Last time I posted I was slowly dialing in the little things, and trying to get the Nail Salon ready for some winter snow runs. We did get the NWC crew together at the end of December for a "Noob Snow Run", and even then the snow was pretty pathetic. I left the Jeep packed, ready for the next snow fall, only for it never to come. Worst winter, ever!

BPB and I took a little road trip down to

King of the Hammers year. It was a total blast, and really gave me the itch to race. Didn't help motivate me to work on my junk though, so most of my time has been spent nerding out on the 4500 MJ.

However, an NWC tradition

TORXfest was just around the corner, which meant I had to jump the Jeep and retrieve it out of the weeds to get it prepped for some wheeling!

TORXfest at TSF was really enjoyable. Great weather, wheeling, and people. The Nail Salon did great all day, no wrenches turned. Still getting use to how it feels as this was only the third trip out, but I'm really liking it.

I did hit the scales on the way home just out of curiosity. This is with a half tank, but also loaded with camping gear so I'd say it's pretty close to it's current trail weight. I'm pretty okay with the weight as it's still under 5K. I still have a fair bit of metal to add though.

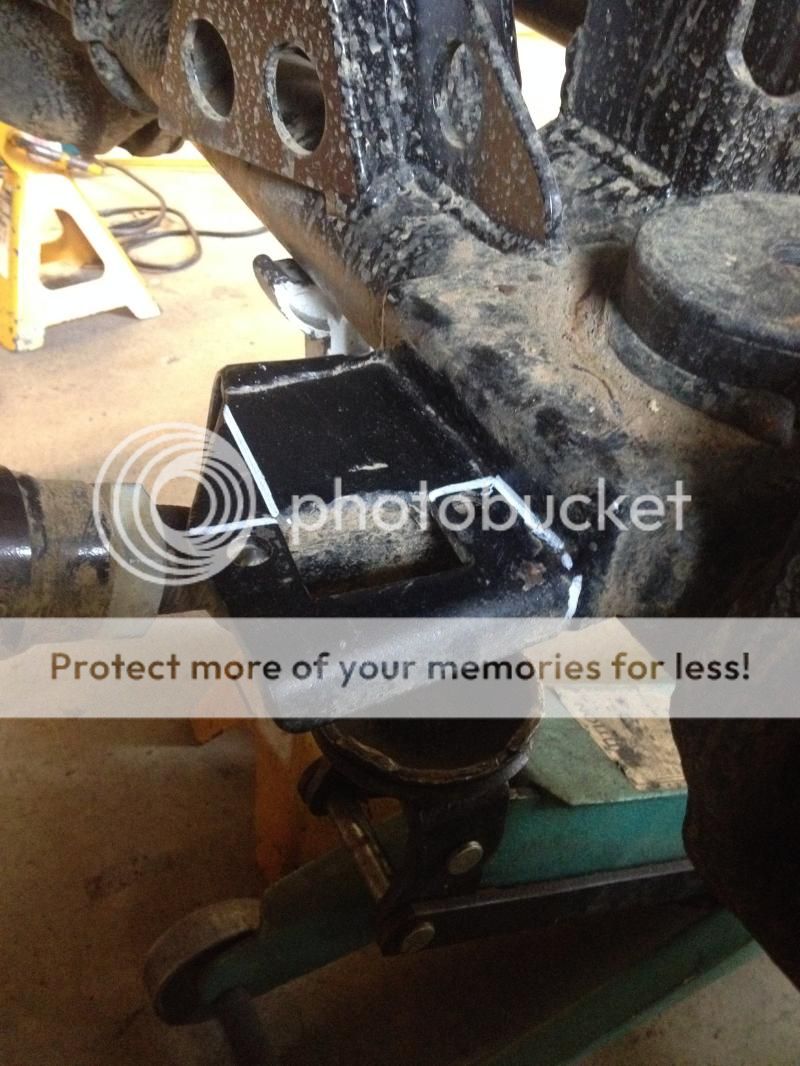

Feeling motivated after a good trip out, I decided to move forward with getting my winch mounted back up. I ditched my old winch bumper after I added the front stiffeners, which meant we were starting from scratch.

After making a few traditional winch bumpers in the past, I wanted to try a new design for a better approach angle. This would involve mounting the winch behind the front cross-member. I tried mocking up my Warn 9.5XP, only to find out it's too wide to fit between the steering box and frame due to the larger motor used. This is a case where bigger is not necessarily better.

I decided to take my winch apart to see what could be done. Remove the two allen bolts from the aluminum tie-rods, and the winch will come apart.

To remove the drum brake, push it out from the hub side. When it emerges from the drum, place a hose clamp around the brake to prevent the internal spring from unraveling. Once the clamp is on, you can remove it the rest of the way.

After a lot of pondering and brain storming, I decided to cut a section out of my perfectly good winch drum, rendering my winch useless. To be more clear I cut out 1.5" off the gear side* of the drum to bring my 9.5XP down to the more traditional M8000 width (I'll have a shorter drum though). At this point I was committed.

I chucked up each end on the lathe, faced up the cuts, and beveled the outside edge.

With the ends ready to be welded back together, I then worked on maching an internal splice connection. This would ensure both sides went back together square, and provide extra strength at the splice. I picked up some 2.5x.250" DOM to machine down to the ID of the winch drum.