JohnX

Sarge

- Location

- Williams AZ

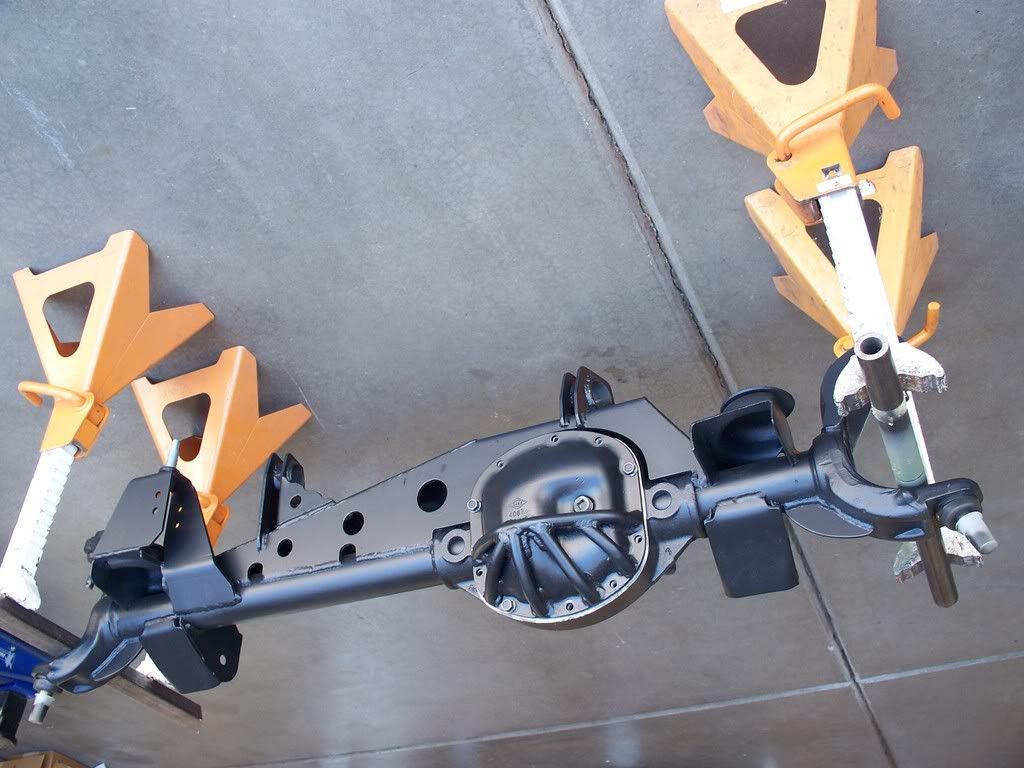

Jay I did a very light truss over the top of my 30. I made it parallel to the face of the cover, flush with the face. Then I welded a small piece onto my cover plate that sticks up about an inch over the housing. I did NOT weld to the case, only to the tubes. Then I bolted the cover on AND bolted it to the truss with four bolts over the top. Effectively I connected the case to the truss without having to worry about welding different materials. Wish I had some pics for you, maybe i'll snap some this week.