Alexia

NAXJA Forum User

- Location

- Huntsville, AL

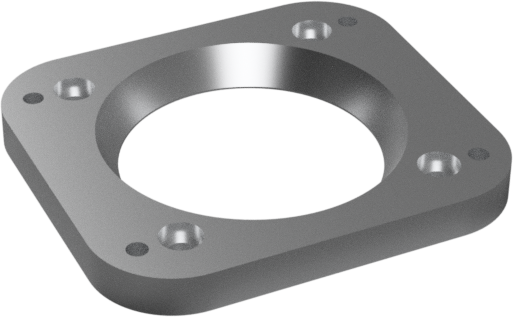

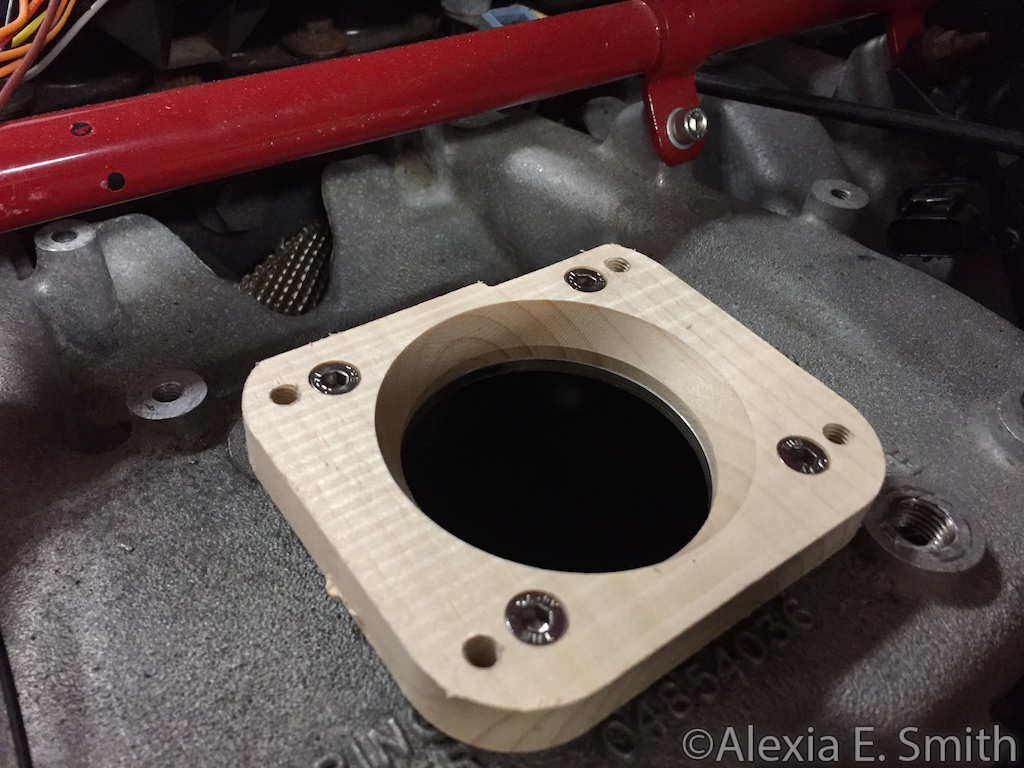

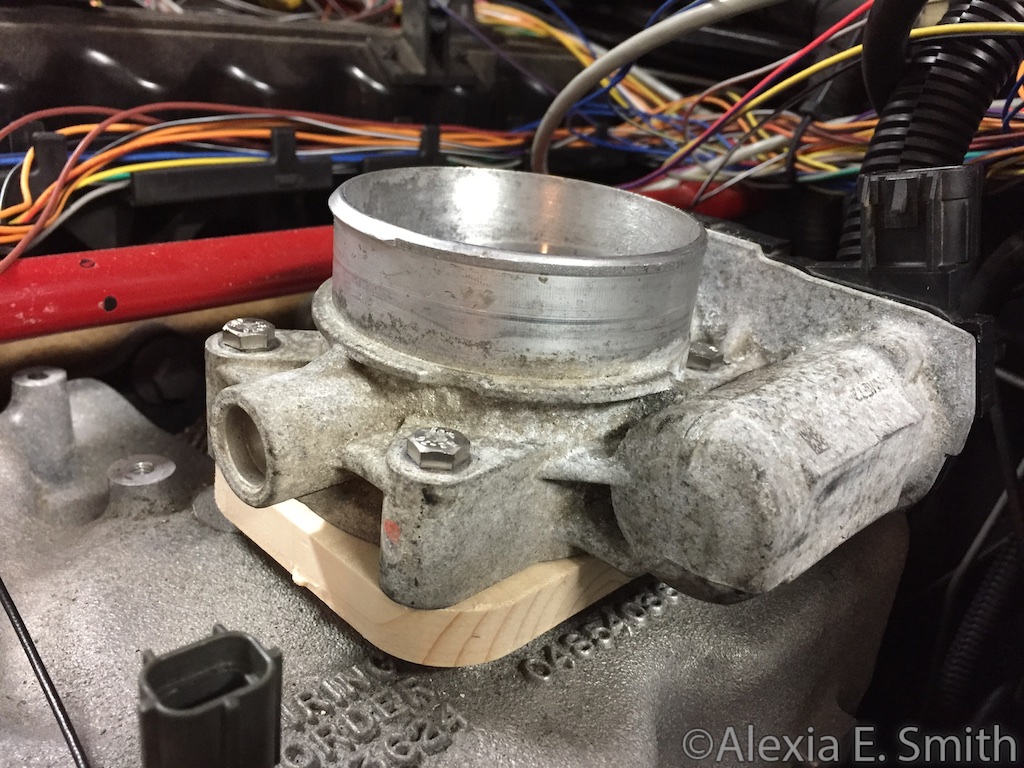

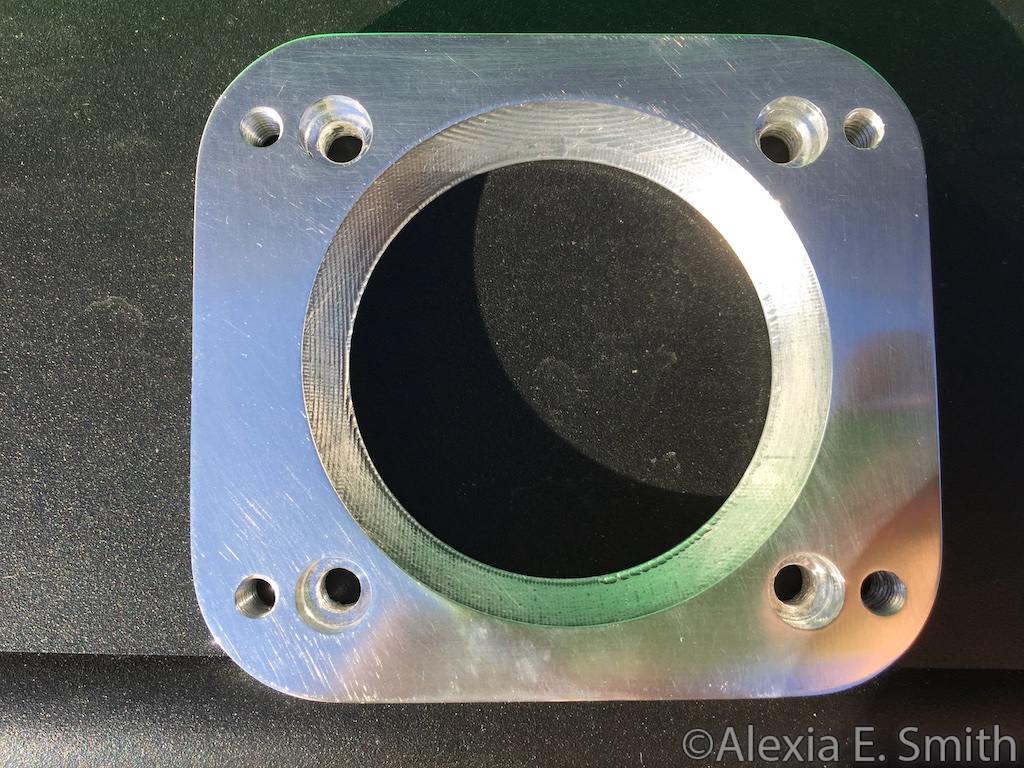

