Got them in postion on the Jeep. Don't mind the electrical conduit it was all I had to get them to stay in place easy. This is with 6" of uptravel and 8" of downtravel. This leaves me with 1.5" of clearance to the "frame" and 2" of clearance to the tire. I think this should be fine?

Ran into a issue with the hatch clearance.

So...

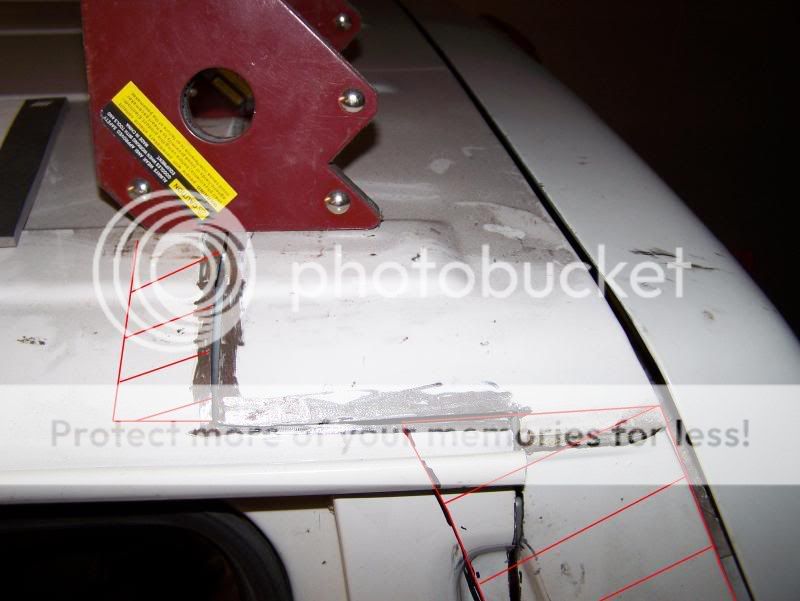

After all the work getting the rear 'D' pillar moved forward, it is going to disappear. The below to pictures show what I'm going to cut out and remove (red hatched sections). I'll be sliding the top section of roof forward (see second picture) This should gain me 3.5" and plenty of room for the coilover.

That is it for tonight. Gonna sit down with some Eggnog and rum and hit the hay early so I can get a good start tomorrow before I have to quit early.