riverfever

NAXJA Forum User

- Location

- Woodland Park, Colorado

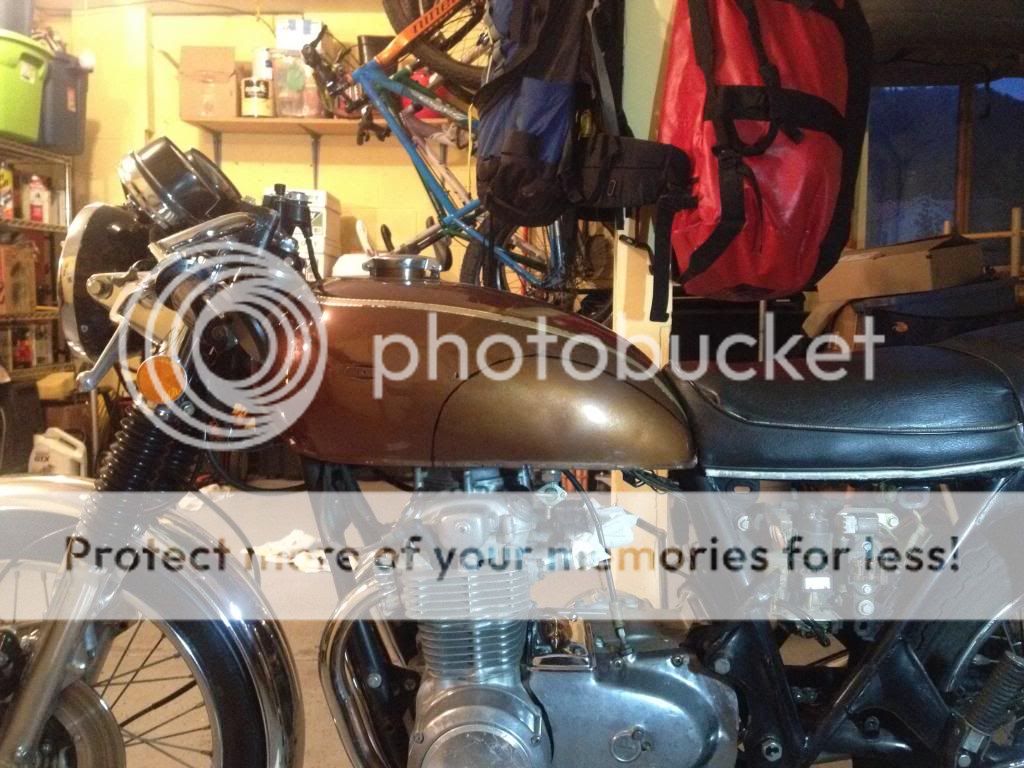

Got around to pulling the carbs the other night.

I found a few broken pieces while taking the carbs apart. This is one of them. From what I can tell, this seems to be a washer of sorts that makes sure that the needles from carbs 1 and 2 and 3 and 4 are all working in sync. It's no longer available but I'm thinking I'll be able to make a replacement from some thin metal and lot's of filing. A guy that I know who owns a shop in St. Louis said I would have to look for replacement carbs because of this piece but I find that very hard to believe. We'll see.

This is another broken part. This appears to be a dust seal of sorts. Two of these are situated in the linkage between 1 and 2 and 3 and 4. My idea for this was to use an old inner tube and recreate this. I'll double it up and then wrap it in Duct tape to make it stronger. Again...we'll see.

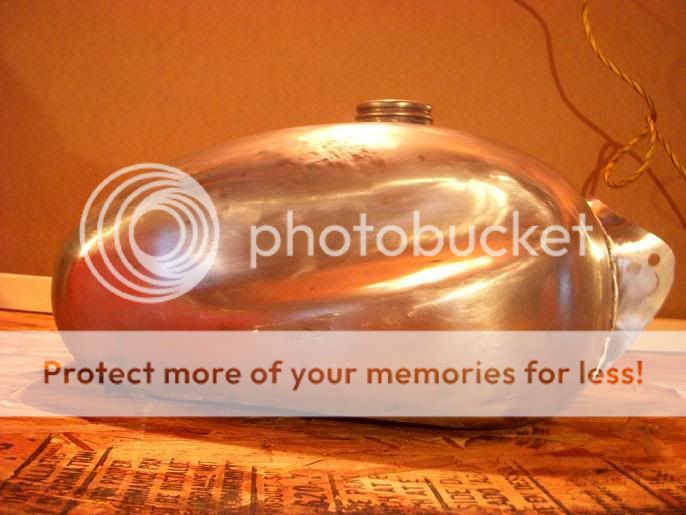

This is the bowl on the first carb I took apart. I did remove the brass valve seat guide. Tonight I bought some Berryman's Chem Dip and the carb body is currently soaking in it. I'll use compressed air to clean the passages. Not sure how else to make sure that everything is squeaky clean. Open to suggestions.

I found a few broken pieces while taking the carbs apart. This is one of them. From what I can tell, this seems to be a washer of sorts that makes sure that the needles from carbs 1 and 2 and 3 and 4 are all working in sync. It's no longer available but I'm thinking I'll be able to make a replacement from some thin metal and lot's of filing. A guy that I know who owns a shop in St. Louis said I would have to look for replacement carbs because of this piece but I find that very hard to believe. We'll see.

This is another broken part. This appears to be a dust seal of sorts. Two of these are situated in the linkage between 1 and 2 and 3 and 4. My idea for this was to use an old inner tube and recreate this. I'll double it up and then wrap it in Duct tape to make it stronger. Again...we'll see.

This is the bowl on the first carb I took apart. I did remove the brass valve seat guide. Tonight I bought some Berryman's Chem Dip and the carb body is currently soaking in it. I'll use compressed air to clean the passages. Not sure how else to make sure that everything is squeaky clean. Open to suggestions.