redrider2911

NAXJA Forum User

- Location

- Yakima, WA

I have been building custom lifts for friends and other customers in the area ever since I was a junior in highschool. This is my latest build for a customer in Yakima. Alright. So first I would like to state a couple of complications me and this customer, Jeff ran into. Originally the plan was to use the stock front axle with the disco. Because of this I designed the crossmember with the uca mount close as possible to the tranny on the passenger side in order to keep the uca as parallel as possible while avoiding the disco hardware. Because of this, the exhaust needs to be rerouted and I couldn't use my normal means of the axle side track bar mount. The following pictures will help explain.

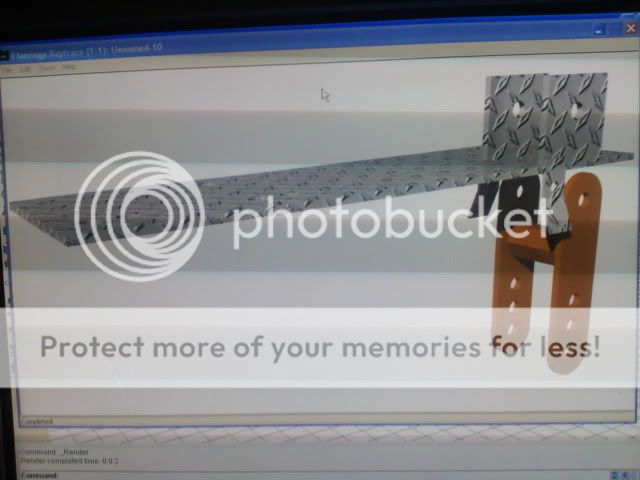

Drew this up later in autocad and laser cut it, on to the press break for bending, then welded up on the bench.

These are my original 3d designs we used to mockup the new suspension setup. We also decided to build a 1 inch drop into the crossmember because Jeff didnt feel the extra money for a sye was not worth it right now.

The lca mounts are barely below the frame rail because in order to raise them the uca mount would come through the floor and this is a daily driver so it was not an option although he did not really lose any needed clearance.

The crossmember complete and bolted up. You can see where the uca mount is pushed over to the drivers side. After I designed and built the crossmember Jeff finally dropped a little money and decided to pick up a non disco d30. Because of the change in plans we still welded the uca mount in the planned place on the axle and fabbed up a more unconvential track bar mount off the coil perch that you can see a little of in this picture.

This is how I normally mount up my uca and track bar using the same mount welded right next to the coil perch.

This next picture is just a fun picture. the ground thawed and refroze so we literally had to chain it up and get a run at it with another jeep to pull it out. :idea: You can see one of the lca's there. I use 1 1/4 solid stock stress proof hex to give it a unique look and great strength. The heims are 7/8s chromoly with high misalignment spacers purchased from ruffstuff.

A view from the side before tires.

A little underneath. Need to cut off the stock lca mounts.

K. Now for the steering. drilled out the knuckles and pitman arm to 5/8s and used 3/4 heims with misalighment spacers.

No need for spacers on the tie rod so I purchased 3/4 to 5/8 bushings found at any local hardware store.

I chose to run the tie rod itself under the knuckle for better draglink-track bar geometry. The tie rod is still well above center axle and shouldn't be an issue with clearance or rocks. I have landed on my tie rod pretty hard a couple times and this material doesnt bend!

Here's a side shot of the whole setup working together.

Drew this up later in autocad and laser cut it, on to the press break for bending, then welded up on the bench.

These are my original 3d designs we used to mockup the new suspension setup. We also decided to build a 1 inch drop into the crossmember because Jeff didnt feel the extra money for a sye was not worth it right now.

The lca mounts are barely below the frame rail because in order to raise them the uca mount would come through the floor and this is a daily driver so it was not an option although he did not really lose any needed clearance.

The crossmember complete and bolted up. You can see where the uca mount is pushed over to the drivers side. After I designed and built the crossmember Jeff finally dropped a little money and decided to pick up a non disco d30. Because of the change in plans we still welded the uca mount in the planned place on the axle and fabbed up a more unconvential track bar mount off the coil perch that you can see a little of in this picture.

This is how I normally mount up my uca and track bar using the same mount welded right next to the coil perch.

This next picture is just a fun picture. the ground thawed and refroze so we literally had to chain it up and get a run at it with another jeep to pull it out. :idea: You can see one of the lca's there. I use 1 1/4 solid stock stress proof hex to give it a unique look and great strength. The heims are 7/8s chromoly with high misalignment spacers purchased from ruffstuff.

A view from the side before tires.

A little underneath. Need to cut off the stock lca mounts.

K. Now for the steering. drilled out the knuckles and pitman arm to 5/8s and used 3/4 heims with misalighment spacers.

No need for spacers on the tie rod so I purchased 3/4 to 5/8 bushings found at any local hardware store.

I chose to run the tie rod itself under the knuckle for better draglink-track bar geometry. The tie rod is still well above center axle and shouldn't be an issue with clearance or rocks. I have landed on my tie rod pretty hard a couple times and this material doesnt bend!

Here's a side shot of the whole setup working together.