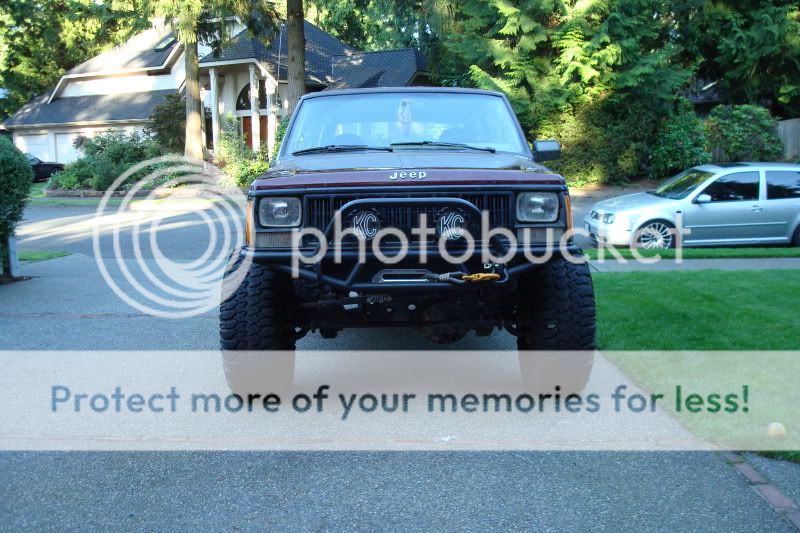

Well I haven't had a whole lot of time to get the front tubes done, but I did make some progress. All that is left is to weld in the tube for the radio antenna clearance hole, mount the tube flanges, clean up the paint from the to be welded areas, burn everything home and re-paint it. The tube flanges (only just sitting on the driver's side) are there solely so if I have to remove the bumper I can. I don't like the looks of them but I'm not paying the big bucks for some of the fancy ones, nor do I feel like making them so these will have to do.

Here's how I'll be able to keep the antenna. I just cut a hole for some 1.5" 0.250 wall (all I had kicking around) and this will allow the antenna to come up through the tube. Those of you that know me know it'll probably never get used as I never listen to anything from the speakers, but hey this was easier than patching a hole in the fender if I removed it completely. I'll weld it in, and smooth it out and hopefully it'll be almost "hidden" with the antenna poking through.

Here's how I'll be able to keep the antenna. I just cut a hole for some 1.5" 0.250 wall (all I had kicking around) and this will allow the antenna to come up through the tube. Those of you that know me know it'll probably never get used as I never listen to anything from the speakers, but hey this was easier than patching a hole in the fender if I removed it completely. I'll weld it in, and smooth it out and hopefully it'll be almost "hidden" with the antenna poking through.