You might look at Go-Jeeps site for info on using a smaller pipe at the rear. Something elese I have planned for my next build. I plan to use a resonator in place of the muffler. Sort of like a glass pack. That would or should help with your space issue. Then I plan to use a SuperTrap muffler at the rear, I mean just under the bumper. Then I could 'tune' the exhuast with the number of plates. I'd keep the exhust 2.5" or maybe see about going a bit bigger, since I'll have a mild stroker.Stumbled upon this thread and it interests me as I'm making changes to my system and have some similar questions regarding pipe diameter.

Years ago I switched my exhaust to 2.5" pipes all the way back and running a Summit glasspack (all I could fit with the 4-link). Its seemed okay power wise (wasn't really expecting any noticeable gain) but the drone at 2,000-ish rpms is super annoying on the trail with the doors off.

Thinking about returning to 2.25" pipes and I'll be switching to a chambered muffler (I prefer quieter as opposed to loud, as long as it doesn't kill performance/power). I'm hoping this will get rid off the droning sound and the smaller diameter pipes should be a heck of alot easier to fit.

I will not be running a downstream cat (I still have the two pre-cats - its a 2000.)

Is there any downside to choking it down from 2.5" to 2.25" somewhere on the downpipe (after the header, and likely after the two turns)?

- Home

- Forums

- NAXJA Unibody Jeep Technical Forums

- Jeep Cherokee XJ (1984 - 2001)

- Modified Tech Discussion

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The end all Exhaust/ Header thread!

- Thread starter ShoeterMcgav

- Start date

- Location

- In a strange land

I don't see a SuperTrap surviving at the rear. At least not if you take your XJ off road.

Try asking how many folks that have a tailpipe have crushed it coming off a ledge.

And then consider how far you will need to extend that Supertrapp in order to get it to clear the shackle. (Keep in mind, it is more than 2 1/2" in diameter)

Maybe you could try a resonator where the exhaust crosses sides (between the oil pan and the transmission) and then put a glass pack in place of the muffler. However, mufflers don't tend to drop much lower than does a glass pack or a resonator. It is the side to side width where the difference really comes into play. I guess you could say you are reducing the target area.

Try asking how many folks that have a tailpipe have crushed it coming off a ledge.

And then consider how far you will need to extend that Supertrapp in order to get it to clear the shackle. (Keep in mind, it is more than 2 1/2" in diameter)

Maybe you could try a resonator where the exhaust crosses sides (between the oil pan and the transmission) and then put a glass pack in place of the muffler. However, mufflers don't tend to drop much lower than does a glass pack or a resonator. It is the side to side width where the difference really comes into play. I guess you could say you are reducing the target area.

I don't see a SuperTrap surviving at the rear. At least not if you take your XJ off road.

Try asking how many folks that have a tailpipe have crushed it coming off a ledge.

And then consider how far you will need to extend that Supertrapp in order to get it to clear the shackle. (Keep in mind, it is more than 2 1/2" in diameter)

Maybe you could try a resonator where the exhaust crosses sides (between the oil pan and the transmission) and then put a glass pack in place of the muffler. However, mufflers don't tend to drop much lower than does a glass pack or a resonator. It is the side to side width where the difference really comes into play. I guess you could say you are reducing the target area.

Good view. I'll have to see what rear bumper I go with. Then possibly run the Supertrapp through the bumper. I have a IRO rear bumper on my present build. Yeah, way to thin for this to happen. My next build will be more of an Off Road build.

Btw, my muffle did fall off at Winterfest on my last day going out the exit path. Tailpipe wrapped around the axle.

frijolee

NAXJA Forum User

- Location

- Big Island, HI

I thought I'd take a crack at the "end all exhaust / header thread". I'll be stealing quite a bit of info from write-ups scattered throughout my build thread. https://www.naxja.org/forum/showthread.php?t=1081640

FWIW, I'm a bit of a geek and have developed some pretty distinct opinions over the years. First things first: if you really want to get into header and exhaust theory, go buy and read David Vizard's book "How to Build Horsepower".

Ever heard the rule of thumb for a loss-less exhaust you need 2.2 CFM per hp? That's Vizard. The corollary you need to make that useful is his claim that a typical exhaust straight pipe flows ~115 CFM per inch of cross sectional area. Run the math and a 2.5" exhaust flows enough for about 260 hp before losses come into play. If you have a big stroker or a blower maybe you want a bit more. More discussion here: https://www.naxja.org/forum/showpost.php?p=245877178&postcount=149

Engines are air pumps so improve power we really want to consider the air flow from beginning to end. Filter, Intake, TB, intake manifold, heads/cam, header, exhaust, muffler. The upgrade to the last link in the chain always makes the most power, so watch out for dyno results claiming 10% gains. That's very possible, but probably only on a rig that has everything and then adds one obviously missing piece like headers.

Given the title of the thread I'm only going to talk about exhaust and headers.

I started with exhaust. I was dragging the exhaust when wheeling and I absolutely hate the crush point built into the factory downpipe. I cut section across the kink in mine (‘99 4.0) and it’s just stupid.

Maybe I went overkill but I scratch build a 2.5" mandrel bend SS exhaust and tucks entirely above a mid skid because I didn't want to treat my exhaust as disposable like some folks do.

Full build on the exhaust is here: https://www.naxja.org/forum/showpost.php?p=245623739&postcount=50 I do need to repair my muffler bearing since I broke off the mount, but if you're saying, "What muffler bearing, I thought that was joke?", I'll let the other post stand on its own.

No real magic to building exhausts but I can say that I found some test data at one point that had flow numbers on a variety of perf core mufflers. The average was 55% of Vizard's claim for equivalent flow in straight pipe (the numbers are in the post I linked about the theory).

This leads me to a major--if uncommon--epiphany on exhausts. If you care about exhaust performance, I'd recommend jumping up to the next bigger muffler size (IE 3" in and out to go with 2.5" piping). It better matches the flow, but depends if the noise/packaging becomes unacceptable. I wanted the mid skid more so I used a flat spintech muffler that packaged better. I eventually had to swiss cheese my skid for heat management reasons but I can pretty much high center on anything without consequences.

Moving on. I am 100% convinced the necessity of backpressure is a myth and needs to die. I've read some compelling arguments that the test from the 1970s that suggested back pressure helped at the time were fundamentally flawed and instead were reading inadvertent reflected pulse wave tuning at the end of the tailpipe.

What's reflected pulse wave tuning? Well, there are two different mechanisms at play in your exhaust.

1) There's the physical motion of the atoms: here we mostly want to smooth the various pulses from various cylinders into a smooth uniform whole with good velocity via smooth bends, consistent cross sections (crush tube builds are best left to the disposal designs) and equal length runners.

2) However, when the exhaust valve first opens the sudden exposure of high pressure exhaust meeting atmospheric pressure in the outside primary creates a shock wave that travels downstream at the speed of sound far faster than the motion of the atoms themselves.

