DanMan2k06

NAXJA Forum User

- Location

- Damascus, MD

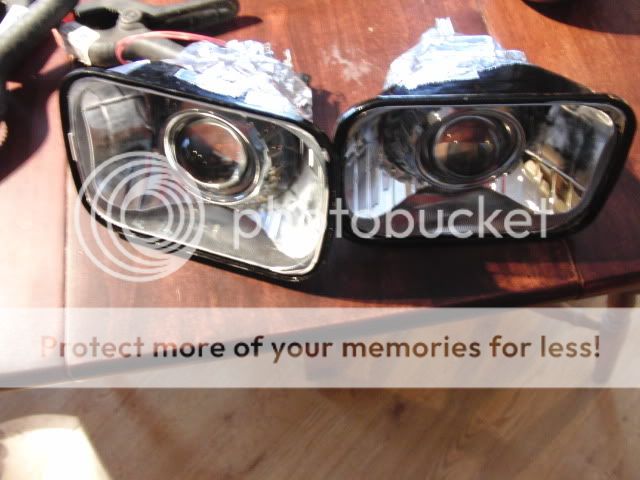

After literally years of contemplating, researching, sourcing, and gathering parts, I'm finally ready to start this project. I received all my parts in the mail, and will be tearing into things this weekend.

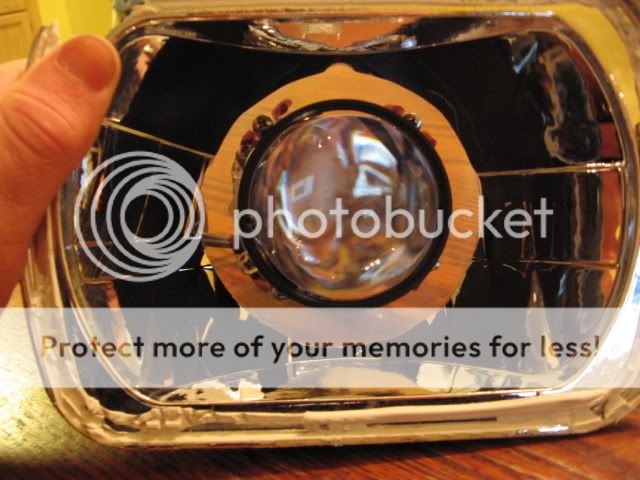

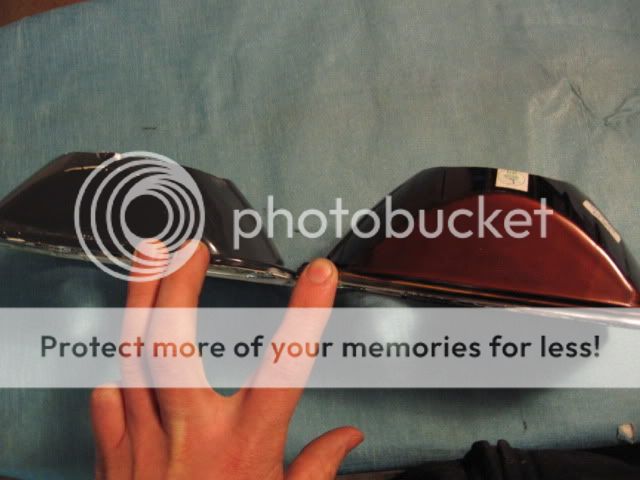

My original plan was to find a set of LS430 projectors (single xenon) and stuff them into some 7x6 housings. Then I actually DID score a set, and sonofabitch they were WAYYY too big. I would have to do some serious cutting not only to the header panels/rad support, but the projector as well. These have the AFS options, so there's a lot of moldings for the motor and such in the projector. It just wasn't going to happen.

Then I started looking for a cheap way out. Cibie housings with a kit? Or maybe some pre-made suvlight style housings? The pre-made housings were out of control expensive, and I just couldn't get myself to stick a kit inside a halogen housing... I'd be going against so many posts where I've bashed/flamed/laughed at other with it, or preached projectors are the way to go. I also REALLY wanted to keep my high beams. Bi-xenon projectors would be ideal, but I wasn't a huge fan of the FX's or e46's, and most others are just too damn big.

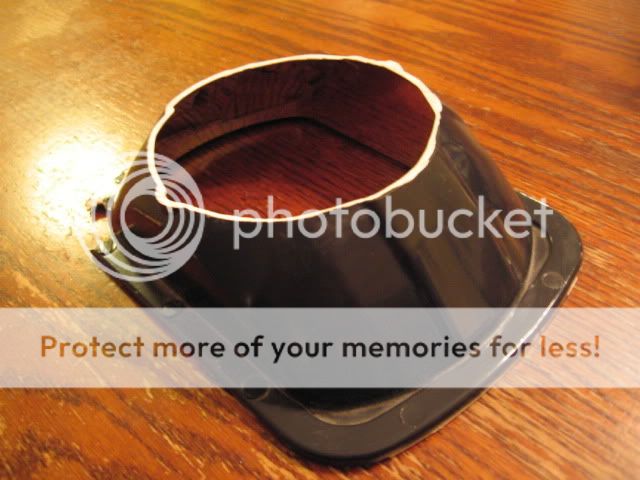

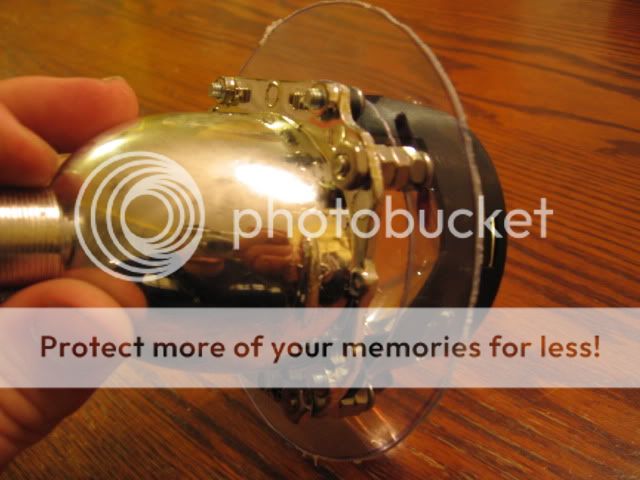

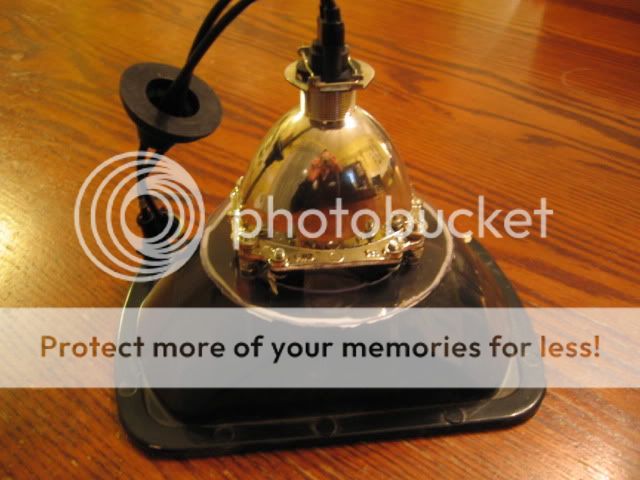

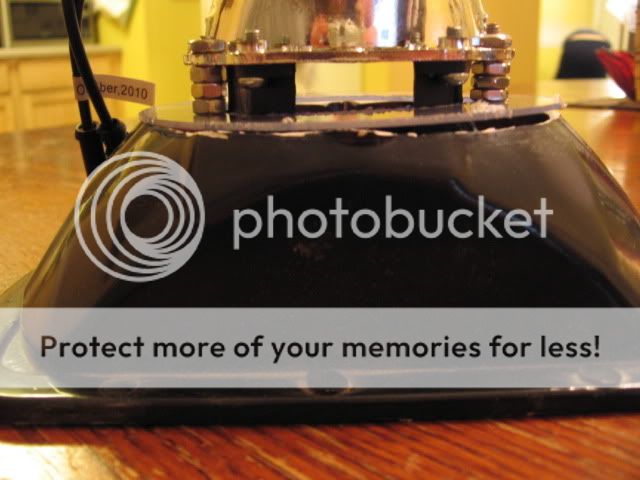

Finally, I found a solution. This wasn't around when I first started looking into a retrofit, and I'm glad someone started making something decent. They're made by a company called Morimoto (japanese I presume), and simply called the "Mini's". They are hands down the smallest bi-xenon projector on the market, and are realatively cheap and readily available.

My parts list is as follows:

