TRAILREADYXJ

NAXJA Forum User

- Location

- Woodland Park, Colorado

To start, I have had several inquiries about my rear spring setup, so I’ve decided to put it all in one place, as well as add some general shackle info. This is only for the rear, and I recommend quality lift parts in the front.

Since I first lifted my XJ, I have used some form of “bastard pack” in the rear. I started with a 2” BB that grew into 3”, then 4.5”… I always had great success going this route, and at 2-3.5” the ride was great. At 4.5” it wasn’t bad, but I felt there was room for improvement.

The problems:

Aside from the fact that by adding leaves that are stiffer or higher arched, your shackle angle had a HUGE impact on how the pack will perform! By adding more arch to the XJ main, the eyes are pulled closer together, causing the shackle angle to get worse. Once you get to the point the shackle is pointing forward at ride height, it has to fight itself and the weight of the Jeep when the spring compresses. This also severely limits droop, as the shackle is already in the “ideal drooped position”.

Another issue is in the stock shackle mount itself. With the way it’s designed there is not a whole lot of travel, and getting an ideal shackle angle is impossible without use of a boomerang shackle. Ideally you want the shackle to sit about 45* toward the rear at ride height. Without a boomerang, the shackle hits the rear cross member too soon. A boomerang shackle will increase travel, however they will do NOTHING to correct the shackle angle.

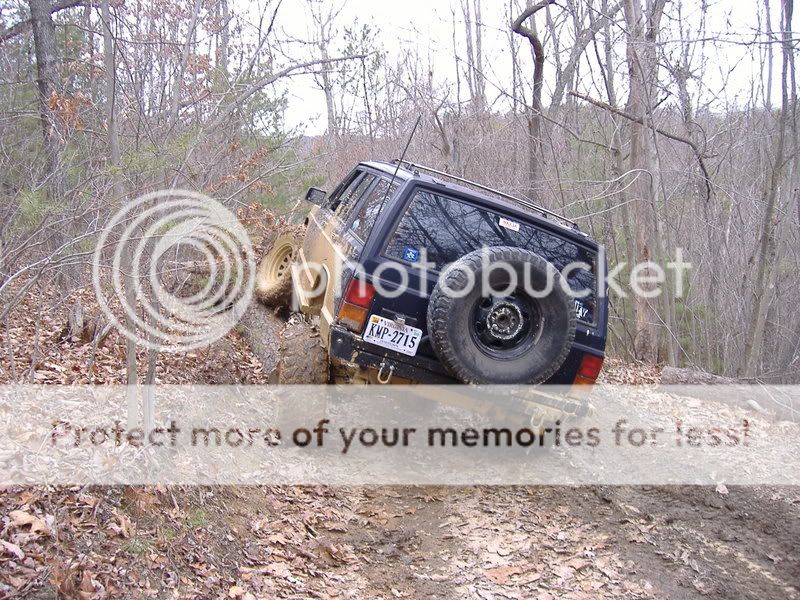

Here is an example of the limited travel allowed by the stock mount using a regular drop shackle.

Solutions:

Several members here have made relocation mounts for the shackles. This can be done on any setup to improve the ride and flex! The general idea is to relocate the mount to improve the shackle angle, as well as free up travel. Another benefit is this gives lift, allowing for a flatter leaf pack. As a general rule, the flatter the pack, the better it will perform. Here is another thread with relocation mounts http://www.naxja.org/forum/showthread.php?t=943105