One basic rule of fluid dynamics and shock waves is that when a pressure pulse hits a major change in cross sectional area there is a reflected pulse wave that goes bouncing back upstream, but the wave inverts so instead of positive pressure it’s pulling a vacuum. If you can time this to arrive back at head during valve overlap (intake valve opening and exhaust valve not quite closed) you get a heck of a scavenging effect that really pulls the last of the exhaust out and really helps get the intake charge moving into the chamber.

But you’re thinking come on Joel, does this really matter than much? Well, air moves via pressure deltas right? The motion of the piston sucking through an okay set of heads sees about a 1 psi pressure delta. In race motors, if it’s over about a 0.5 psi you need more head because it’s too restrictive. That reflected pulse wave measures more like 6-7psi or an order of magnitude more than the motion of the piston itself.

Now the bad news. “Proper” reflected pulse wave tuning requires long tube headers. This is the whole thing that makes long tube headers cool. It takes a certain amount of time (and therefore distance) to travel down and back and arrive at the right moment. The timing is dependent on RPM, so one length of primary is only “tuned” perfectly for one RPM. However, this is also why equal length headers are less of a big deal some manufacturers make it out to me. It doesn’t matter if one tube is perfect at 5000 rpm while the one next to it is ideal at 6000… at all averages out and in reality the shock wave impacts are range of rpm centered around it’s idea. At the end of the day it’s highly possible to design carefully equal length headers while the lengths are equally wrong.

I’d love to see someone design serious long tubes for a Jeep. My guess is that it’d be easiest to do with primaries at about half the ideal length and secondaries out at the full 35-36 inches. Hell if you ran secondaries to 40” you’d have a mid range torque monster.

So building exhausts isn’t too bad, but scratch building headers are another story. I’ve done a few sets and there’s a reason scratch builds for race cars run 3-4k. I wouldn’t recommend it. But what about the headers on the market now? Well, unfortunately because the lengths are wrong we mostly get to focus on optimizing flow (exhaust mechanism #1). Longer is still better since we might get some reflected pulse on the second bounce.

There’s also the longevity factor with headers. The bastards crack on Jeeps with startling frequency. Others have probably talked about this enough so I’ll leave that discussion to others. Suffice it to say that longevity is a big factor and you should add a flex pipe in your exhaust (ref pics above) plus be sure you’re running good motor mounts (SFR, BrownDog, MORE, etc).

I just finished doing a ton of reading and here’s my thoughts on the current market (plus what I picked).

1) The cheapest that's worth looking at is the ATP 101212 (formerly APN). But plenty of folks still fail these and treat them as consumables. The Amazon reviews are pretty bad though. https://smile.amazon.com/ATP-Automotive-Graywerks-101212-Manifold/dp/B000EQLCU2/#customerReviews

Design is okay all things considered. No real effort on runner length (if I can’t have long tubes, more equal lengths are next best for smoothing flow of one pulse of atoms vs. the next one over.) Stamped collectors aren’t ideal as there’s no way they’re running a merge spike at this pricepoint. The biggest issue may be the stress riser from the two to one junction with all those monster MIG welds. The 3:2:1 design is nice for offsetting flow from the front 3 cylinders (each 180 degrees apart) vs. the 3 rear. That said I'm not a big fan of that kink #6 has to go through to enter the first merge.

2) The midrange is folks like JBA, Gibson, Rugged Ridge, and Pacesetter. The first three are very similar to the ATP but at a little higher quality. Feedback in the midrange remains hit or miss on quality/longevity. I actually like that Pacesetter has longer tubes, but I'm not looking to run painted mild steel. Clifford Performance and Borla both had a decent rep (ran across something where Russ Pottenger recommended Clifford) but they’re both discontinued as far as I can tell.

