So when we last left off, I had the car running, and home, but had fuel pressure issues still and some pinging under low RPM load.

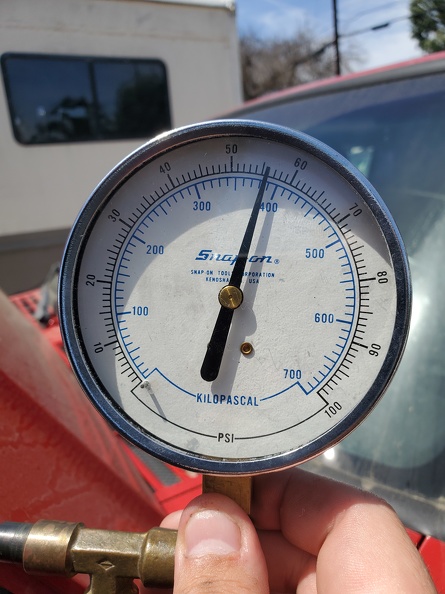

After replacing the fuel pump relay, I was getting super erratic fuel pressure readings. As it turns out, that was a combination of gauge problems, and the schrader in the NRT fuel rail being just a hair too deep in the fitting. If I pull the schrader out before hooked up a gauge each gauge gets a consistent reading, but I get very different readings on my HF and OTC gauges, which are different again from Chris Jenson's snap on gauge. I'm going to say the snap on is probably the most accurate, giving me 56 PSI. Inexplicably higher than the 49 PSI the new FPR should be giving me, but we're going to roll with it.

Chris Jensen from Christuned and our own Mark Nelson came by and wired the jeep up for diagnostics on Sunday. A digital fuel pressure gauge, a wide band o2 sensor, and OBD2 readings, all going into a data logger tied to Chris's laptop.

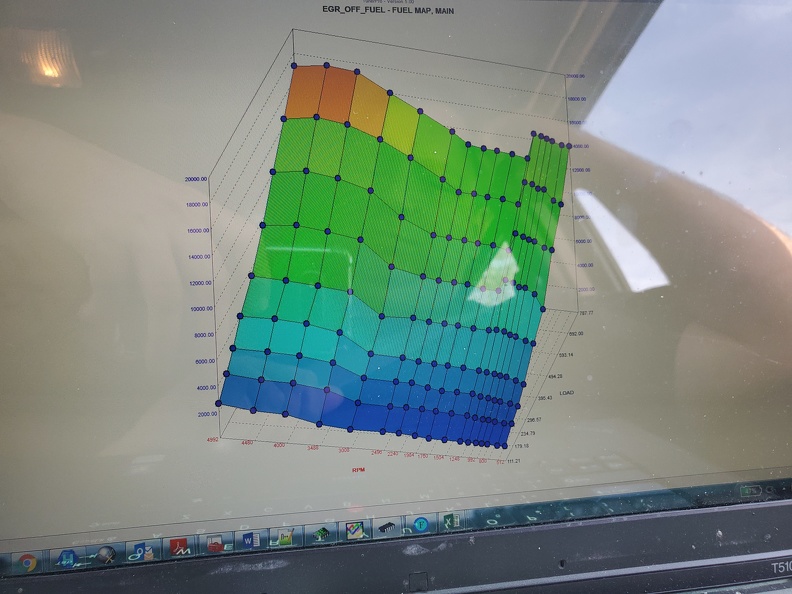

Not having ready access to a dyno on a Sunday, we used a local freeway on ramp to do hard WOT pulls, and then cruised to the next exit on light throttle to get more readings. Pretty fascinating stuff actually. I didn't take a lot of photos of Chris's work, but he built fuel and air maps to visualize what it is doing and made adjustments. This is the only map I photo'd, which was after the 1st adjustment.

I have no more photos of the process, but I'll talk about it.

At first the jeep at WOT was running so rich that it wouldn't register on the wideband o2. It took 3 tunes of trimming fuel before we could get good readings. With each adjustment the jeep got A LOT faster. About the 5th adjustment we started getting a good base, the low RPM pinging stopped but we started to get new pinging under WOT. I want to say we did 5 more ECU revisions, with each adding more pinging but did make us a lot faster, then Chris stepped us back a tune or two and added some more fuel under load, which stopped the pinging completely (but did take some power away). At the end of the day we ended up with near stock ignition timing and a lot less than stock fuel, but a bit more than Chris wanted to see.

He was able to tune the engine to running very well (and i'm super happy with it) but we did determine that maybe 11.4 is too much compression for a customer car. Russ and I are still talking about what to try next.

I'm sure I am forgetting things, but:

* Air/fuel map customized for my engine

* Timing adjusted to get the most bottom end and cut out pinging

* Aux fan set to come on at 180 so that it runs most of the time (my request)

* Idle bumped from 550 to 700 to smooth out idle vibration

* Threshold for misfire raised to limit the JTEC random misfire codes that haunt us

* Fast idle bumped from 1100 to 1300 (for future high idle switch addition)

Mark provided me with an SCT 9550 tuner which Chris loaded up with this tune, the factory tune, and a limp mode tune (-4 timing and add fuel) just in case I hurt the motor or get crappy gas while traveling.

Working with Chris was fascinating, and I learned a ton - mostly about how little I actually know.

We discussed how he works with other customers, and his frustration that customers often want a magical tune but won't spend a couple hundred bucks on the equipment required to do data logging, and expect him to dial it in based on engine specs. Why spend $4000 on a motor if you won't spend $300 to see what it is doing and tune it? He doesn't understand, (I do, XJ guys are cheap).

After going through this process, I can tell you that there is no way you could do this just off of engine specs, and anyone who is selling a tune that way is doing you a disservice. If you have a custom motor and want to get the most out of it, i HIGHLY suggest you contact Chris for a list of what diagnostic gear to buy (you'll spend about $350) and get him some data logging, and talk about doing a tune (i can't say what his services will cost, you have to ask him).

After they left I took a cranking compression reading off of the engine, and went back over everything. I have a slight trans cooler leak that I'm going to have to pull the airbox and aux fan to find, and I clocked the exhaust away from the oil pan and have a slight exhaust leak to adjust now.

I am super happy with how the car drives now. Now that I have it in the final config I'm debating regearing to 4.56, and I certainly need to install a shift kit in the trans.

A couple of other things of note:

* Chris suggested I try a 180* thermostat. Village wisdom tells us that the ECU won't like that, but I've been told it won't be a problem and may help combat pinging if I get crappy fuel.

* My intake air temp was MUCH lower than Chris expected and sees with most other jeep engines. He attributed that to the aFe intake, and suggests that becomes something we recommend to people going forward.