magimerlin

NAXJA Forum User

- Location

- Flatonia, Tx

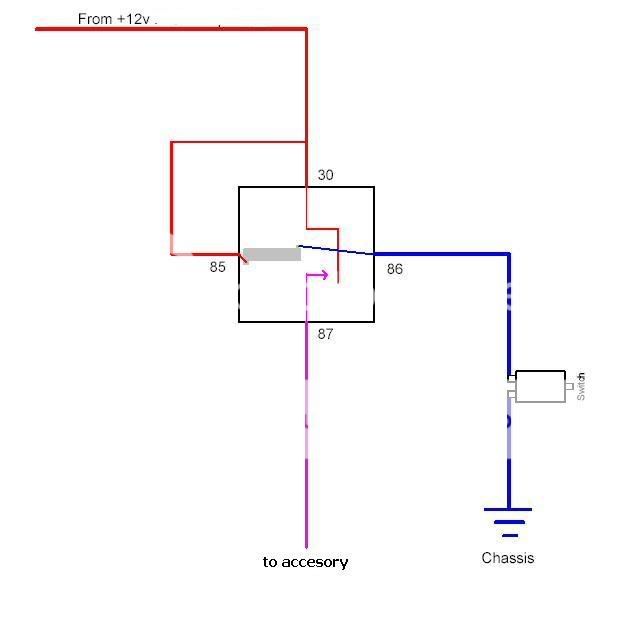

lost track of how many times I have posted this pic. I ALWAYS do neg tripped relays when ever I need any switches wired up. I have melted to many GOOD/PROPER sized switches running power through them, yes it happens even with the correct wiring and fuse set up. Most switches are not meant to carry the amp load for a continued amount of time, no matter what is printed on them.

When you have a switch that melts and starts a fire you will understand, but until then keep doing what y'all want. Me I will always wire neg trip relays. I have had one small fire that I thankfully caught and melted a few switches as well. And YES these where set up the correct way for a positive trip relay and where NOT overloaded by any means. Amps is what causes the heat so keep that in mind as well.

As far as a short goes..in a relay style setup from the switch side... If you short a positive wire to ground you get what? Yup you guessed it you burn crap. Basically make yourself a little welder. Try this test. Take a length of wire and hook one side up to the pos side of a battery charger and the other to the neg side of the battery charger. Now turn it on for just a sec or two and see what happens to that wire. I bet the wires insulation goes up in smoke or gets very hot. That's how fast the amperage can destroy a wire when under load. When you short a ground what do you get? Yup the accessory turns on but no welder like action, and no wire going up in smoke to potentially case a fire and or loose of the vehicle.

The negative vs. positive trip relay argument is as old as the Chevy vs. Ford debate. So no one will win as we all agree we feel our own way is better because we have had no issues with the way we do it now so why change. But that's OK each to there own.

OK Ok OK now for that pic might be easier to follow then the OP's paint doctored pic... simple and to the point

Oh even though it is not in the pic never forget to use the correct size fuse on the +12v source before the relay

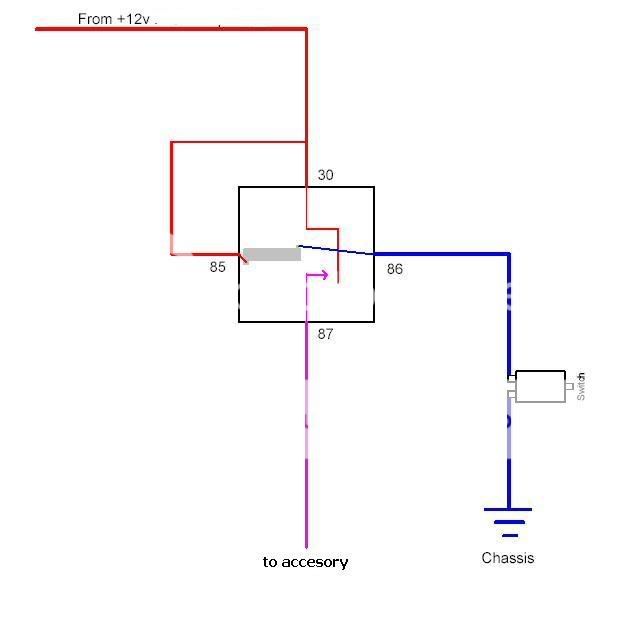

When you have a switch that melts and starts a fire you will understand, but until then keep doing what y'all want. Me I will always wire neg trip relays. I have had one small fire that I thankfully caught and melted a few switches as well. And YES these where set up the correct way for a positive trip relay and where NOT overloaded by any means. Amps is what causes the heat so keep that in mind as well.

As far as a short goes..in a relay style setup from the switch side... If you short a positive wire to ground you get what? Yup you guessed it you burn crap. Basically make yourself a little welder. Try this test. Take a length of wire and hook one side up to the pos side of a battery charger and the other to the neg side of the battery charger. Now turn it on for just a sec or two and see what happens to that wire. I bet the wires insulation goes up in smoke or gets very hot. That's how fast the amperage can destroy a wire when under load. When you short a ground what do you get? Yup the accessory turns on but no welder like action, and no wire going up in smoke to potentially case a fire and or loose of the vehicle.

The negative vs. positive trip relay argument is as old as the Chevy vs. Ford debate. So no one will win as we all agree we feel our own way is better because we have had no issues with the way we do it now so why change. But that's OK each to there own.

OK Ok OK now for that pic might be easier to follow then the OP's paint doctored pic... simple and to the point

Oh even though it is not in the pic never forget to use the correct size fuse on the +12v source before the relay