can drill things out to a larger size and use larger hardware.

You can weld undersized washers (or even just steel strap) over the holes and then drill them out to the size you want them to be.

Or you can weld the track bar bracket in place.

Best route is to first plate the front frame rails then bolt and weld in a double shear track bar bracket. Just know that once you have plated the frame rails you will need to elongate a couple of the holes in order to install the track bar bolts. You want to make sure you do that. The bolts are all important, even with the welding.

That makes sense. It's probably not clear from my photos but the problem area on mine are the horizontal bolts that go through the wheel well into nuts below the air box. My plan was to have someone weld the plate or washers in the engine compartment so the bracket would still set flush.The bolts on the side of the frame are horizontal. The bolts that come in from underneath (sort of in the engine bay) are vertical. Once you add 3/16" or more of frame plating on the outside of the frame you then move the bracket that much farther outboard. Now the bolts that need to come from underneath will no longer line up. You will need to slot the holes in the bracket in order to compensate for the thickness of the frame plating.

Thanks. That's reassuring. I'm definitely replacing the bar and bracket with IRO one. The PO was pretty creative/sloppy so I'm changing hardware on everything I replace.I'm not sure that the holes in the unibody rail are actually wallowed out. Isn't that factory slotting to aid in installation?

My concern is still the janky single shear bolt holding the heim joint to the track bar bracket. That looks scary. Since you can't weld, I recommend replacing the track bar bracket with a double shear setup. You might be able to continue using the current track bar, perhaps with a new heim. You'll need to measure the mounting width of that heim.

Whether you decide to stick with your current track bar bracket or get a new one, use some new grade 8 (SAE) or grade 10.9 (metric) bolts to hold the bracket to the unibody rail.

Sounds good. I've been looking around for decent hardware but I can't find the right sized flanged nuts and bolts in 10.9 anywhere locally so I think I'll order from Fastenal unless someone has a better suggestion. They look to be 12m 1.75x40. I'd like to keep it correct as much as possible and avoid switching to SAE.Start with fresh non Chinese bolts and nuts, with proper torque. The holes are just barely worn out of round, I wouldn't get too concerned, and certainly would not start welding stuff.

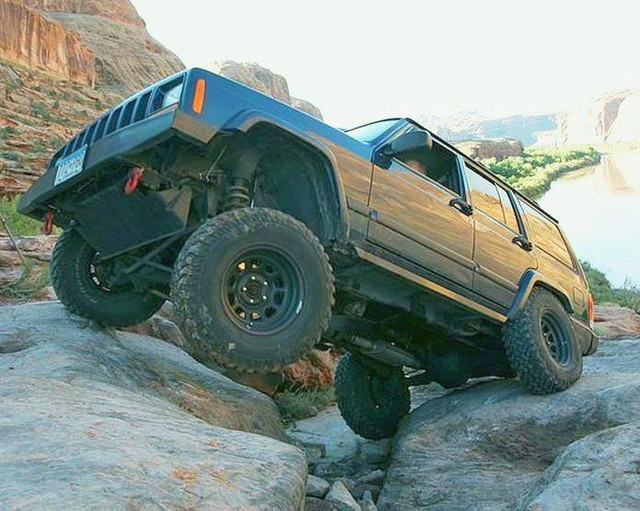

I would very strongly recommend a double shear track bar and new heavy duty frame bracket. The one from IRO works great for me. You should do some research and see if a track bar mount reinforcement to the opposite side frame rail would fit, or would be beneficial.

I do not think plating the frame rails is necessary for 3 inch lift, unless you are doing some really radical off-roading.

Here is recent picture of my IRO double shear track bar with 5.5 inches of lift and non plated frame rails.

.