- Location

- Wasatch Range

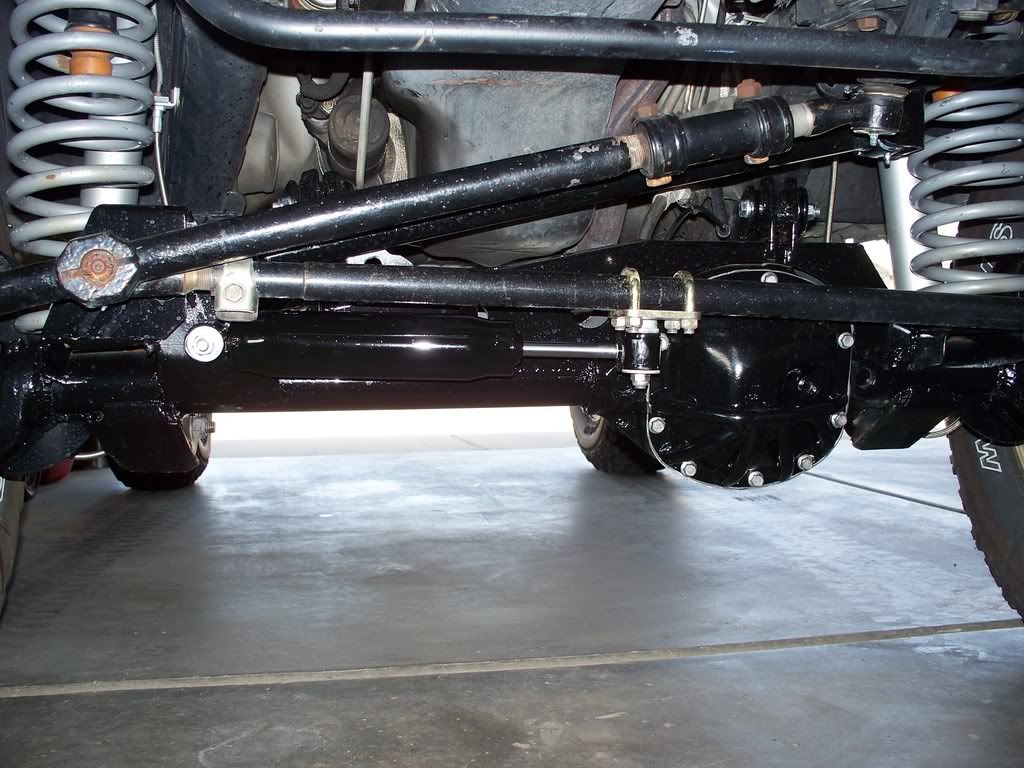

Thanks, it's like night and day.........

XJEEPER said:I agree with you though, Lincoln shows signs of retardation.........

What a horrible place for a steering stabilizer.....That retard Lincoln put his hydro ram there too.

Yup, 3 years ago.......and the WJ knuckle swap eliminated the need for a stabilizer, fwiw.

http://www.naxja.net/forum/showthread.php?t=913774&highlight=xj+buildup+III&page=7

OK, I realize this is an old thread but since there is some renewed interest in this subject I have a question. I plan to strip the axle tubes of all bracketry and cut the tubes in the middle, use internal sleeves and rotate the pumpkin to correct pinion angle. Then I will reinstall new bracketry on the axle. The reason for this approach is that it will ensure the knuckles remain square to the axle tubes. Has anyone tried this approach and if so what do I need to look out for? I have taken into consideration leaving room for the axle tube seal when installing the sleeves.

The only reason to sleeve it is to ensure the tubes go back together square. It will receive a custom truss for rigidity.I have heard of it done before.

What do you wish to acheive by sleeving it? Are you concerned about it being 1/4"?

A properly built truss would increase stiffness far more than sleeving it.

The only reason to sleeve it is to ensure the tubes go back together square. It will receive a custom truss for rigidity.

X500The fit is so tight that you shouldn't have a problem with the C staying square to the tube. After grinding/cutting off the factory weld, I had to beat on them pretty good to get them to rotate. At least that's what I remember when i did mine.

OK, I realize this is an old thread but since there is some renewed interest in this subject I have a question. I plan to strip the axle tubes of all bracketry and cut the tubes in the middle, use internal sleeves and rotate the pumpkin to correct pinion angle. Then I will reinstall new bracketry on the axle. The reason for this approach is that it will ensure the knuckles remain square to the axle tubes. Has anyone tried this approach and if so what do I need to look out for? I have taken into consideration leaving room for the axle tube seal when installing the sleeves.

I just feel that its possible to get the knuckle out of square with the tube, even though it is a tight fit the tube only goes 1 1/2" or so into the knuckle.Not sure I'm following your reasoning.....if you follow the procedure, how can the inner C get out of square with the tubes? I can see the logic behind sleeving for strength, but it's much more work than a truss.