- Location

- Virginia City, NV

There is a big chunk of the casting on the top of the 231 that you can hack off if you haven't already. Then bfh time. Smack the floor till it clears.

good to know about that seal. good to see you are getting it done and figuring it all out man.

:shocked:Just admit that you like playing with trannys.

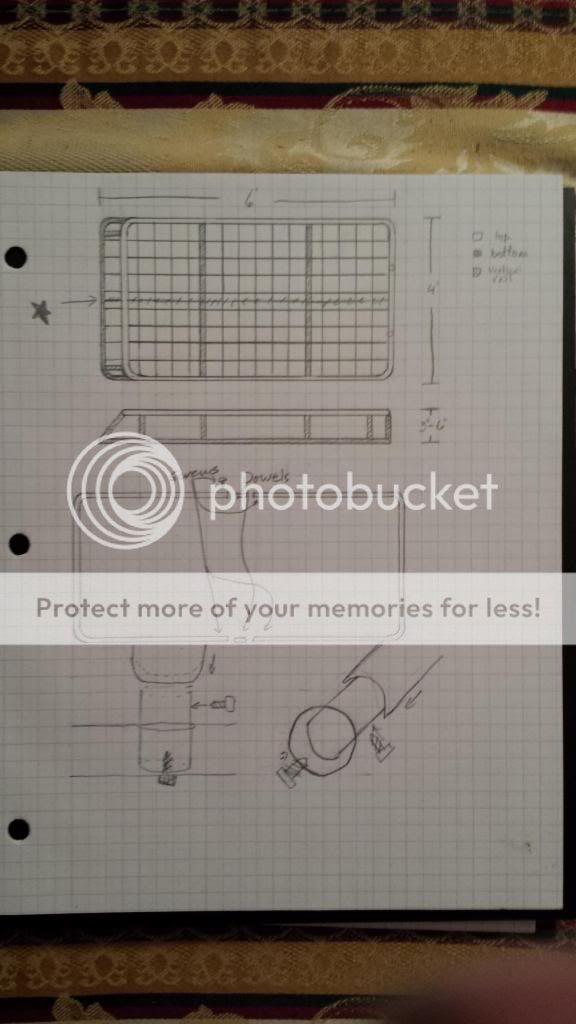

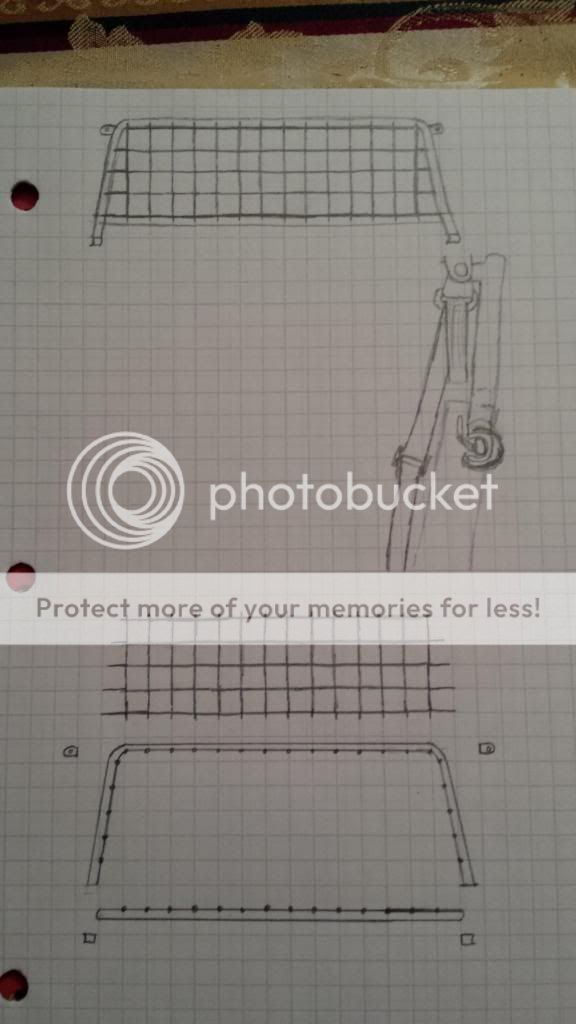

Sweet bro! I got a buddy that needs a rack soon

Come swing by Tim's today if you got some free time!

Nice come up on the rack material. Can you shoot me a pm with a price on a rack and then just the material by itself, if that's alright.

Hey bud.. Since you're so good at dropping transmissions and all...

Wanna help me with my flexplate on my 99?

Can trade fish,coffee, beer etc!?