Just a warning about doing this. If you wear shorts you WILL kill the back of your legs. I thought it was a great idea on my AJs rails too and now I really wish I wouldn't have done it. Both of my kids and I have been attacked by that stuff. It hurts.

its like a trailer hitch, its always gonna bite you...i skate a lot and grip tape does hurt pretty good, i still perfer it to pavement tho

Im thinking about putting it on the inside of the bars to hopefully prevent my legs from being chewed up. That will come at a later date though.

Alright, so here begins the story.

We had a trip planned to go the the Rubicon trail as a break in run for me as well as it to be my last wheeling trip of the summer before I had to go back to Colorado for school. We were going to leave the Bay Area at 4pm on Saturday and head up to Loon Lake, camp Saturday night, and wheel Sunday and Monday, and finally head home Monday night.

Well, if you look back a couple pages you can see my huge list I had to do before I left. Basically finish the boat sides, and add a breather hose for my front axle.

The front breather was a royal PITA because when I did the T&T truss and ARB air locker, I redrilled the breather hose farther back on the diff, which put it right under the truss. Thankfully a friend of mine has the manual dexterity of a monkey and was somehow able to get it in, and a hose routed to it.

I woke up Saturday morning expecting to get everything done pretty fast. I had to make 48 of these little tabs to mount the plastic onto the supports. Took me forever as I had to drill holes in the metal, cut them to length, and then tack weld a nut onto them.

Got those all done, and a friend came over to help me install my seats and seat belts. Hypothetically they were all supposed to just bolt right in. Unfortunately it took him/us almost 2 hours to get them in. A combination of welding splatter, not enough space, and general no fitting right.

Then I was able to use a quick little tool I made (piece of angle iron with a hole drilled in it) to get all of the tabs on the supports. Took me a lot less time then I originally thought, but I was still behind schedule.

After that, I had to figure out how to get the plastic bolted onto those tabs. My dad came up with a good idea of cutting out a piece of cardboard, spray painting the tabs, and then pushing the carboard onto the tabs. That was then used as a template. It worked well, but most of the holes were about 1/2'' off for some reason. So that took way to long.

Anyway, after 12 hours of working, and 4 hours past our time to get out of town, we finally load my POS on the Uhaul trailer. We threw all things I could grab into boxes and headed out.

Looked pretty bad ass on the trailer if I do say so myself.

So we left town, and got some gas before heading up Icehouse Road. My little group.

And me

I barely fit on the trailer. Good thing I had more backspacing then I had before.

So we get up to Loon Lake at 12pm, had a couple of beers and passed out.

Sunday morning we get up and have to finish my Jeep real quick. Luckily it was just finishing up some seat belt bolts and putting the ARB air lines in. Got all that done, and went wheeling. We got all the way to the slabs, and I started to have trouble with my ARB. It seemed like it wasnt working all the time. I tried a ledge, and then had to stop because I didnt have a front locker for some reason.

So this is the only picture I have of me wheeling, and right where I had to stop. We look at my air line going to my front axle and find that at full compression my drivers side upper control arm was hitting my trackbar which then pinched my air line. Quick fix got that fixed, but then I realized that my upper part of my radius arms was hitting my yoke and breaking the ujoint Ubolts. I figured it had self clearanced itself, and put a new ubolt in. Start to pop back up the ledge, and bang, there goes the Ubolt. We decide that if we use the trackbar to shift the axle over to the side so the ubolt wont hit.

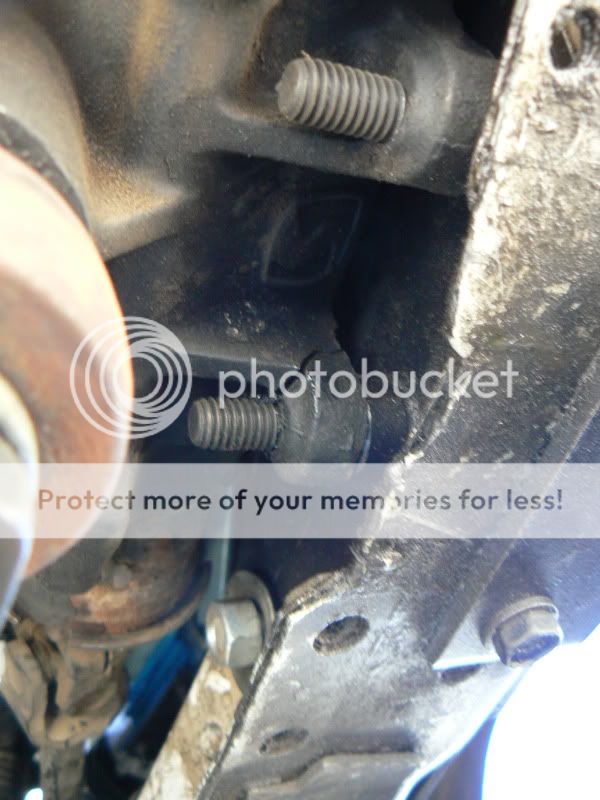

I drive off the ledge, back onto the slabs so we can work on the flat. A friend looks under my Jeep and he sees this:

One of the tabs that bolts the steering box on sheared off. Meaning my weekend was done. I wheeled for about 30 minutes and had this happen. Thankfully I was able to get it back to the trailer with nothing else breaking.

And so ends my story. I had a dang good time, but it sucks that I spent all that time and busting my balls to get it on the trail and that happens.

And it now sits in my garage while I am 1200 miles away in CO for school. Over Thanksgiving break I will be swapping in a new steering box and shifting the axle.

Sorry about the long story.