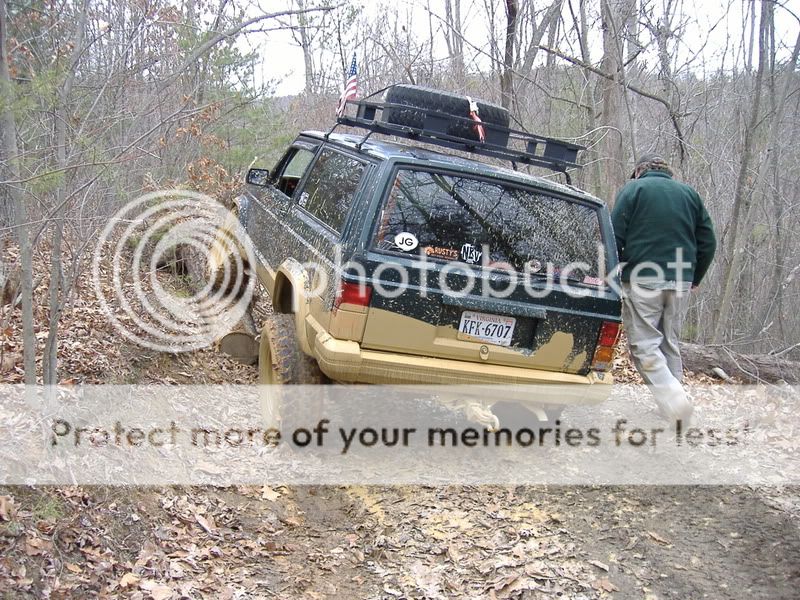

Here are some mounts I made for a friends build. He is running “bastardized” RC spring packs and RC shackles. This thing will be at about 8”, but this can be used with smaller lifts as well.

Here is the top mount that slides into the factory pocket (very unfinished in this pic)

Mounted:

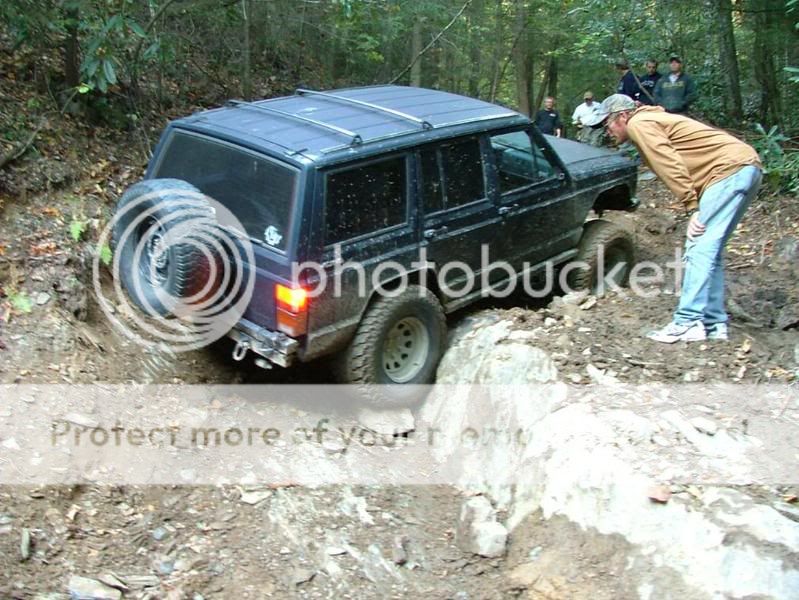

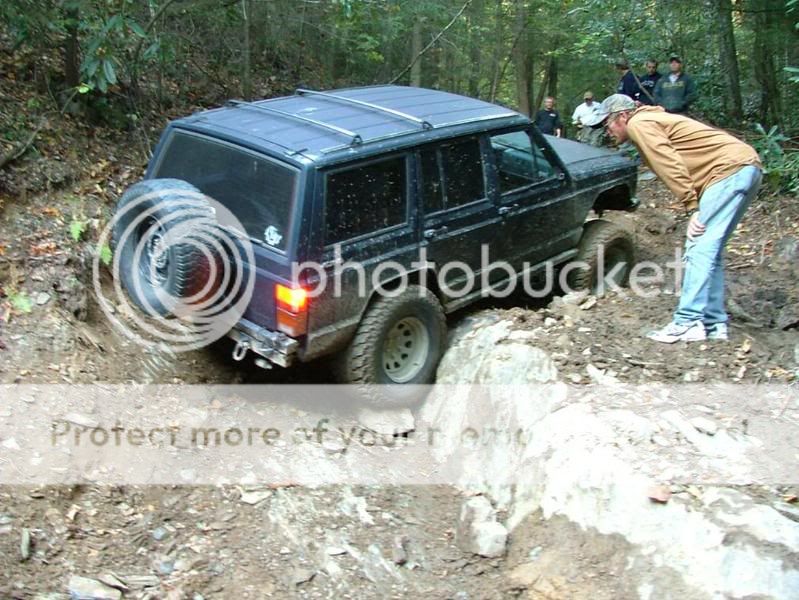

The only real negatives I have found with this setup is the simple fact the rear springs hang down lower. I have dragged mine over rocks a lot, but it has never caused any issues or snags. I wouldn’t recommend this for lifts smaller than 4.5” though.

