riverfever

NAXJA Forum User

- Location

- Woodland Park, Colorado

I think there's a little bit of an artist mixed in with your wrenching skills.

Sent from my SM-N920P using Tapatalk

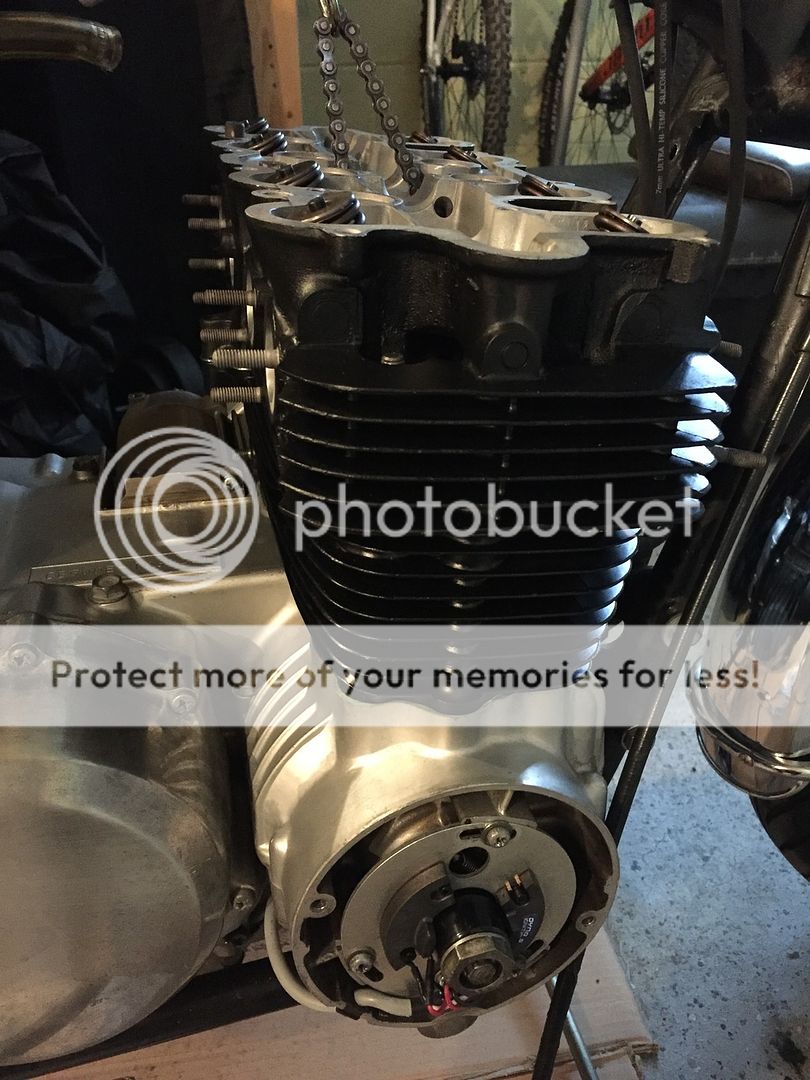

Thanks Steve. I have this vision in my head of how this thing is going to turn out and, unfortunately, I see this build going in two stages. The first one will end with the frame being painted or powder coated and the tank and side covers getting painted as well. I also plan on doing some more polishing and a major upgrade to the electrical system. If 2.0 happens it will include custom wheels and a modern front end which will take a while to collect the parts but I'll be able to ride it while I'm doing that.