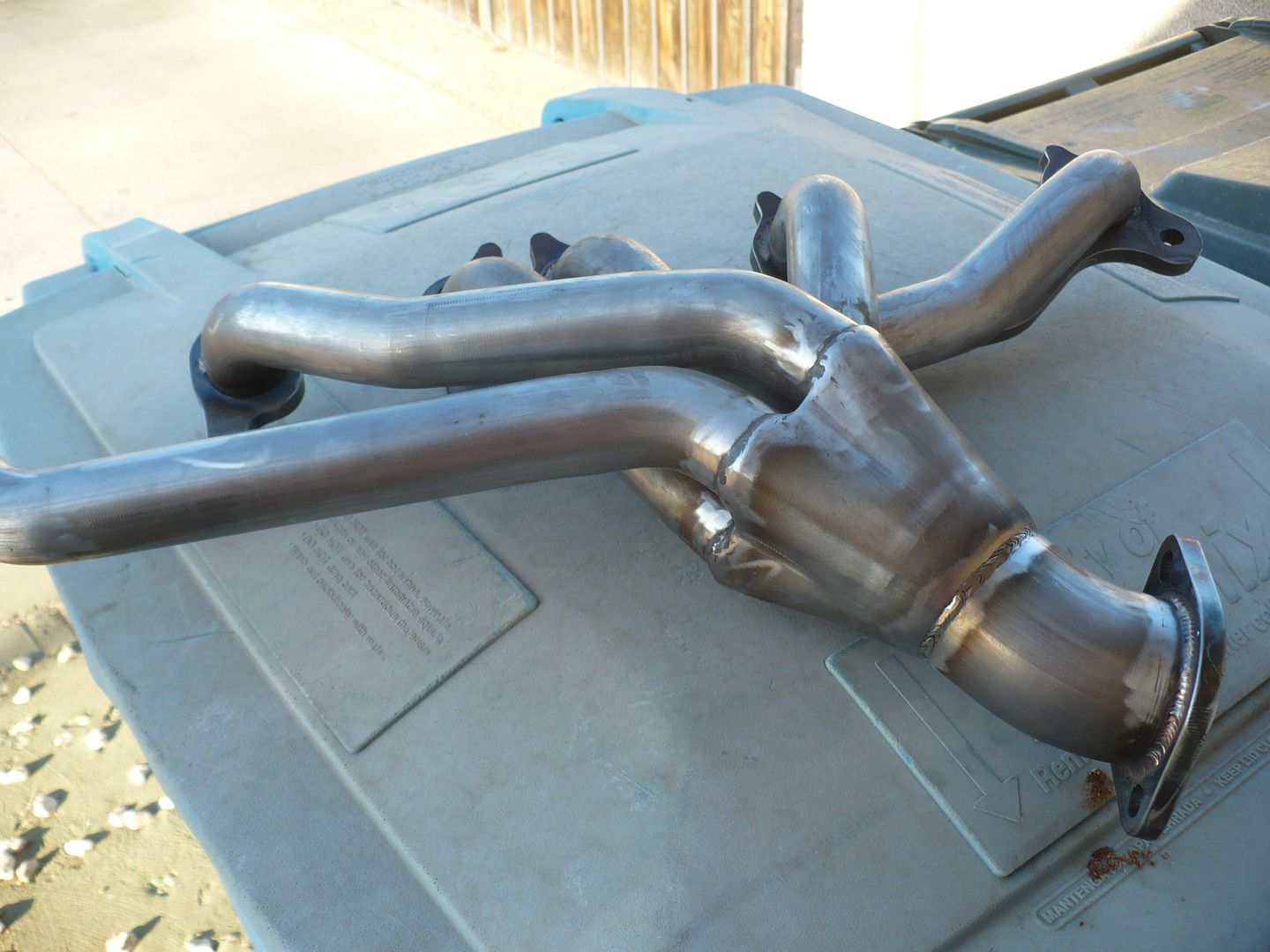

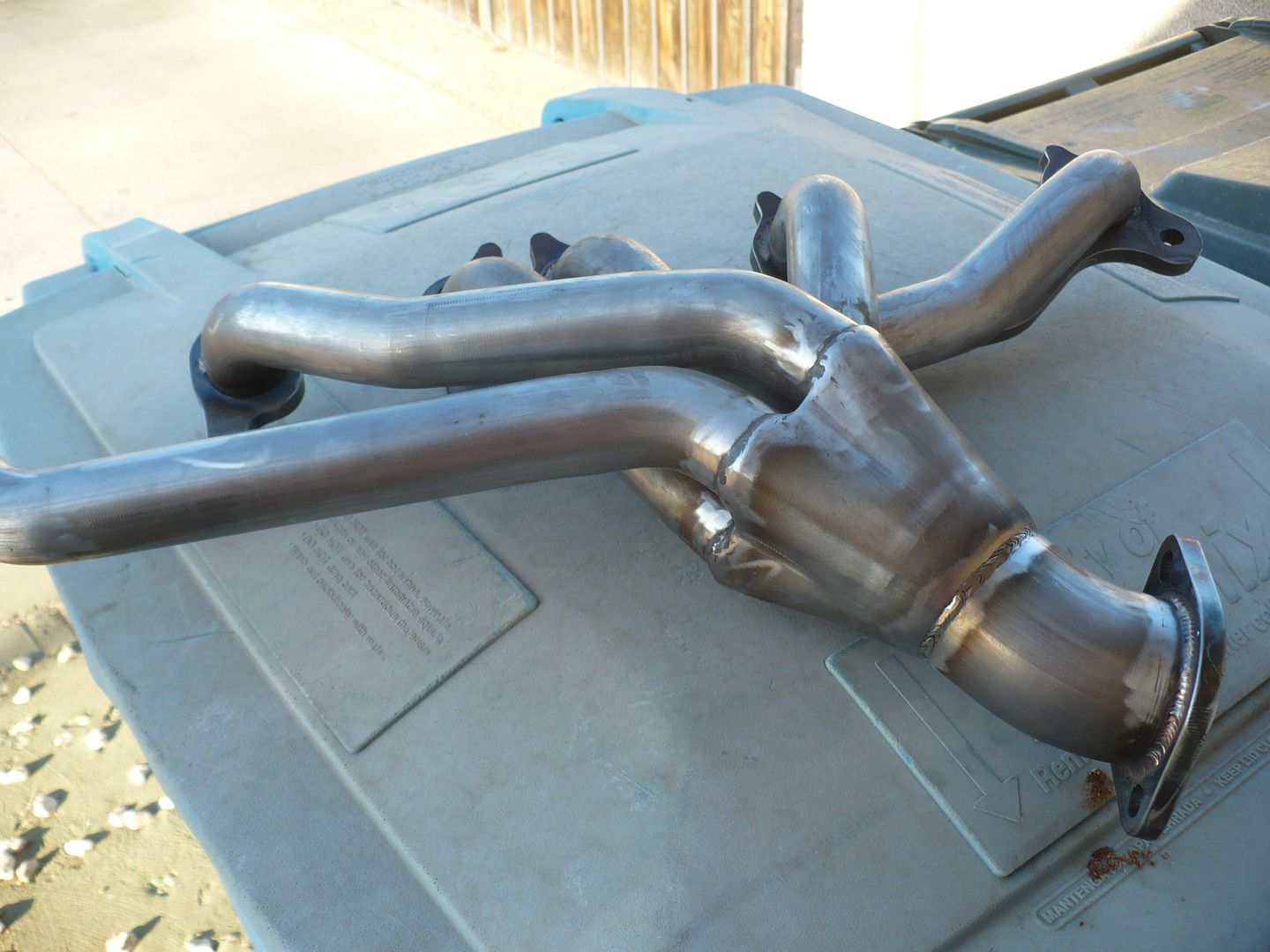

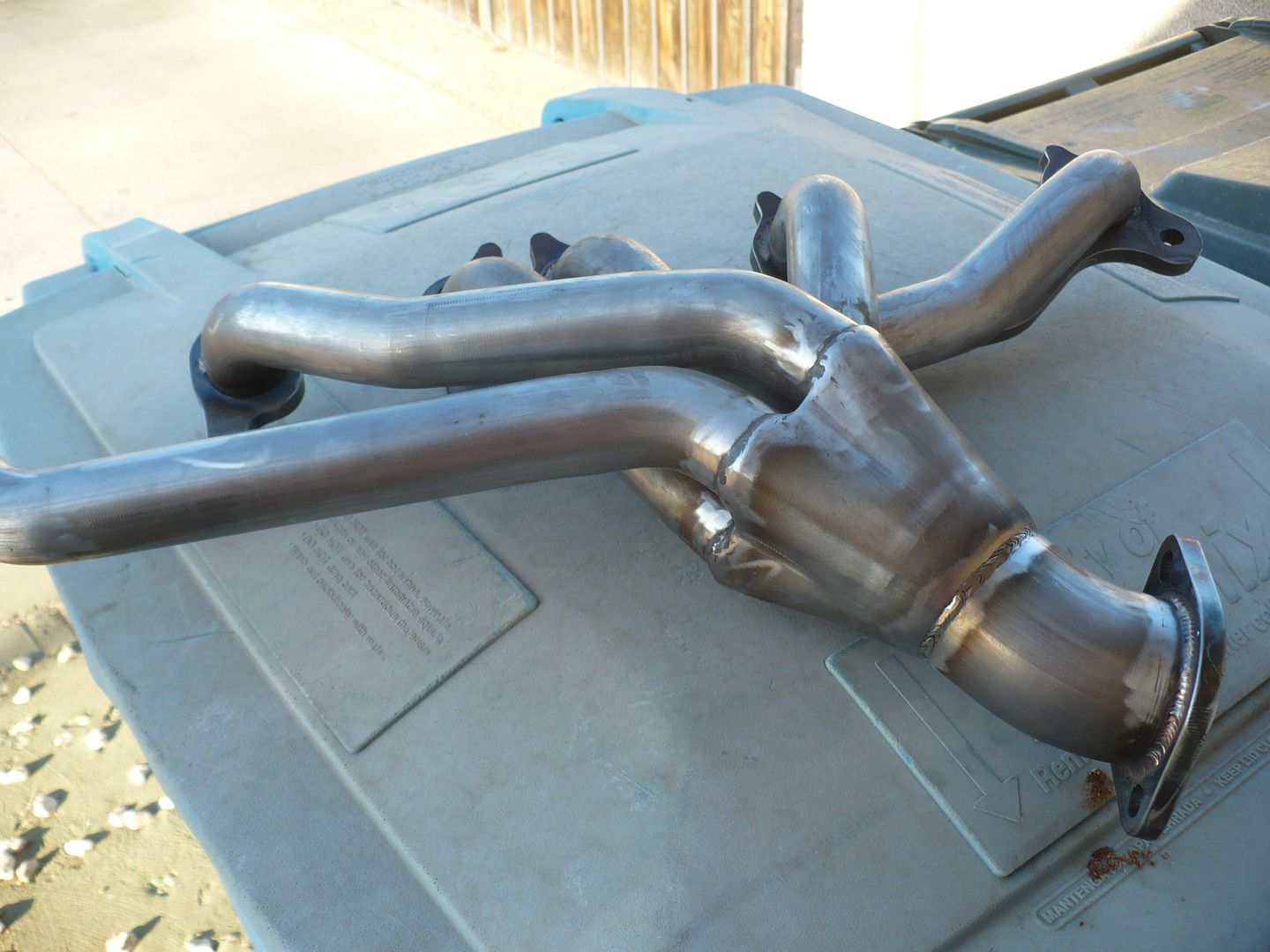

Here’s the Gibson:

You can immediately see the welds are nicer. I’m not so sure about the 6:1 merge though and notably the cost is getting up near that of the Banks that I’d take over the Gibson. Gibson has a limited lifetime warranty if you can get them to honor it (worth looking into).

-Getting toward the high end we have the Banks Revolver. https://www.bankspower.com/i-2581-e...99-jeep-wrangler-4-0l-1991-1998-cherokee.html. Downside quite a few folks still report failures, IE https://www.naxja.org/forum/showthread.php?t=1108130. That said, Petty Cash Racing (4643) runs a revolver and has had good success.

Petty Cash Racing (4643) runs a revolver and has had good success.

I like the design and Banks does have the 2nd longest warranty I'm aware of at 5 years. It's technically available on Amazon prime so likely free shipping (but be warned Banks won't honor your warranty on a purchase through Amazon). I can't imagine that giant 6-1 void really doing great stuff for flow without a serious merge spike. I do respect Banks as company and Gale Banks as a person and that’s always a good reason to support a given company.

-Which brings me to the top end of the market (Gibson is marked down enough that I have them as mid-high). Here there are two players I’m aware of: Doug Thorley and the AFE Twisted Steel header.

I don’t really get the Doug Thorley. They’re almost the most expensive on the market but they looked like paying top shelf money for an odd take on the most common ATP layout.

The #1 runner appears to be excessively long and 3 and 4 seem to be excessively short. It uses the same basic stamped collector quite a few cheaper options run. The nail in coffin for me was when I ran across a few horror stories with unfulfilled warranty claims.

The good news on the Thorley is that if the welding is quality that should always justify some premium. Ceramic coating should help keep underhood temps down. Full info here if you’re checking them out.

http://www.dougthorleyheaders.com/h...--grand-cherokee-4.0l-h-o-tri-y-headers_15717

Finally, here’s my choice as the nerd trying to leverage what knowledge I can. AFE twisted steel. https://afepower.com/afe-power-48-46201-twisted-steel-headers.

The big upside to the AFE is that it's 14G steel (significantly heavier wall than most), uses actual merges instead of a stamped collector, and it's 100% TIG welded. Even if I do crack it, it should be notably easier to repair and toss back on. It comes with a 2 year warranty. They include Fel Pro gaskets. I like that they're using several radius bends to give the smoothest path while watching lengths. Hell, they even got the firing order perfect: 1-5-3-6-2-4 means that each group of three sees pulses at the local merge in a symmetric rotational sequence. The shorter path cylinders (4 though 6) have that merge lower to increase lengths.

Crap like that gets me jazzed, so earlier today I pulled the trigger. Price is steep, but seems like you get what you pay for... The chatter on headers starts in my build thread here, if you’re like me and go scrounging for ever bit of info you can find: https://www.naxja.org/forum/showpost.php?p=246730744&postcount=537

The only other downside of the AFE is that price seems to have them be a good bit less common than some. Despite having fewer reviews, the feedback seems very good for the few reviews it does have. Check out Amazon: https://smile.amazon.com/aFe-48-46201-Stainless-Twisted-Wrangler/dp/B005URAXX2/#customerReviews. One weird twist on Amazon's rankings... at the time of this writing, there are eleven 5 star reviews and one 1 star, which Amazon claims equals 32% 1 star reviews and a 3.7 star average. That math don't work. I think their algorithm is broken.

Anyways, the sole 1 star was a small area that got missed on original welding. Should it happen on a header this expensive? No. Am I worried out it? Also no.

I’ll try to post more as I learn (probably build thread).

Forgive me for writing a book but I thought a thread titled “the end all exhaust / header thread” needed a bit more content to justify the name. Oh, full disclaimer, my thoughts are my own and yours may vary. There are always multiple ways to skin a cat.

Good luck and happy wrenching.

-Joel (aka Frijolee)

FWIW, I'm a bit of a geek and have developed some pretty distinct opinions over the years. First things first: if you really want to get into header and exhaust theory, go buy and read David Vizard's book "How to Build Horsepower".

Ever heard the rule of thumb for a loss-less exhaust you need 2.2 CFM per hp? That's Vizard. The corollary you need to make that useful is his claim that a typical exhaust straight pipe flows ~115 CFM per inch of cross sectional area. Run the math and a 2.5" exhaust flows enough for about 260 hp before losses come into play. If you have a big stroker or a blower maybe you want a bit more. More discussion here: https://www.naxja.org/forum/showpost.php?p=245877178&postcount=149

Engines are air pumps so improve power we really want to consider the air flow from beginning to end. Filter, Intake, TB, intake manifold, heads/cam, header, exhaust, muffler. The upgrade to the last link in the chain always makes the most power, so watch out for dyno results claiming 10% gains. That's very possible, but probably only on a rig that has everything and then adds one obviously missing piece like headers.

Given the title of the thread I'm only going to talk about exhaust and headers.

I started with exhaust. I was dragging the exhaust when wheeling and I absolutely hate the crush point built into the factory downpipe. I cut section across the kink in mine (‘99 4.0) and it’s just stupid.

Maybe I went overkill but I scratch build a 2.5" mandrel bend SS exhaust and tucks entirely above a mid skid because I didn't want to treat my exhaust as disposable like some folks do.

Full build on the exhaust is here: https://www.naxja.org/forum/showpost.php?p=245623739&postcount=50 I do need to repair my muffler bearing since I broke off the mount, but if you're saying, "What muffler bearing, I thought that was joke?", I'll let the other post stand on its own.

No real magic to building exhausts but I can say that I found some test data at one point that had flow numbers on a variety of perf core mufflers. The average was 55% of Vizard's claim for equivalent flow in straight pipe (the numbers are in the post I linked about the theory).

This leads me to a major--if uncommon--epiphany on exhausts. If you care about exhaust performance, I'd recommend jumping up to the next bigger muffler size (IE 3" in and out to go with 2.5" piping). It better matches the flow, but depends if the noise/packaging becomes unacceptable. I wanted the mid skid more so I used a flat spintech muffler that packaged better. I eventually had to swiss cheese my skid for heat management reasons but I can pretty much high center on anything without consequences.

Moving on. I am 100% convinced the necessity of backpressure is a myth and needs to die. I've read some compelling arguments that the test from the 1970s that suggested back pressure helped at the time were fundamentally flawed and instead were reading inadvertent reflected pulse wave tuning at the end of the tailpipe.

What's reflected pulse wave tuning? Well, there are two different mechanisms at play in your exhaust.

1) There's the physical motion of the atoms: here we mostly want to smooth the various pulses from various cylinders into a smooth uniform whole with good velocity via smooth bends, consistent cross sections (crush tube builds are best left to the disposal designs) and equal length runners.

2) However, when the exhaust valve first opens the sudden exposure of high pressure exhaust meeting atmospheric pressure in the outside primary creates a shock wave that travels downstream at the speed of sound far faster than the motion of the atoms themselves.

One basic rule of fluid dynamics and shock waves is that when a pressure pulse hits a major change in cross sectional area there is a reflected pulse wave that goes bouncing back upstream, but the wave inverts so instead of positive pressure it’s pulling a vacuum. If you can time this to arrive back at head during valve overlap (intake valve opening and exhaust valve not quite closed) you get a heck of a scavenging effect that really pulls the last of the exhaust out and really helps get the intake charge moving into the chamber.

But you’re thinking come on Joel, does this really matter than much? Well, air moves via pressure deltas right? The motion of the piston sucking through an okay set of heads sees about a 1 psi pressure delta. In race motors, if it’s over about a 0.5 psi you need more head because it’s too restrictive. That reflected pulse wave measures more like 6-7psi or an order of magnitude more than the motion of the piston itself.

Now the bad news. “Proper” reflected pulse wave tuning requires long tube headers. This is the whole thing that makes long tube headers cool. It takes a certain amount of time (and therefore distance) to travel down and back and arrive at the right moment. The timing is dependent on RPM, so one length of primary is only “tuned” perfectly for one RPM. However, this is also why equal length headers are less of a big deal some manufacturers make it out to me. It doesn’t matter if one tube is perfect at 5000 rpm while the one next to it is ideal at 6000… at all averages out and in reality the shock wave impacts are range of rpm centered around it’s idea. At the end of the day it’s highly possible to design carefully equal length headers while the lengths are equally wrong.

I’d love to see someone design serious long tubes for a Jeep. My guess is that it’d be easiest to do with primaries at about half the ideal length and secondaries out at the full 35-36 inches. Hell if you ran secondaries to 40” you’d have a mid range torque monster.

So building exhausts isn’t too bad, but scratch building headers are another story. I’ve done a few sets and there’s a reason scratch builds for race cars run 3-4k. I wouldn’t recommend it. But what about the headers on the market now? Well, unfortunately because the lengths are wrong we mostly get to focus on optimizing flow (exhaust mechanism #1). Longer is still better since we might get some reflected pulse on the second bounce.

There’s also the longevity factor with headers. The bastards crack on Jeeps with startling frequency. Others have probably talked about this enough so I’ll leave that discussion to others. Suffice it to say that longevity is a big factor and you should add a flex pipe in your exhaust (ref pics above) plus be sure you’re running good motor mounts (SFR, BrownDog, MORE, etc).

I just finished doing a ton of reading and here’s my thoughts on the current market (plus what I picked).

1) The cheapest that's worth looking at is the ATP 101212 (formerly APN). But plenty of folks still fail these and treat them as consumables. The Amazon reviews are pretty bad though. https://smile.amazon.com/ATP-Automotive-Graywerks-101212-Manifold/dp/B000EQLCU2/#customerReviews

Design is okay all things considered. No real effort on runner length (if I can’t have long tubes, more equal lengths are next best for smoothing flow of one pulse of atoms vs. the next one over.) Stamped collectors aren’t ideal as there’s no way they’re running a merge spike at this pricepoint. The biggest issue may be the stress riser from the two to one junction with all those monster MIG welds. The 3:2:1 design is nice for offsetting flow from the front 3 cylinders (each 180 degrees apart) vs. the 3 rear. That said I'm not a big fan of that kink #6 has to go through to enter the first merge.

2) The midrange is folks like JBA, Gibson, Rugged Ridge, and Pacesetter. The first three are very similar to the ATP but at a little higher quality. Feedback in the midrange remains hit or miss on quality/longevity. I actually like that Pacesetter has longer tubes, but I'm not looking to run painted mild steel. Clifford Performance and Borla both had a decent rep (ran across something where Russ Pottenger recommended Clifford) but they’re both discontinued as far as I can tell.

Here’s the Gibson:

You can immediately see the welds are nicer. I’m not so sure about the 6:1 merge though and notably the cost is getting up near that of the Banks that I’d take over the Gibson. Gibson has a limited lifetime warranty if you can get them to honor it (worth looking into).

-Getting toward the high end we have the Banks Revolver. https://www.bankspower.com/i-2581-e...99-jeep-wrangler-4-0l-1991-1998-cherokee.html. Downside quite a few folks still report failures, IE https://www.naxja.org/forum/showthread.php?t=1108130. That said,

Petty Cash Racing (4643) runs a revolver and has had good success.

Petty Cash Racing (4643) runs a revolver and has had good success.I like the design and Banks does have the 2nd longest warranty I'm aware of at 5 years. It's technically available on Amazon prime so likely free shipping (but be warned Banks won't honor your warranty on a purchase through Amazon). I can't imagine that giant 6-1 void really doing great stuff for flow without a serious merge spike. I do respect Banks as company and Gale Banks as a person and that’s always a good reason to support a given company.

-Which brings me to the top end of the market (Gibson is marked down enough that I have them as mid-high). Here there are two players I’m aware of: Doug Thorley and the AFE Twisted Steel header.

I don’t really get the Doug Thorley. They’re almost the most expensive on the market but they looked like paying top shelf money for an odd take on the most common ATP layout.

The #1 runner appears to be excessively long and 3 and 4 seem to be excessively short. It uses the same basic stamped collector quite a few cheaper options run. The nail in coffin for me was when I ran across a few horror stories with unfulfilled warranty claims.

The good news on the Thorley is that if the welding is quality that should always justify some premium. Ceramic coating should help keep underhood temps down. Full info here if you’re checking them out.

http://www.dougthorleyheaders.com/h...--grand-cherokee-4.0l-h-o-tri-y-headers_15717

Finally, here’s my choice as the nerd trying to leverage what knowledge I can. AFE twisted steel. https://afepower.com/afe-power-48-46201-twisted-steel-headers.

The big upside to the AFE is that it's 14G steel (significantly heavier wall than most), uses actual merges instead of a stamped collector, and it's 100% TIG welded. Even if I do crack it, it should be notably easier to repair and toss back on. It comes with a 2 year warranty. They include Fel Pro gaskets. I like that they're using several radius bends to give the smoothest path while watching lengths. Hell, they even got the firing order perfect: 1-5-3-6-2-4 means that each group of three sees pulses at the local merge in a symmetric rotational sequence. The shorter path cylinders (4 though 6) have that merge lower to increase lengths.

Crap like that gets me jazzed, so earlier today I pulled the trigger. Price is steep, but seems like you get what you pay for... The chatter on headers starts in my build thread here, if you’re like me and go scrounging for ever bit of info you can find: https://www.naxja.org/forum/showpost.php?p=246730744&postcount=537

The only other downside of the AFE is that price seems to have them be a good bit less common than some. Despite having fewer reviews, the feedback seems very good for the few reviews it does have. Check out Amazon: https://smile.amazon.com/aFe-48-46201-Stainless-Twisted-Wrangler/dp/B005URAXX2/#customerReviews. One weird twist on Amazon's rankings... at the time of this writing, there are eleven 5 star reviews and one 1 star, which Amazon claims equals 32% 1 star reviews and a 3.7 star average. That math don't work. I think their algorithm is broken.

Anyways, the sole 1 star was a small area that got missed on original welding. Should it happen on a header this expensive? No. Am I worried out it? Also no.

I’ll try to post more as I learn (probably build thread).

Forgive me for writing a book but I thought a thread titled “the end all exhaust / header thread” needed a bit more content to justify the name. Oh, full disclaimer, my thoughts are my own and yours may vary. There are always multiple ways to skin a cat.

Good luck and happy wrenching.

-Joel (aka Frijolee)

Last edited:

My 90 has the renix TB so not bored out. It does have Five O bosche (green) injectors (4 Hole?) modified MAP voltage and Really old multi ground spark plugs. Only way I could pass inspection was with the MAP adjustment and the plugs.

The Renix can be bored straight to 58mm. I think there are some who bore it to 60mm. Years ago someone in FL was boring them out to 60mm. I remember him as 'Bell'. I think I remember a 1 in 3 or 4 scrap rate. The porosity of the castings.

OK, to add to the header stuff and exhaust. I did have a Pacesetter around 2002. At that time they did have a Ceramic coating option call Amour Coat. Mine had it and it seemed good. I do have a Clifford. At some point they did a dual or split collector. I have one of those with their Black Ceramic coating. I have not actually run it. I do have it installed. Some of the bolts is a pain. Also, I've hear the split collector had issues cracking.

As Frijolee talks about exhaust pulse. I read 'Performance with Economy' (Also David Vizard)years ago. Mainly it was for V-8s. The Late 70s to late 80's were dark times for performance. On V-8's it is possible to 'X' or cross the exhaust. This has two effects. One a shared exhaust, so potentially twice the area. The other is and mainly for is to scavenge the other exhaust pulse. Also, in the book was the talk of an Anti-Reversion cone in the header, at the exhaust port. It is a cone that acts like a one way valve. Hinders the exhaust gasses from flowing back into the chamber.

Last edited:

- Location

- In a strange land

I thought I'd take a crack at the "end all exhaust / header thread". I'll be stealing quite a bit of info from write-ups scattered throughout my build thread. https://www.naxja.org/forum/showthread.php?t=1081640

FWIW, I'm a bit of a geek and have developed some pretty distinct opinions over the years. First things first: if you really want to get into header and exhaust theory, go buy and read David Vizard's book "How to Build Horsepower".

Ever heard the rule of thumb for a loss-less exhaust you need 2.2 CFM per hp? That's Vizard. The corollary you need to make that useful is his claim that a typical exhaust straight pipe flows ~115 CFM per inch of cross sectional area. Run the math and a 2.5" exhaust flows enough for about 260 hp before losses come into play. If you have a big stroker or a blower maybe you want a bit more. More discussion here: https://www.naxja.org/forum/showpost.php?p=245877178&postcount=149

Engines are air pumps so improve power we really want to consider the air flow from beginning to end. Filter, Intake, TB, intake manifold, heads/cam, header, exhaust, muffler. The upgrade to the last link in the chain always makes the most power, so watch out for dyno results claiming 10% gains. That's very possible, but probably only on a rig that has everything and then adds one obviously missing piece like headers.

Given the title of the thread I'm only going to talk about exhaust and headers.

I started with exhaust. I was dragging the exhaust when wheeling and I absolutely hate the crush point built into the factory downpipe. I cut section across the kink in mine (‘99 4.0) and it’s just stupid.

Maybe I went overkill but I scratch build a 2.5" mandrel bend SS exhaust and tucks entirely above a mid skid because I didn't want to treat my exhaust as disposable like some folks do.

Full build on the exhaust is here: https://www.naxja.org/forum/showpost.php?p=245623739&postcount=50 I do need to repair my muffler bearing since I broke off the mount, but if you're saying, "What muffler bearing, I thought that was joke?", I'll let the other post stand on its own.

No real magic to building exhausts but I can say that I found some test data at one point that had flow numbers on a variety of perf core mufflers. The average was 55% of Vizard's claim for equivalent flow in straight pipe (the numbers are in the post I linked about the theory).

This leads me to a major--if uncommon--epiphany on exhausts. If you care about exhaust performance, I'd recommend jumping up to the next bigger muffler size (IE 3" in and out to go with 2.5" piping). It better matches the flow, but depends if the noise/packaging becomes unacceptable. I wanted the mid skid more so I used a flat spintech muffler that packaged better. I eventually had to swiss cheese my skid for heat management reasons but I can pretty much high center on anything without consequences.

Moving on. I am 100% convinced the necessity of backpressure is a myth and needs to die. I've read some compelling arguments that the test from the 1970s that suggested back pressure helped at the time were fundamentally flawed and instead were reading inadvertent reflected pulse wave tuning at the end of the tailpipe.

What's reflected pulse wave tuning? Well, there are two different mechanisms at play in your exhaust.

1) There's the physical motion of the atoms: here we mostly want to smooth the various pulses from various cylinders into a smooth uniform whole with good velocity via smooth bends, consistent cross sections (crush tube builds are best left to the disposal designs) and equal length runners.

2) However, when the exhaust valve first opens the sudden exposure of high pressure exhaust meeting atmospheric pressure in the outside primary creates a shock wave that travels downstream at the speed of sound far faster than the motion of the atoms themselves.

One basic rule of fluid dynamics and shock waves is that when a pressure pulse hits a major change in cross sectional area there is a reflected pulse wave that goes bouncing back upstream, but the wave inverts so instead of positive pressure it’s pulling a vacuum. If you can time this to arrive back at head during valve overlap (intake valve opening and exhaust valve not quite closed) you get a heck of a scavenging effect that really pulls the last of the exhaust out and really helps get the intake charge moving into the chamber.

But you’re thinking come on Joel, does this really matter than much? Well, air moves via pressure deltas right? The motion of the piston sucking through an okay set of heads sees about a 1 psi pressure delta. In race motors, if it’s over about a 0.5 psi you need more head because it’s too restrictive. That reflected pulse wave measures more like 6-7psi or an order of magnitude more than the motion of the piston itself.

Now the bad news. “Proper” reflected pulse wave tuning requires long tube headers. This is the whole thing that makes long tube headers cool. It takes a certain amount of time (and therefore distance) to travel down and back and arrive at the right moment. The timing is dependent on RPM, so one length of primary is only “tuned” perfectly for one RPM. However, this is also why equal length headers are less of a big deal some manufacturers make it out to me. It doesn’t matter if one tube is perfect at 5000 rpm while the one next to it is ideal at 6000… at all averages out and in reality the shock wave impacts are range of rpm centered around it’s idea. At the end of the day it’s highly possible to design carefully equal length headers while the lengths are equally wrong.

I’d love to see someone design serious long tubes for a Jeep. My guess is that it’d be easiest to do with primaries at about half the ideal length and secondaries out at the full 35-36 inches. Hell if you ran secondaries to 40” you’d have a mid range torque monster.

So building exhausts isn’t too bad, but scratch building headers are another story. I’ve done a few sets and there’s a reason scratch builds for race cars run 3-4k. I wouldn’t recommend it. But what about the headers on the market now? Well, unfortunately because the lengths are wrong we mostly get to focus on optimizing flow (exhaust mechanism #1). Longer is still better since we might get some reflected pulse on the second bounce.

There’s also the longevity factor with headers. The bastards crack on Jeeps with startling frequency. Others have probably talked about this enough so I’ll leave that discussion to others. Suffice it to say that longevity is a big factor and you should add a flex pipe in your exhaust (ref pics above) plus be sure you’re running good motor mounts (SFR, BrownDog, MORE, etc).

I just finished doing a ton of reading and here’s my thoughts on the current market (plus what I picked).

1) The cheapest that's worth looking at is the ATP 101212 (formerly APN). But plenty of folks still fail these and treat them as consumables. The Amazon reviews are pretty bad though. https://smile.amazon.com/ATP-Automotive-Graywerks-101212-Manifold/dp/B000EQLCU2/#customerReviews

Design is okay all things considered. No real effort on runner length (if I can’t have long tubes, more equal lengths are next best for smoothing flow of one pulse of atoms vs. the next one over.) Stamped collectors aren’t ideal as there’s no way they’re running a merge spike at this pricepoint. The biggest issue may be the stress riser from the two to one junction with all those monster MIG welds. The 3:2:1 design is nice for offsetting flow from the front 3 cylinders (each 180 degrees apart) vs. the 3 rear. That said I'm not a big fan of that kink #6 has to go through to enter the first merge.

2) The midrange is folks like JBA, Gibson, Rugged Ridge, and Pacesetter. The first three are very similar to the ATP but at a little higher quality. Feedback in the midrange remains hit or miss on quality/longevity. I actually like that Pacesetter has longer tubes, but I'm not looking to run painted mild steel. Clifford Performance and Borla both had a decent rep (ran across something where Russ Pottenger recommended Clifford) but they’re both discontinued as far as I can tell.

Here’s the Gibson:

You can immediately see the welds are nicer. I’m not so sure about the 6:1 merge though and notably the cost is getting up near that of the Banks that I’d take over the Gibson. Gibson has a limited lifetime warranty if you can get them to honor it (worth looking into).

-Getting toward the high end we have the Banks Revolver. https://www.bankspower.com/i-2581-e...99-jeep-wrangler-4-0l-1991-1998-cherokee.html. Downside quite a few folks still report failures, IE https://www.naxja.org/forum/showthread.php?t=1108130. That said,Petty Cash Racing (4643) runs a revolver and has had good success.

I like the design and Banks does have the 2nd longest warranty I'm aware of at 5 years. It's technically available on Amazon prime so likely free shipping (but be warned Banks won't honor your warranty on a purchase through Amazon). I can't imagine that giant 6-1 void really doing great stuff for flow without a serious merge spike. I do respect Banks as company and Gale Banks as a person and that’s always a good reason to support a given company.

-Which brings me to the top end of the market (Gibson is marked down enough that I have them as mid-high). Here there are two players I’m aware of: Doug Thorley and the AFE Twisted Steel header.

I don’t really get the Doug Thorley. They’re almost the most expensive on the market but they looked like paying top shelf money for an odd take on the most common ATP layout.

The #1 runner appears to be excessively long and 3 and 4 seem to be excessively short. It uses the same basic stamped collector quite a few cheaper options run. The nail in coffin for me was when I ran across a few horror stories with unfulfilled warranty claims.

The good news on the Thorley is that if the welding is quality that should always justify some premium. Ceramic coating should help keep underhood temps down. Full info here if you’re checking them out.

http://www.dougthorleyheaders.com/h...--grand-cherokee-4.0l-h-o-tri-y-headers_15717

Finally, here’s my choice as the nerd trying to leverage what knowledge I can. AFE twisted steel. https://afepower.com/afe-power-48-46201-twisted-steel-headers.

The big upside to the AFE is that it's 14G steel (significantly heavier wall than most), uses actual merges instead of a stamped collector, and it's 100% TIG welded. Even if I do crack it, it should be notably easier to repair and toss back on. It comes with a 2 year warranty. They include Fel Pro gaskets. I like that they're using several radius bends to give the smoothest path while watching lengths. Hell, they even got the firing order perfect: 1-5-3-6-2-4 means that each group of three sees pulses at the local merge in a symmetric rotational sequence. The shorter path cylinders (4 though 6) have that merge lower to increase lengths.