Now for the F-150 part:

As I mentioned earlier, a flatter spring pack will ride better. In addition, the longer the pack is, less arch is needed to achieve a given amount of lift. Toyota guys often swap 63” Chevy springs in for this very reason.

I happened to have some spring packs from a F-150 I used to build bastards out of. After some comparison, I found these may be perfect for my goals. They are probably from an 80s to early 90s truck, definitely pre-97 as they are different from my 97 F-150. The packs have 4 leaves including the main, plus an overload.

The only negative is the bushings are smaller, and do not allow as much flex before the spring starts to bend. I was somewhat concerned by this, however my XJ pretty much a trail only rig so I gave it a shot. I have ran this setup for a couple years now, and aside from a small axle wrap issue (explained later), I haven’t had any problems.

I can not remember the exact measurements, but the F-150 main was about 5” longer overall, with about a 2” difference in the centering pin location.

I had the centering pin part down from the start. The spring perches on my 8.25 have 3 holes, 1 round, 2 square. I simply drilled the rear hole to fit the larger F-150 centering pin, and the spring plate to match. You may need degree shims to set the pinion angle, and these will also need to be drilled with an offset hole.

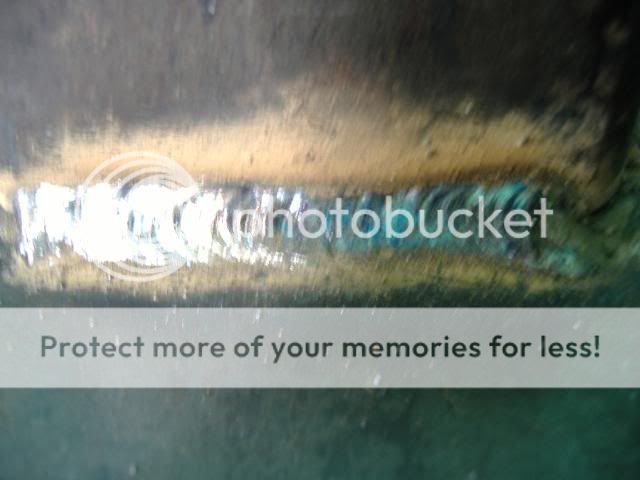

Not the best pic...

This placed the wheel about ½” further back than stock, but that was fine with me and worked with my current driveshaft. I may get flamed for this, but I am running the stock driveshaft :shock: . Believe it or not, at 5.5” I have NO vibes! I am running a 8.25 with a D35 driveshaft, YJ yoke, and T-case drop. I also made my degree shims to set the pinion angle perfect, so this may not be for everyone. Anyway…

Now something had to be done in the rear. I built a new mount to relocate the shackle. I made the one pictured earlier a bolt on, but I made mine different, and it’s bolted and welded in. It’s also obvious the shackle mount is further back to accommodate the longer spring.

