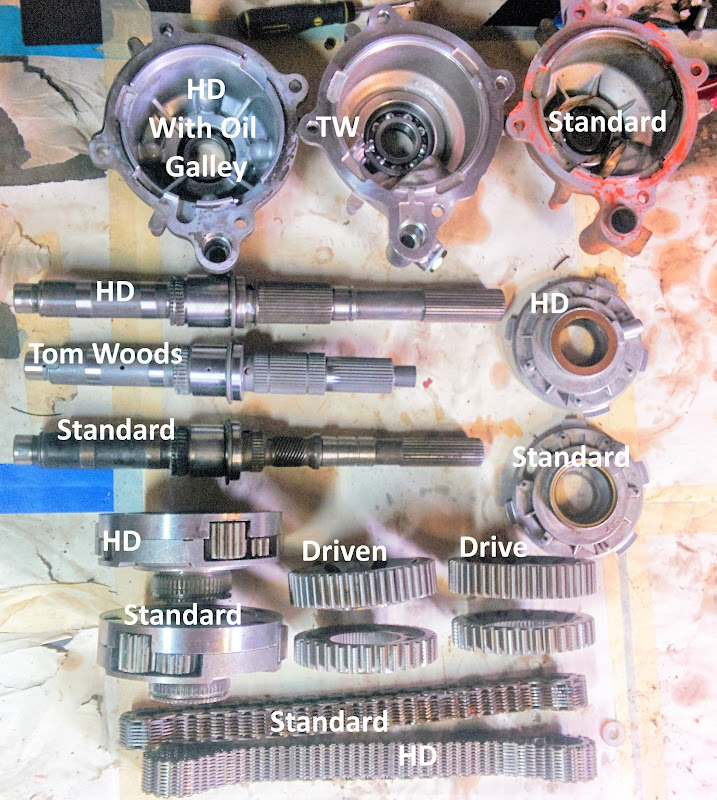

I am in the process of rebuilding a NP242. One think led to another, and I went from a hack and tap to buying a Tom Woods insane 32 spline super duper main shaft, so I figured, "what the heck, lets see if I can also do the 1.25" chain too!". I picked up a cheap NP242D out of a dorango today to see WHAT the differences were, since most of the internet was devoid of much tech about the 242HD. I am thinking that the differences are too much to make a NP242 LD with a 242HD chain.

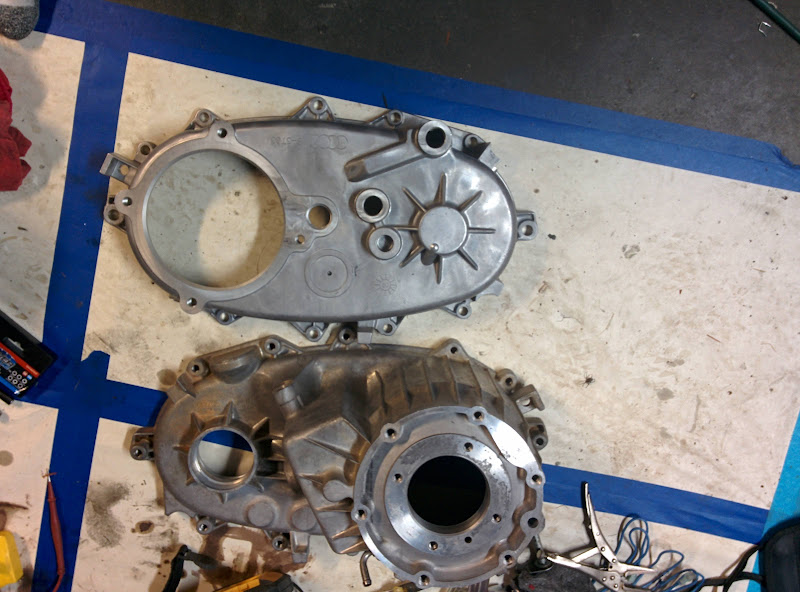

First I found that the rear half of the case was taller on the HD, and that the oil pump rides the main shaft via a snap ring and a bronze bushing instead of bottoming on the case and uses a lipped seal. The diameter of the shaft at the oil pump on the 242HD must be .25" smaller, so I can't use the HD pump on the LD shaft.

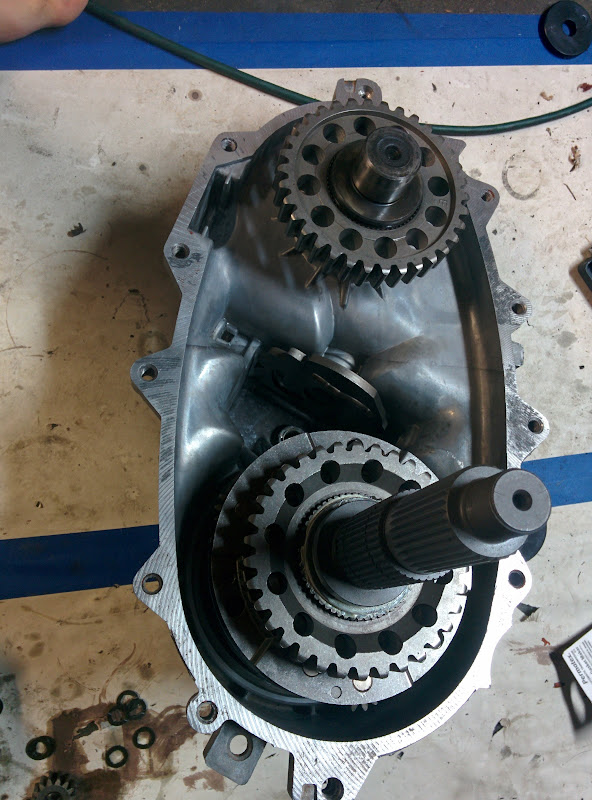

Next I removed all of the snap rings to remove the chain and found the bigger (1.25" from the HD) sprocket on the main shaft had an additional .25" of collar on the differential output.

When I found this, my plan was to use the Tom Woods shaft with the HD differential and 1.25" sprockets, along with the rear case from the HD. This was fine and dandy, but the collar that the differential's retaining snap ring was supposed to go into was .25" behind the differential... so I was now thinking I would get a friend with a lathe to machine the output of the differential to ride .25 over the collar on the main shaft, which was great till the oil pump came back into the equation. Not an option. the sprocket dragged on the oil pump, so thats not an option... so has anyone build a 1.25" chained NP242 with a Tom Woods main shaft? Is the .25 of extra chain worth what it would take to get it all to fit?

Here's some pictures to demonstrate my conundrum.

