- Location

- Port Orchard, WA

usually when I've broken a u-joint, or spit a cap, the ears in the axle shafts mushroom out big time anyway, and there is almost no way to get them outta the knuckle - regardless of how much you've ground. :gee:

I think the 4 corner grinding is fine - personally...

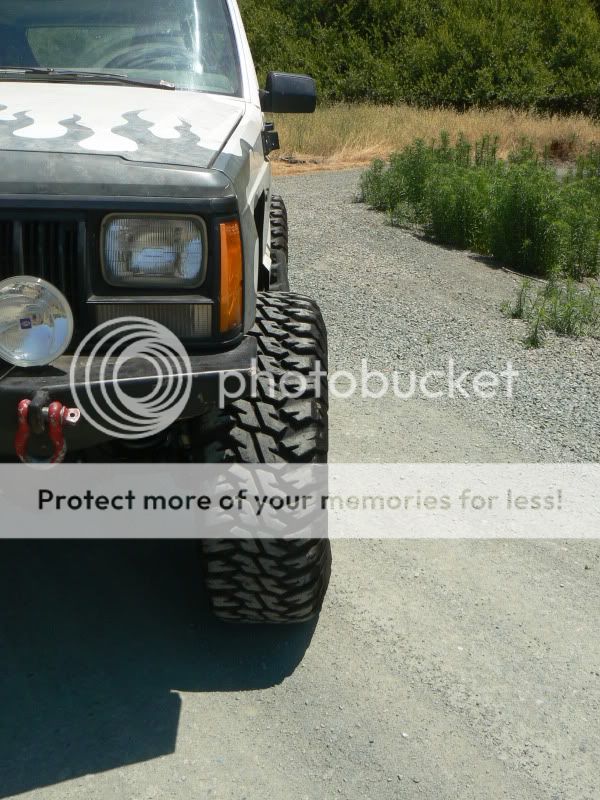

another solution would be to buy the dedenbear Ford outers, and run the ford spindles and brakes - these have much bigger holes in the knuckle, and also a bigger spindle.

I think the 4 corner grinding is fine - personally...

another solution would be to buy the dedenbear Ford outers, and run the ford spindles and brakes - these have much bigger holes in the knuckle, and also a bigger spindle.