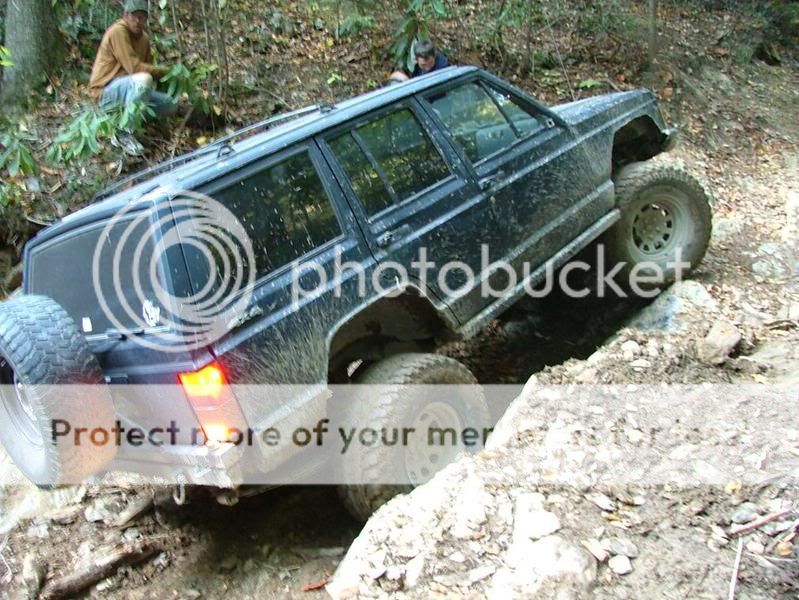

Initially, my spring pack was made from 5 leaves total. I added an extra F-150 leaf to it and removed the overload. This gave me about 6.5” or so, but I decided that was just too much, and I removed the extra spring to get 5-5.5”. I ran it this way for several months, and loved the ride and flex! It matched the front very well (Rusty’s 4.5” springs + spacer).

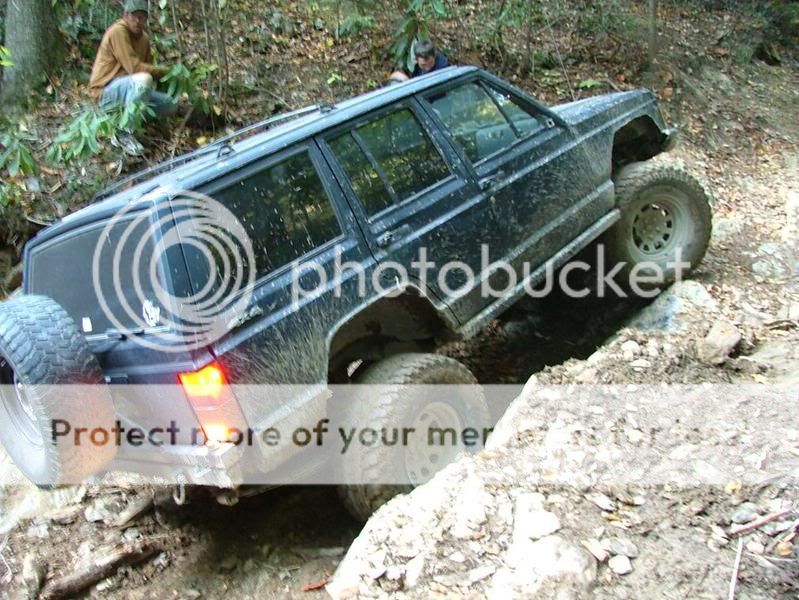

Now for my axle wrap issue… I ended up warping a spring pretty good at Callalantee last summer. Granted I wasn’t being gentle at the time, I felt ½ ton springs wouldn’t be much of a problem….wrong.

The problem is in removing the overload. Originally it helps fight axle wrap, but it also gets in the way off-road, and tends to scoop stuff up with it. I haven’t had time to build new packs, and just threw another set of stock f-150 springs in for now, but I have a solution for this problem. The F-150 leaves are rather long, and it doesn’t have the shorter leaves to fight the wrap. To maintain my ride height, I plan on removing a f-150 leaf, and adding a couple XJ leaves, staggering them evenly. More to come on that one…

Since I first lifted my XJ, I have used some form of “bastard pack” in the rear. I started with a 2” BB that grew into 3”, then 4.5”… I always had great success going this route, and at 2-3.5” the ride was great. At 4.5” it wasn’t bad, but I felt there was room for improvement.

The problems:

Aside from the fact that by adding leaves that are stiffer or higher arched, your shackle angle had a HUGE impact on how the pack will perform! By adding more arch to the XJ main, the eyes are pulled closer together, causing the shackle angle to get worse. Once you get to the point the shackle is pointing forward at ride height, it has to fight itself and the weight of the Jeep when the spring compresses. This also severely limits droop, as the shackle is already in the “ideal drooped position”.