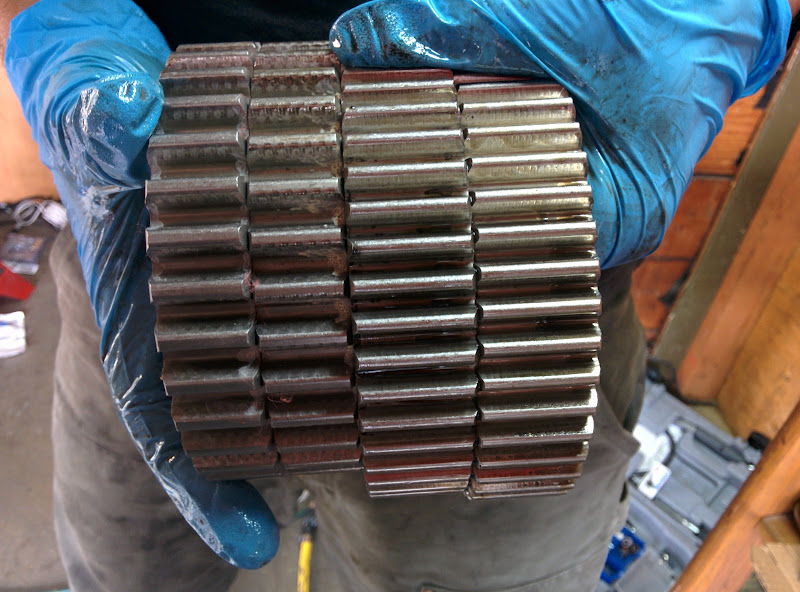

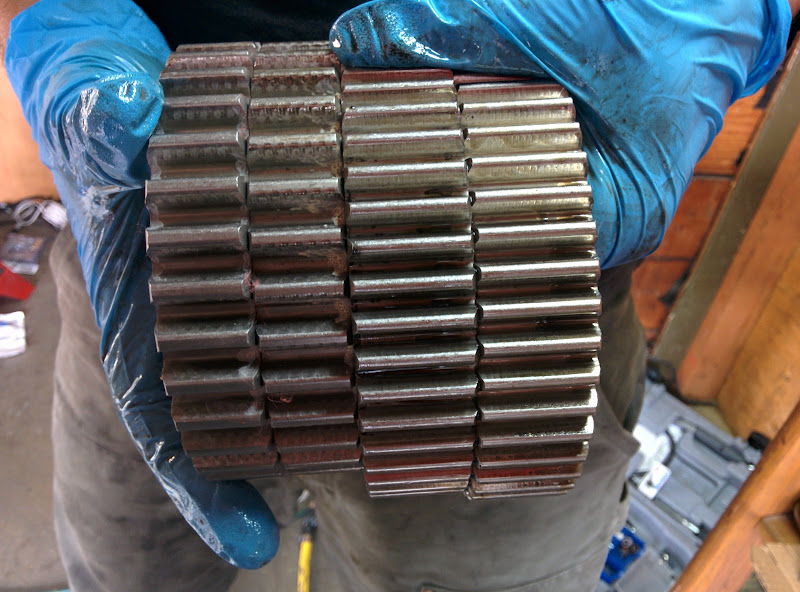

The gears are substantially different by width, diameter and tooth count, but has the same splines.

Differences in the differential.

Honestly, the 242HD shaft doesn't look as strong as the 242 Tom Woods shaft, it necks down at the output. Because of this, you could only re spline it for a smaller 27 splines.

It looks like the .25" is gained by lengthening the bearing race, and moving the rest of the gear train .25" towards the rear of the case.

This doesn't even go into how much difference there is in the differences in the tail housing.

ehall, I am sure you will see this, I saw on your build thread that you were going to build a 242HD, what was your plan?

The stuff I have got to work, was a 32 spline front output and a 6 pinion low range (I already had one).

First I found that the rear half of the case was taller on the HD, and that the oil pump rides the main shaft via a snap ring and a bronze bushing instead of bottoming on the case and uses a lipped seal. The diameter of the shaft at the oil pump on the 242HD must be .25" smaller, so I can't use the HD pump on the LD shaft.

Next I removed all of the snap rings to remove the chain and found the bigger (1.25" from the HD) sprocket on the main shaft had an additional .25" of collar on the differential output.

When I found this, my plan was to use the Tom Woods shaft with the HD differential and 1.25" sprockets, along with the rear case from the HD. This was fine and dandy, but the collar that the differential's retaining snap ring was supposed to go into was .25" behind the differential... so I was now thinking I would get a friend with a lathe to machine the output of the differential to ride .25 over the collar on the main shaft, which was great till the oil pump came back into the equation. Not an option. the sprocket dragged on the oil pump, so thats not an option... so has anyone build a 1.25" chained NP242 with a Tom Woods main shaft? Is the .25 of extra chain worth what it would take to get it all to fit?

Here's some pictures to demonstrate my conundrum.

The gears are substantially different by width, diameter and tooth count, but has the same splines.

Differences in the differential.

Honestly, the 242HD shaft doesn't look as strong as the 242 Tom Woods shaft, it necks down at the output. Because of this, you could only re spline it for a smaller 27 splines.

It looks like the .25" is gained by lengthening the bearing race, and moving the rest of the gear train .25" towards the rear of the case.

This doesn't even go into how much difference there is in the differences in the tail housing.

ehall, I am sure you will see this, I saw on your build thread that you were going to build a 242HD, what was your plan?

The stuff I have got to work, was a 32 spline front output and a 6 pinion low range (I already had one).