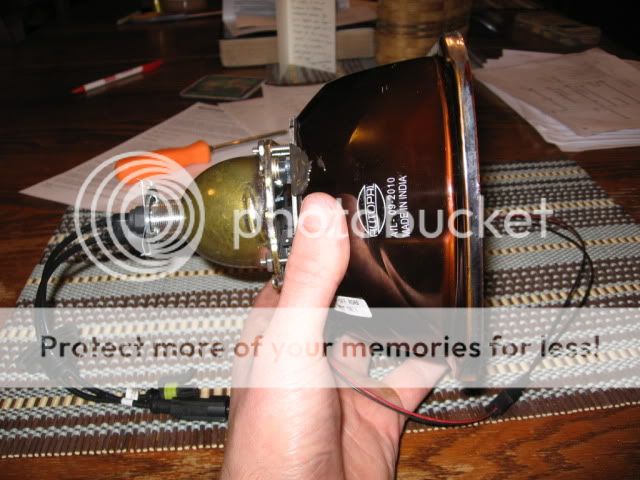

-Morimoto Mini's $120 from TRS retrofitsource.com

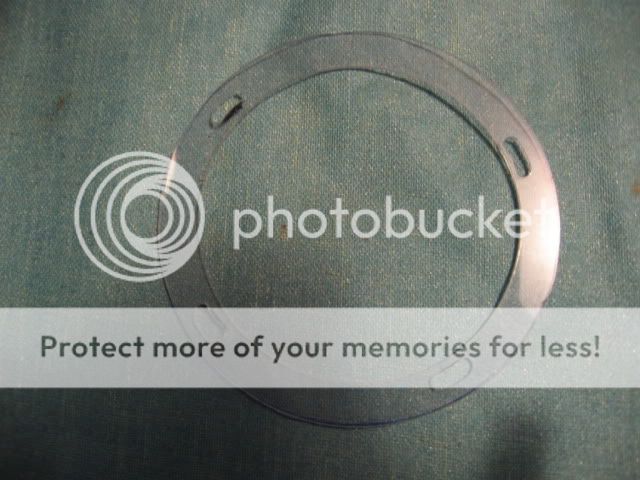

-Gattling gun shrouds $25 same as above

-E46 extended shrouds $15 'economy' option, same source

-Toyota Denso Ballasts free from work

-Philips Ultinon HID H1 bulbs $150 from ebay

-DDM chiwanese H1 HID kit $35 from ddmtuning.com

The phillips bulbs haven't arrived yet, so I ordered the ddm kit to help me with installation until the new ones come in. On TRS's website they distinclty say 'warranty is void if used with ddm style or other cheap aftermarket kits'. So I'm certainly not trying to use the DDM kit for anything but setup. I also ordered two sets of shrouds to play around with, not knowing which would look better on the Jeep.

I fired up the projectors tonight to check out the output, and was totally blown away. The cutoff is immaculate, the light spread evenly, and they have excellent width. One thing I did notice, is there is a noticable "hot spot" right in the middle of the beam, directly under the cutoff step. This isn't a problem or negative aspect, but I'm curious to see how it looks when driving.

Here are a few output pics and randoms I've found online until I can get some real pics tomorrow. All of these are the same projectors.

High beams. This looks like a cheap camera, but you can see the hot spots here.

Comparison to the FXr projector. I think SBXJ has these retro'd.

30' wall shot, this is one projector.

Someone's output pics. First is lowbeam, second is high beam.

Stay tuned...

My original plan was to find a set of LS430 projectors (single xenon) and stuff them into some 7x6 housings. Then I actually DID score a set, and sonofabitch they were WAYYY too big. I would have to do some serious cutting not only to the header panels/rad support, but the projector as well. These have the AFS options, so there's a lot of moldings for the motor and such in the projector. It just wasn't going to happen.

Then I started looking for a cheap way out. Cibie housings with a kit? Or maybe some pre-made suvlight style housings? The pre-made housings were out of control expensive, and I just couldn't get myself to stick a kit inside a halogen housing... I'd be going against so many posts where I've bashed/flamed/laughed at other with it, or preached projectors are the way to go. I also REALLY wanted to keep my high beams. Bi-xenon projectors would be ideal, but I wasn't a huge fan of the FX's or e46's, and most others are just too damn big.

Finally, I found a solution. This wasn't around when I first started looking into a retrofit, and I'm glad someone started making something decent. They're made by a company called Morimoto (japanese I presume), and simply called the "Mini's". They are hands down the smallest bi-xenon projector on the market, and are realatively cheap and readily available.

My parts list is as follows:

-Morimoto Mini's $120 from TRS retrofitsource.com

-Gattling gun shrouds $25 same as above

-E46 extended shrouds $15 'economy' option, same source

-Toyota Denso Ballasts free from work

-Philips Ultinon HID H1 bulbs $150 from ebay

-DDM chiwanese H1 HID kit $35 from ddmtuning.com

The phillips bulbs haven't arrived yet, so I ordered the ddm kit to help me with installation until the new ones come in. On TRS's website they distinclty say 'warranty is void if used with ddm style or other cheap aftermarket kits'. So I'm certainly not trying to use the DDM kit for anything but setup. I also ordered two sets of shrouds to play around with, not knowing which would look better on the Jeep.

I fired up the projectors tonight to check out the output, and was totally blown away. The cutoff is immaculate, the light spread evenly, and they have excellent width. One thing I did notice, is there is a noticable "hot spot" right in the middle of the beam, directly under the cutoff step. This isn't a problem or negative aspect, but I'm curious to see how it looks when driving.

Here are a few output pics and randoms I've found online until I can get some real pics tomorrow. All of these are the same projectors.

High beams. This looks like a cheap camera, but you can see the hot spots here.

Comparison to the FXr projector. I think SBXJ has these retro'd.

30' wall shot, this is one projector.

Someone's output pics. First is lowbeam, second is high beam.

Stay tuned...