90xj_zach

NAXJA Forum User

- Location

- waterloo, IL

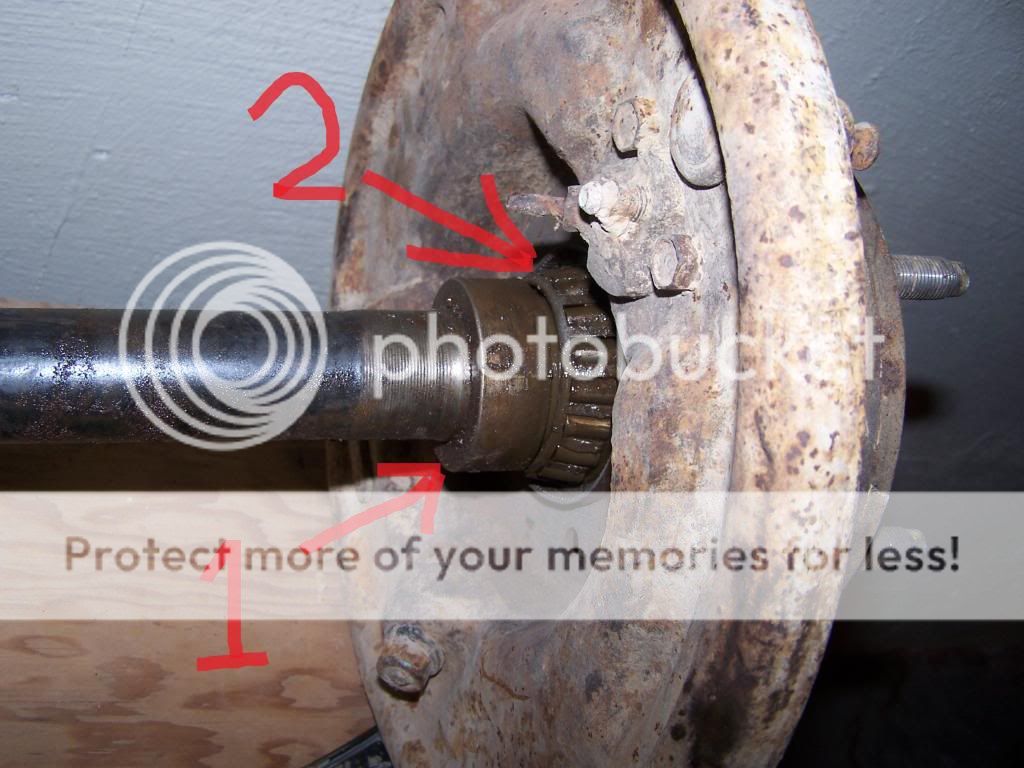

Hey guys. I just bought a HP44 out of 77 F 150 (radius arm mounts will be cut off), and a Ford 9" out of a 1979 F 150. They will need gears, spool in the rear, locker in the front. I will be converting the back to disk (already researched quite a bit on here for ideas). The front brakes are all there, but very rusty so I will need new rotors and calipers.

They will be going under my 98 xj, and will have 36" Iroks at each end. As of now I plan on utilizing the factory style 4 control arm set up (adjustables). The jeep is never on the street and will be trailered to the wheeling locations.

There is my life story. Anybody have helpful hints for the swap? I'm not a fabricating genious, but welding, and cutting metal is of no concern by the way. If any of you guys have convenient steering advice, or worth while purchases to make the job easier, I would appreciate it! I'm also a little concerned about getting the the brake lines from the Cherokee connected to the axles when that time comes.

They will be going under my 98 xj, and will have 36" Iroks at each end. As of now I plan on utilizing the factory style 4 control arm set up (adjustables). The jeep is never on the street and will be trailered to the wheeling locations.

There is my life story. Anybody have helpful hints for the swap? I'm not a fabricating genious, but welding, and cutting metal is of no concern by the way. If any of you guys have convenient steering advice, or worth while purchases to make the job easier, I would appreciate it! I'm also a little concerned about getting the the brake lines from the Cherokee connected to the axles when that time comes.