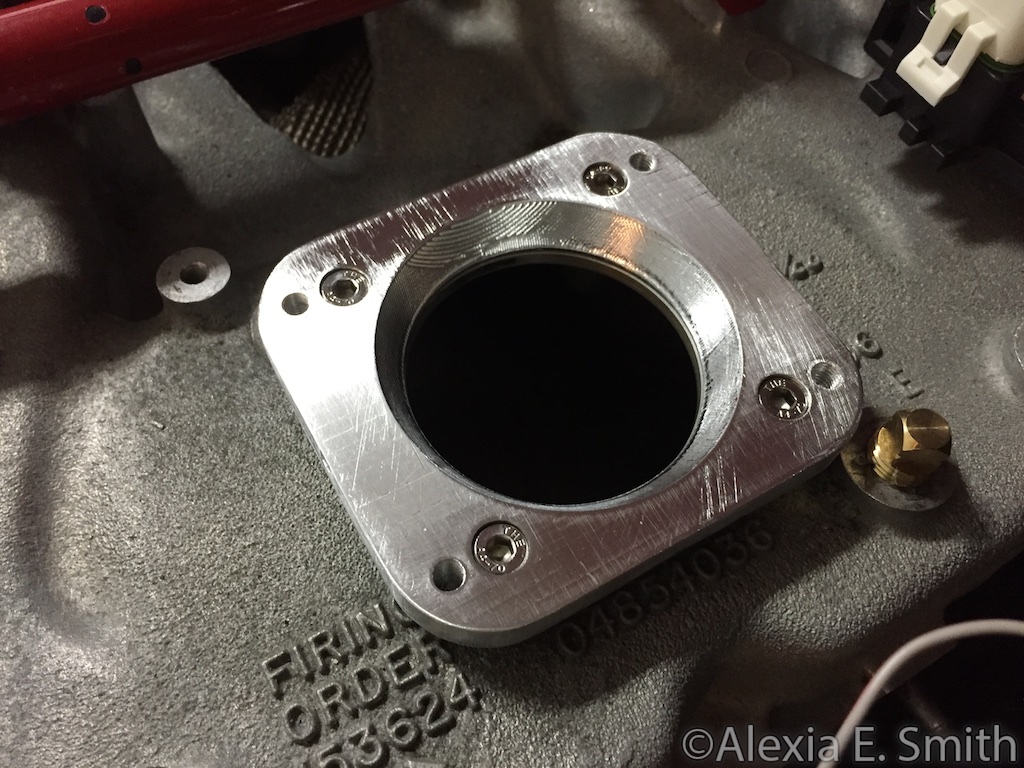

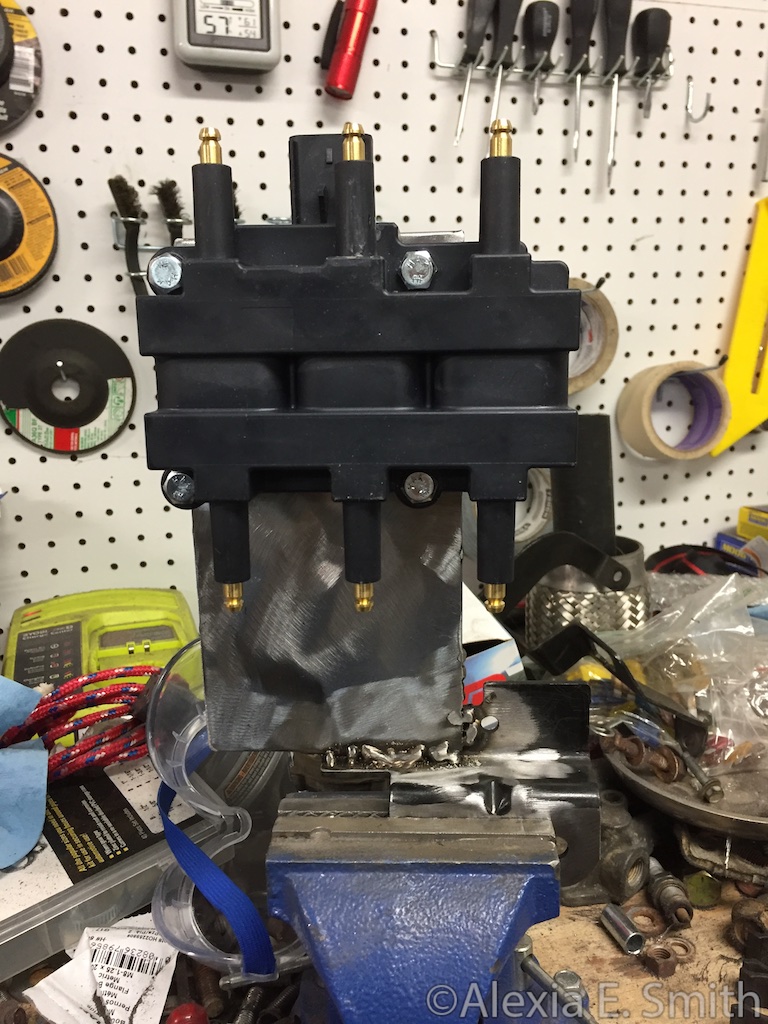

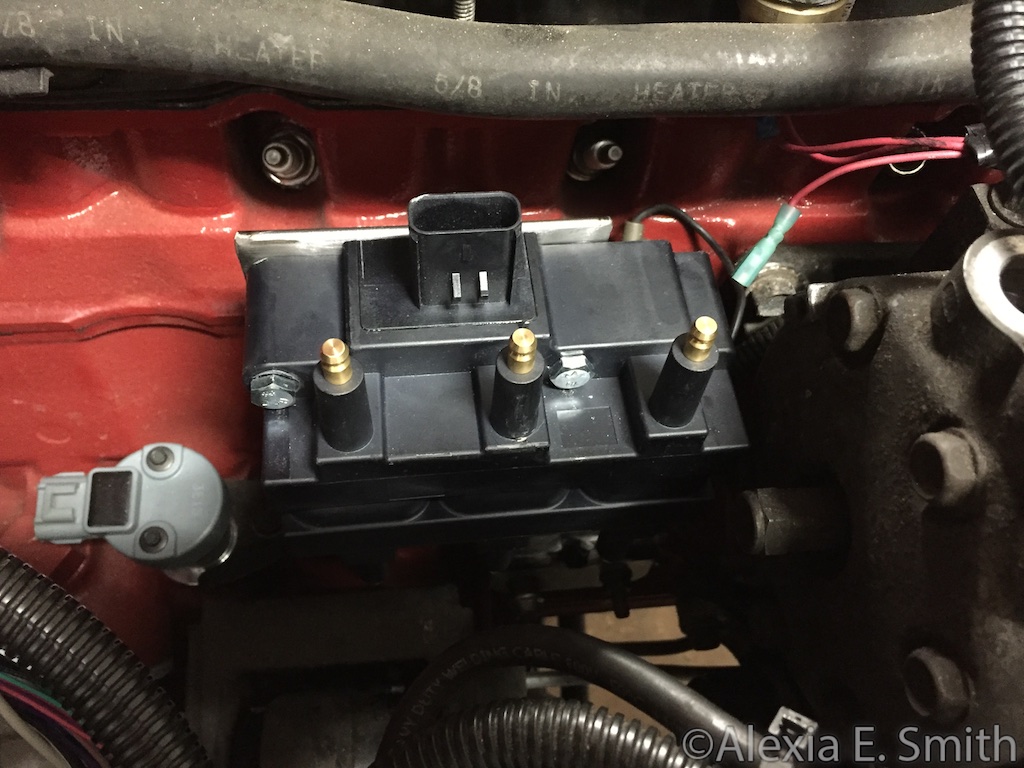

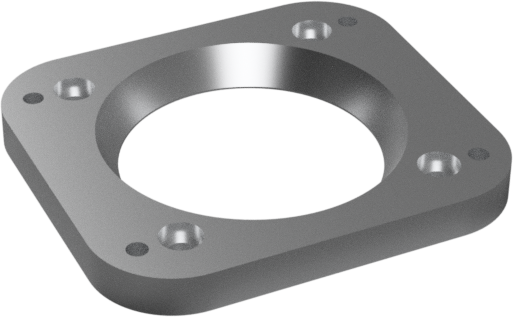

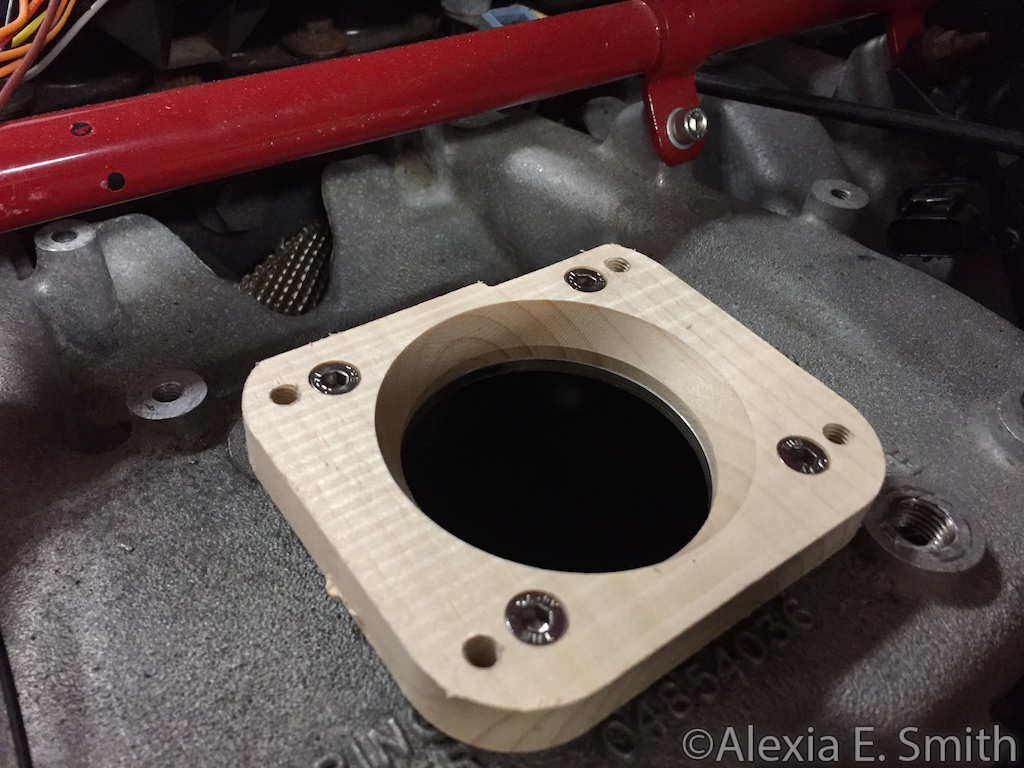

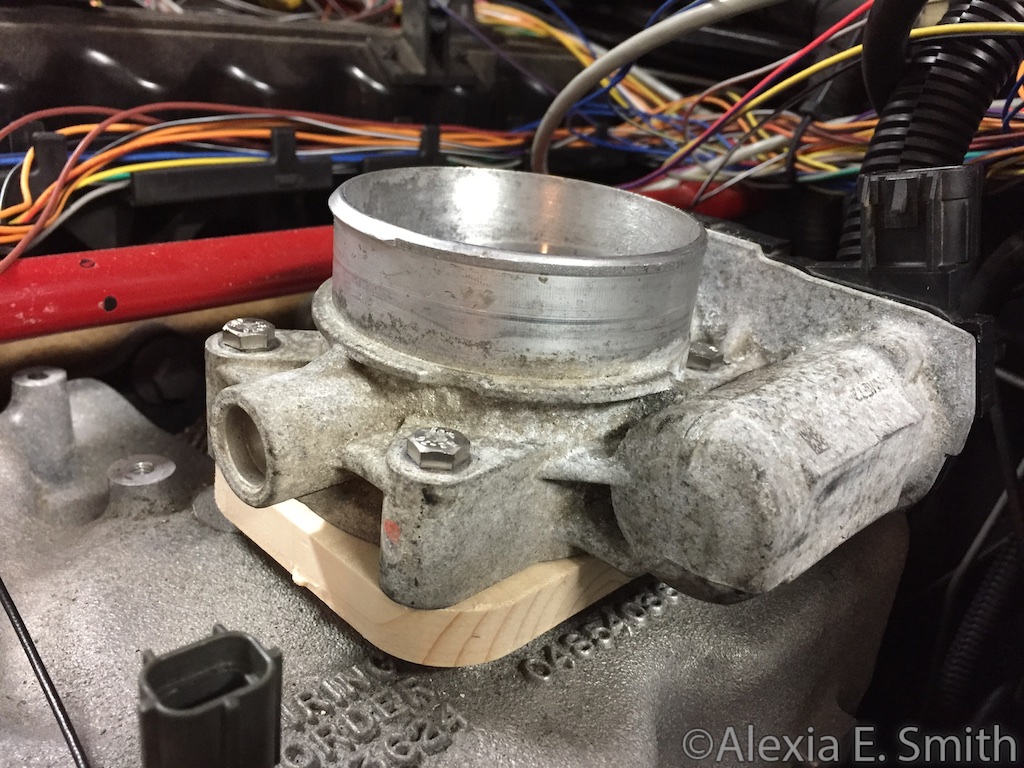

I started to install a Haltech ECU so I could do actual tuning instead of screwing around with useless JTEC PCM tuning. Since the Haltech supports drive-by-wire(DBW) I decided to try fitting a GM DBW throttle body on a stock manifold.

The only draw back so far is that I will have to relocate the valve cover vacuum line to a spare port on the side of the intake manifold. All the other rotations resulted in much worse fitment problems.

The only draw back so far is that I will have to relocate the valve cover vacuum line to a spare port on the side of the intake manifold. All the other rotations resulted in much worse fitment problems.