XJ_Vikings

NAXJA Forum User

- Location

- Simsbury, CT

So a little background to start.

Bought my jeep stock back in 2002 when i was 16, about 55k on it. After some casual wheeling I decided to throw on 30x9.50 BFG AT and then a year later decided to lift (I know, i was young and stupid). Didn't do any research on the lift, ended up with a garbage trailmaster, drop brackets, add a leaf etc. It still pains me to think about it.

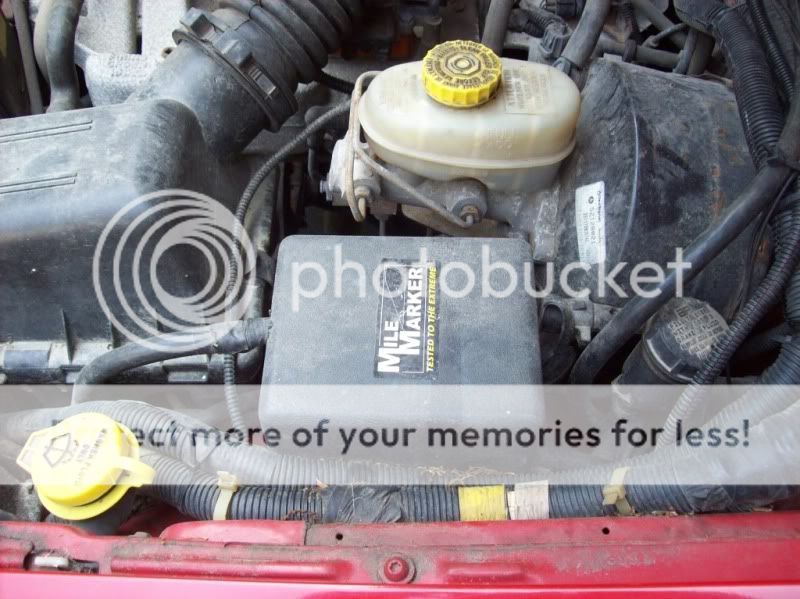

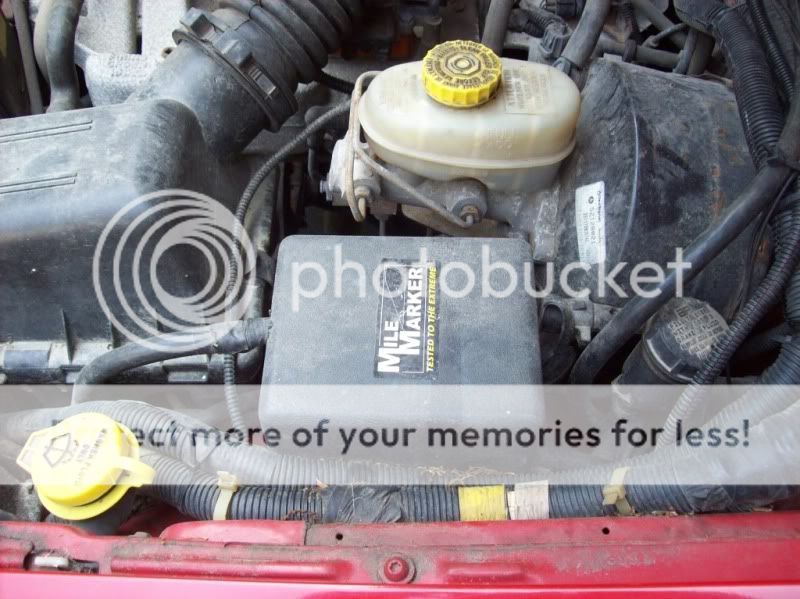

Didnt do too much on it except relocate the solenoid to the engine compartment and relocate the master on/off to the dash. Pretty happy with it however the wire was quite expensive. I upped the diameter to account for the increased resistance.

I started planning and researching everything I wanted to do back in 2006. However, a deployment and school made things go slowly. Before I left I decided to commit and take her off the road, buy a DD and start my work when i got back.

Heres the 2009 Honda i picked up last year

The jeep in its current state

Its been sitting in my garage for a couple years now. Only issues were a dead battery and a broken hood release.

Did some work on it today (first time in 3 years) and replaced the battery with an optima yellow top, and started the hood pin install.

Ive had a 44 sitting in my basement for about 4 years now, I did all the cleanup work a few years back, just been waiting to take it to CT Axle to finish it up, that's happening next week finally. The plan now is to get as much done for the rebirth as possible without immobilizing her. I don't want to deal with the Honda this winter so I'm getting the heep back in shape for a DD, then starting to throw everything on in the spring. Hopefully this thread keeps me motivated.

Heres what ive come up with in my years of research (while the other guys in Iraq were using their computer time to talk to their girlfriends, I was on )....

)....

Alcan rear leafs

Bilstein shocks

woody shaft

TnT 5.5 arms

not sure how much im going to put into the 30

4.56 gears, aussie in 44

not sure on tires yet... still

not at all worthy of advanced fab yet, being that it is neither advanced or fabricated, but itll be there in due time

the whole idea behind this is to use my age, wisdom, and engineering degree to do it the way i should have the first time.

Bought my jeep stock back in 2002 when i was 16, about 55k on it. After some casual wheeling I decided to throw on 30x9.50 BFG AT and then a year later decided to lift (I know, i was young and stupid). Didn't do any research on the lift, ended up with a garbage trailmaster, drop brackets, add a leaf etc. It still pains me to think about it.

Didnt do too much on it except relocate the solenoid to the engine compartment and relocate the master on/off to the dash. Pretty happy with it however the wire was quite expensive. I upped the diameter to account for the increased resistance.

I started planning and researching everything I wanted to do back in 2006. However, a deployment and school made things go slowly. Before I left I decided to commit and take her off the road, buy a DD and start my work when i got back.

Heres the 2009 Honda i picked up last year

The jeep in its current state

Its been sitting in my garage for a couple years now. Only issues were a dead battery and a broken hood release.

Did some work on it today (first time in 3 years) and replaced the battery with an optima yellow top, and started the hood pin install.

Ive had a 44 sitting in my basement for about 4 years now, I did all the cleanup work a few years back, just been waiting to take it to CT Axle to finish it up, that's happening next week finally. The plan now is to get as much done for the rebirth as possible without immobilizing her. I don't want to deal with the Honda this winter so I'm getting the heep back in shape for a DD, then starting to throw everything on in the spring. Hopefully this thread keeps me motivated.

Heres what ive come up with in my years of research (while the other guys in Iraq were using their computer time to talk to their girlfriends, I was on

)....

)....Alcan rear leafs

Bilstein shocks

woody shaft

TnT 5.5 arms

not sure how much im going to put into the 30

4.56 gears, aussie in 44

not sure on tires yet... still

not at all worthy of advanced fab yet, being that it is neither advanced or fabricated, but itll be there in due time

the whole idea behind this is to use my age, wisdom, and engineering degree to do it the way i should have the first time.

Last edited: