5-90

NAXJA Forum User

- Location

- Hammerspace

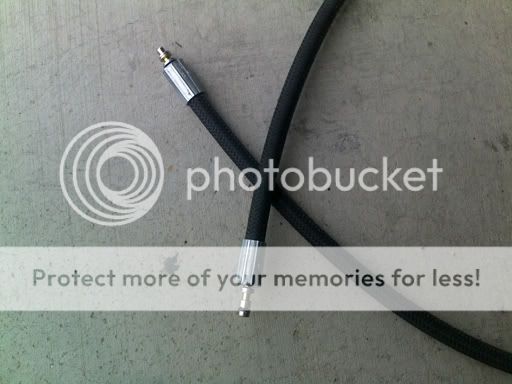

"Clutch Kit" = Clutch disc, pressure plate, T/O bearing (or internal slave,) and pilot bearing/bushing all in one box. Last time I had to deal with a failed internal slave (yech!) it was $100 for the slave or $140 for the clutch kit. I just sprung for the kit - even though I didn't need it, I was already there (and I felt better when I was done.)

There isn't an "overhaul kit" for that asinie internal slave cylinder (concentric slave cylinder, or whatever they're calling the wretched thing this week...) so the only service is replacement. The master cylinder may be overhauled, as you've already found out.

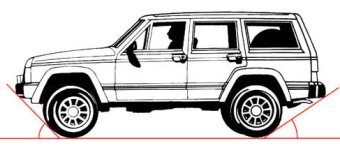

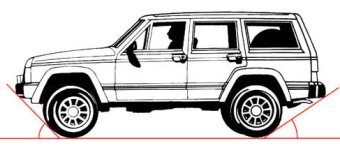

You've heard of "approach angle" and "departure angle," right?

Approach angle is the angle of terrain (measured from a horizontal ground line,) with the specification being the angle where the front bumper will hit the ground before you can start your tyres up it.

Departure angle is the same thing, only turned around. It's the angle at which the rear bumper will hang up before the rear wheels will engage the ground line.

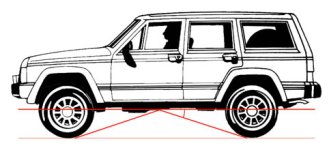

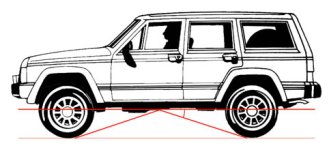

"Breakover angle" is related to high-centering. Taken theoretically, the "breakover angle" is the angle between sides of a point at which the vehicle will lose contact between one end or the other and the ground, once it crests the peak.

The first image illustrates the approach and departure angle limitations, while the second will show the breakover angle limitation. Try to transit an angle greater than breakover (or an obstacle - it need not be an angular problem, just apply some trigonometry to see the headache...)

Using trig to figure the approach and departure angles is easy - for the breakover angle, you'll need to measure the lowest point of the underbody, and the longer of the two distances between that point and an axle. The "lowest point" is a dead vertical measurment, while the "longer distance to the axle" is a dead horizontal. You get a right triangle from those two figures (the legs - the hypotenuse is not needed for this one,) and you can then figure the angle using the Sine ratio.

Why the longer of the two along the ground line? Because that's going to give you the shallower angle (a "quick and dirty" method is to simply measure the actual wheelbase - from the axis of revolution of one axle to the other - and then measure the height of the frame rail at the midpoint of that line. You'll probably have points that are lower, but I told you it was "quick and dirty...")

There isn't an "overhaul kit" for that asinie internal slave cylinder (concentric slave cylinder, or whatever they're calling the wretched thing this week...) so the only service is replacement. The master cylinder may be overhauled, as you've already found out.

You've heard of "approach angle" and "departure angle," right?

Approach angle is the angle of terrain (measured from a horizontal ground line,) with the specification being the angle where the front bumper will hit the ground before you can start your tyres up it.

Departure angle is the same thing, only turned around. It's the angle at which the rear bumper will hang up before the rear wheels will engage the ground line.

"Breakover angle" is related to high-centering. Taken theoretically, the "breakover angle" is the angle between sides of a point at which the vehicle will lose contact between one end or the other and the ground, once it crests the peak.

The first image illustrates the approach and departure angle limitations, while the second will show the breakover angle limitation. Try to transit an angle greater than breakover (or an obstacle - it need not be an angular problem, just apply some trigonometry to see the headache...)

Using trig to figure the approach and departure angles is easy - for the breakover angle, you'll need to measure the lowest point of the underbody, and the longer of the two distances between that point and an axle. The "lowest point" is a dead vertical measurment, while the "longer distance to the axle" is a dead horizontal. You get a right triangle from those two figures (the legs - the hypotenuse is not needed for this one,) and you can then figure the angle using the Sine ratio.

Why the longer of the two along the ground line? Because that's going to give you the shallower angle (a "quick and dirty" method is to simply measure the actual wheelbase - from the axis of revolution of one axle to the other - and then measure the height of the frame rail at the midpoint of that line. You'll probably have points that are lower, but I told you it was "quick and dirty...")

!

!