Another issue is in the stock shackle mount itself. With the way it’s designed there is not a whole lot of travel, and getting an ideal shackle angle is impossible without use of a boomerang shackle. Ideally you want the shackle to sit about 45* toward the rear at ride height. Without a boomerang, the shackle hits the rear cross member too soon. A boomerang shackle will increase travel, however they will do NOTHING to correct the shackle angle.

Here is an example of the limited travel allowed by the stock mount using a regular drop shackle.

Solutions:

Several members here have made relocation mounts for the shackles. This can be done on any setup to improve the ride and flex! The general idea is to relocate the mount to improve the shackle angle, as well as free up travel. Another benefit is this gives lift, allowing for a flatter leaf pack. As a general rule, the flatter the pack, the better it will perform. Here is another thread with relocation mounts http://www.naxja.org/forum/showthread.php?t=943105

Here are some mounts I made for a friends build. He is running “bastardized” RC spring packs and RC shackles. This thing will be at about 8”, but this can be used with smaller lifts as well.

Here is the top mount that slides into the factory pocket (very unfinished in this pic)

Mounted:

The only real negatives I have found with this setup is the simple fact the rear springs hang down lower. I have dragged mine over rocks a lot, but it has never caused any issues or snags. I wouldn’t recommend this for lifts smaller than 4.5” though.

Now for the F-150 part:

As I mentioned earlier, a flatter spring pack will ride better. In addition, the longer the pack is, less arch is needed to achieve a given amount of lift. Toyota guys often swap 63” Chevy springs in for this very reason.

I happened to have some spring packs from a F-150 I used to build bastards out of. After some comparison, I found these may be perfect for my goals. They are probably from an 80s to early 90s truck, definitely pre-97 as they are different from my 97 F-150. The packs have 4 leaves including the main, plus an overload.

The only negative is the bushings are smaller, and do not allow as much flex before the spring starts to bend. I was somewhat concerned by this, however my XJ pretty much a trail only rig so I gave it a shot. I have ran this setup for a couple years now, and aside from a small axle wrap issue (explained later), I haven’t had any problems.

I can not remember the exact measurements, but the F-150 main was about 5” longer overall, with about a 2” difference in the centering pin location.

I had the centering pin part down from the start. The spring perches on my 8.25 have 3 holes, 1 round, 2 square. I simply drilled the rear hole to fit the larger F-150 centering pin, and the spring plate to match. You may need degree shims to set the pinion angle, and these will also need to be drilled with an offset hole.

Not the best pic...

This placed the wheel about ½” further back than stock, but that was fine with me and worked with my current driveshaft. I may get flamed for this, but I am running the stock driveshaft :shock: . Believe it or not, at 5.5” I have NO vibes! I am running a 8.25 with a D35 driveshaft, YJ yoke, and T-case drop. I also made my degree shims to set the pinion angle perfect, so this may not be for everyone. Anyway…

Now something had to be done in the rear. I built a new mount to relocate the shackle. I made the one pictured earlier a bolt on, but I made mine different, and it’s bolted and welded in. It’s also obvious the shackle mount is further back to accommodate the longer spring.

Initially, my spring pack was made from 5 leaves total. I added an extra F-150 leaf to it and removed the overload. This gave me about 6.5” or so, but I decided that was just too much, and I removed the extra spring to get 5-5.5”. I ran it this way for several months, and loved the ride and flex! It matched the front very well (Rusty’s 4.5” springs + spacer).

Now for my axle wrap issue… I ended up warping a spring pretty good at Callalantee last summer. Granted I wasn’t being gentle at the time, I felt ½ ton springs wouldn’t be much of a problem….wrong.

The problem is in removing the overload. Originally it helps fight axle wrap, but it also gets in the way off-road, and tends to scoop stuff up with it. I haven’t had time to build new packs, and just threw another set of stock f-150 springs in for now, but I have a solution for this problem. The F-150 leaves are rather long, and it doesn’t have the shorter leaves to fight the wrap. To maintain my ride height, I plan on removing a f-150 leaf, and adding a couple XJ leaves, staggering them evenly. More to come on that one…

Last edited: