- Location

- Hammertown, USA

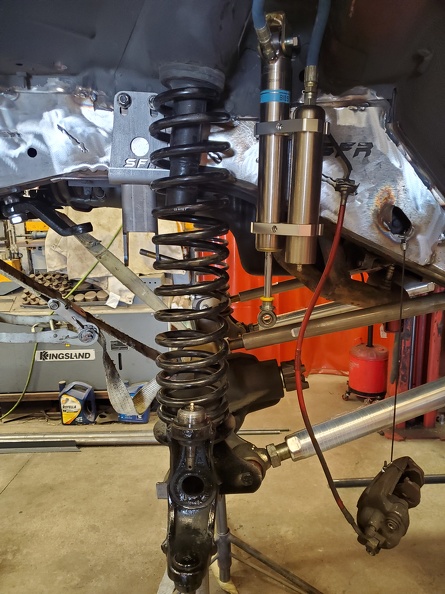

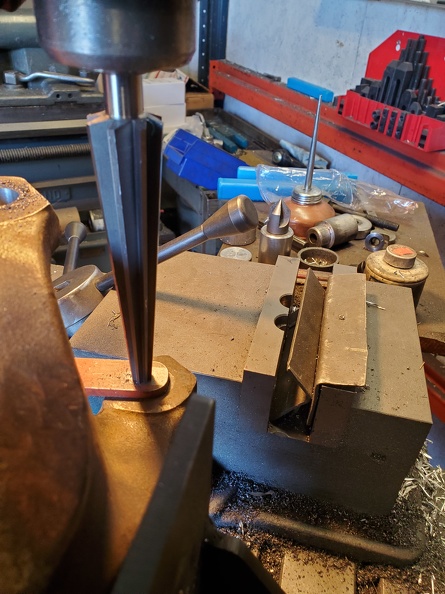

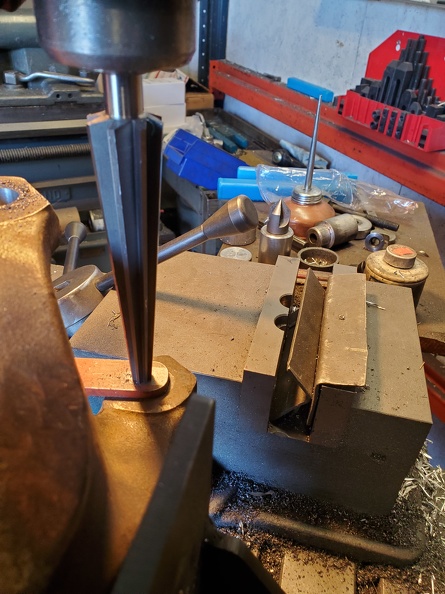

Dallas built a nice fixture for putting knuckles in the mill, which compared to using a hand drill does not suck at all.

He's able to pre-set the depth for TRE's and DRE's to get the taper correct. In this case we did the draglink hole a bit extra shallow which i'll cover later (but may be light on photos on).

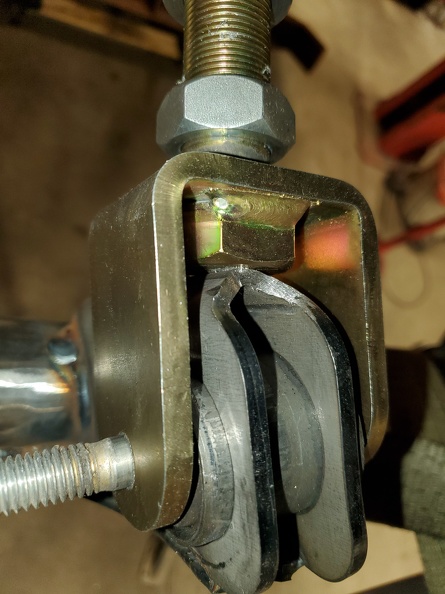

A spacer to set zero height

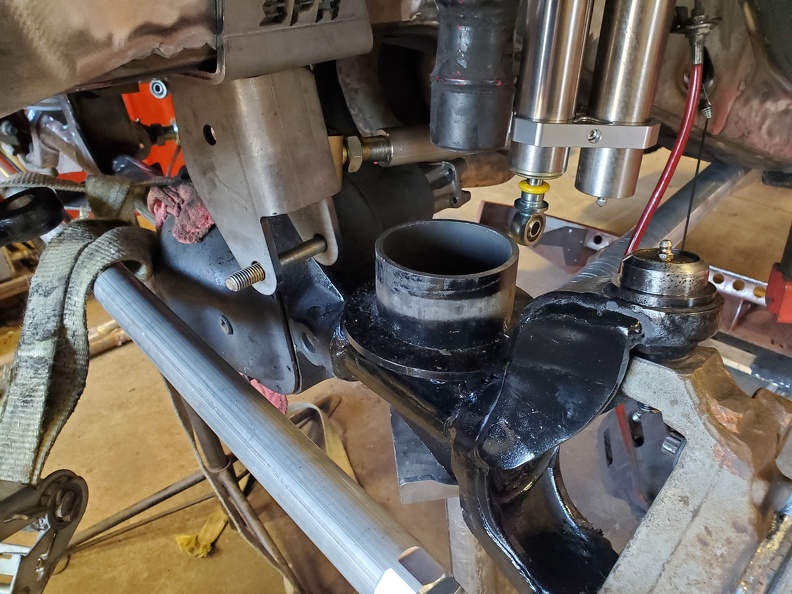

And then cut away.

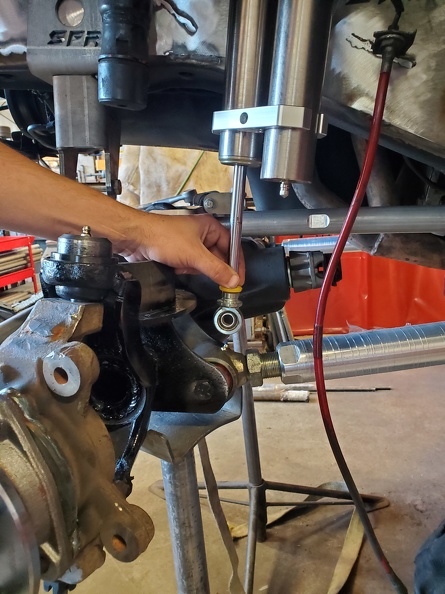

Finally bolt it into the car and see if things actually fit. I didn't get photos but we did the draglink end light the first cut and then cut a bit more - we didn't want to go too deep and have the nut get close to the tie rod. Turned out not to be a problem there is miles of room.

It looks snug but there should be plenty of room, this should do nicely.

He's able to pre-set the depth for TRE's and DRE's to get the taper correct. In this case we did the draglink hole a bit extra shallow which i'll cover later (but may be light on photos on).

A spacer to set zero height

And then cut away.

Finally bolt it into the car and see if things actually fit. I didn't get photos but we did the draglink end light the first cut and then cut a bit more - we didn't want to go too deep and have the nut get close to the tie rod. Turned out not to be a problem there is miles of room.

It looks snug but there should be plenty of room, this should do nicely.