Crap like that gets me jazzed, so earlier today I pulled the trigger. Price is steep, but seems like you get what you pay for... The chatter on headers starts in my build thread here, if you’re like me and go scrounging for ever bit of info you can find: https://www.naxja.org/forum/showpost.php?p=246730744&postcount=537

The only other downside of the AFE is that price seems to have them be a good bit less common than some. Despite having fewer reviews, the feedback seems very good for the few reviews it does have. Check out Amazon: https://smile.amazon.com/aFe-48-46201-Stainless-Twisted-Wrangler/dp/B005URAXX2/#customerReviews. One weird twist on Amazon's rankings... at the time of this writing, there are eleven 5 star reviews and one 1 star, which Amazon claims equals 32% 1 star reviews and a 3.7 star average. That math don't work. I think their algorithm is broken.

Anyways, the sole 1 star was a small area that got missed on original welding. Should it happen on a header this expensive? No. Am I worried out it? Also no.

I’ll try to post more as I learn (probably build thread).

Forgive me for writing a book but I thought a thread titled “the end all exhaust / header thread” needed a bit more content to justify the name. Oh, full disclaimer, my thoughts are my own and yours may vary. There are always multiple ways to skin a cat.

Good luck and happy wrenching.

-Joel (aka Frijolee)

Very nicely done. Good job.

(from an ex-manufacturing engineer for Hooker Headers)

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

It's all about the "intended" expectations. My motor was specifically built based on a Banks Revolver so no matter what happens to it I will have to replace it with another Revolver. As is it's about 3.5 yrs old but I may remove it and it ceramic coated in the mean time.

maxbraketorque

NAXJA Forum User

- Location

- PDX

Very nicely done. Good job.

(from an ex-manufacturing engineer for Hooker Headers)

I was thinking the same thing. Super clean routing and welds on the exhaust.

On the topic of headers, one thing that makes me shy away from trying a tubular header is that any attempt to create an equal length or longer tube primary is going to add a lot more tubing surface area in the engine compartment, and it seems that would substantially increase the waste heat in the engine compartment. Ceramic coating would seem to be needed to alleviate this.

- Location

- In a strange land

Ceramic coating definitely helps, but stainless steel is good. The thermal conductivity of stainless is noticeably lower than that of carbon steel. And stainless retains its properties, whereas ceramic coating degrades over time, eventually failing completely.

maxbraketorque

NAXJA Forum User

- Location

- PDX

I looked up the thermal conductivity of 304 SS and cast steel not too long ago for consideration on the possibility of switching to a tubular header. My recollection is that the thermal conductivity of 304 SS is 1/3 that of cast steel, but tubular header wall thickness is probably about 1/3 of cast steel, so I think the heat transfer per unit length of header is a wash between 304 SS and cast steel.

When accounting for the additional exposed surface area of an equal length or long tube header, waste heat goes up. My feeling is that a polished 304 SS surface could reduce heat transfer, but I couldn't find any good evidence of it. Thermal coating would seem to be the best option if it will last a while, but sounds like you are saying it doesn't last that long. Perhaps a ventilated hood takes care of the issue more easily?

When accounting for the additional exposed surface area of an equal length or long tube header, waste heat goes up. My feeling is that a polished 304 SS surface could reduce heat transfer, but I couldn't find any good evidence of it. Thermal coating would seem to be the best option if it will last a while, but sounds like you are saying it doesn't last that long. Perhaps a ventilated hood takes care of the issue more easily?

- Location

- In a strange land

The challenge with ceramic coating is that it is a galvanically active, sacrificial coating. It lasts longest if hot and dry. Moisture kills it quickly. IOW, it will last longer on a daily driver than on a garage queen (concrete slabs generally wick up soil moisture and release it into the atmosphere). Either way, at some point it is going to expire, and then the whole coating tends to give it up.

If you live in an area with low humidity you will have better results than if you are in a high humidity area.

ETA: Regarding the stainless vs carbon steel--One of the tricks to getting headers to pass CARB E.O. tests is to make them out of stainless steel. Just that difference in retained heat can be enough to make the difference--issue being the O2 sensor and keeping the exhaust temps up until the gases pass that sensor.

If you live in an area with low humidity you will have better results than if you are in a high humidity area.

ETA: Regarding the stainless vs carbon steel--One of the tricks to getting headers to pass CARB E.O. tests is to make them out of stainless steel. Just that difference in retained heat can be enough to make the difference--issue being the O2 sensor and keeping the exhaust temps up until the gases pass that sensor.

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

We'll find out, I ordered a new Revolver yesterday and I will drop it off to the ceramic coaters along with my intake manifold as soon as it gets here. I'd like to see if my intake air temperature drops any.

- Location

- In a strange land

You will like how ceramic coating affects the intake.

I recommend, if you have the time, grind as much of the intake smooth as possible (the exterior--I am guessing you already have the interior port matched). At the very least, get rid of any rough casting seams.

I recommend, if you have the time, grind as much of the intake smooth as possible (the exterior--I am guessing you already have the interior port matched). At the very least, get rid of any rough casting seams.

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

Yep, that's the downside! Since my intake was ported and bored for the TB when Russ also did my head I have to pull my intake and wait to get it coated. I thought about calling Russ to see if he had one available that's already done with his work?

Yep, that's the downside! Since my intake was ported and bored for the TB when Russ also did my head I have to pull my intake and wait to get it coated. I thought about calling Russ to see if he had one available that's already done with his work?

I talked with Russ a few years back about porting and ceramic coating. He didn't do or offer ceramic coating at the time. The silver ceramic coat has lasted on the headers and an intake I have. I have not run the intake, but it has been outside for a long time. I would round or chamfer any edges. Sort of like paint, that is were it might flake off first. At least that is were it was on the Pace Setter headers I had. I did use Jet Coat on a set of headers. I don't see any issues with them. Might check around for people who do Power coatings. Some offer ceramic coatings.

Edit' Powder Coating'

Last edited:

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

Just wishful thinking so I could do the entire job in 1 day vs being down for a week. I've also got a set of Boostwerks Titanium studs on the way!

Just wishful thinking so I could do the entire job in 1 day vs being down for a week. I've also got a set of Boostwerks Titanium studs on the way!

Thanks for the update. I tired to order a set a few months back. I ordered two sets. Still, looking for the Fuel Pump setup they have.

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

I dropped off my new Revolver today at the coater's, I received it Friday and spent the weekend going over it inside and out with all my grinders. We'll see in couple of weeks!

WNC2000XJ

NAXJA Forum User

- Location

- Asheville NC

Update on the headers? i'm curious on the outcome and performance of them.

I dropped off my new Revolver today at the coater's, I received it Friday and spent the weekend going over it inside and out with all my grinders. We'll see in couple of weeks!

RCP Phx

NAXJA Forum User

- Location

- Phoenix,Az

Update on the headers? i'm curious on the outcome and performance of them.

https://naxja.org/forum/showthread.php?t=1162392

Similar threads

- Replies

- 4

- Views

- 389

- Replies

- 9

- Views

- 377

- Replies

- 18

- Views

- 1K