You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Convertible XJ project

- Thread starter IslanderXJ

- Start date

ghettocruiser

NAXJA Forum User

- Location

- Norristown, PA

Rev: Hope you dont mind me posting this pic. I found it awhile back in another post about TJ flares. I kind of dig the look of this. Not sure if its yours...if it is, was that top tight? removable? rear window?

Justin

Justin

I have spent alot of time looking at the stock body while hacking my rig to pieces. Some observations that might help you out:

Tying the cage B-pillar into the stock B-pillar, and still being able to get the doors to seal is going to be tricky (for the hardtop version). The softtop will basically eliminate this problem, though the top itself will be horribly complicated to produce.

If you are going to have a hoop (or overhead bar depending on your design) in the same plane fore and aft as the stock b-pillar, that overhead bar will be right above your head, and very close (it was too close for my tastes). It will definitely be too far forward for diagonal bracing in the same plane.

For the C-pillar, the same basic observations apply, except you also need to consider that your pillar will terminate at the inner fender - not really an ideal tie-in point.

But dont let any of that keep you from doing it. Figure it out, build it, and make sure to take alot of pictures.

Travis

Tying the cage B-pillar into the stock B-pillar, and still being able to get the doors to seal is going to be tricky (for the hardtop version). The softtop will basically eliminate this problem, though the top itself will be horribly complicated to produce.

If you are going to have a hoop (or overhead bar depending on your design) in the same plane fore and aft as the stock b-pillar, that overhead bar will be right above your head, and very close (it was too close for my tastes). It will definitely be too far forward for diagonal bracing in the same plane.

For the C-pillar, the same basic observations apply, except you also need to consider that your pillar will terminate at the inner fender - not really an ideal tie-in point.

But dont let any of that keep you from doing it. Figure it out, build it, and make sure to take alot of pictures.

Travis

IslanderXJ

NAXJA Forum User

- Location

- Avalon and San Luis Obispo

ghettocruiser- no thats not mine, haven't built mine yet

JLane99XJ- Your just jealous that your to dumb to build or even come up with anything like this

Zebaru- thanks for the help, I might have to do so modification then or just move it back a bit,

as for the C-pillar I was kinda shooting for going down through that part of the body all the way to the "frame"

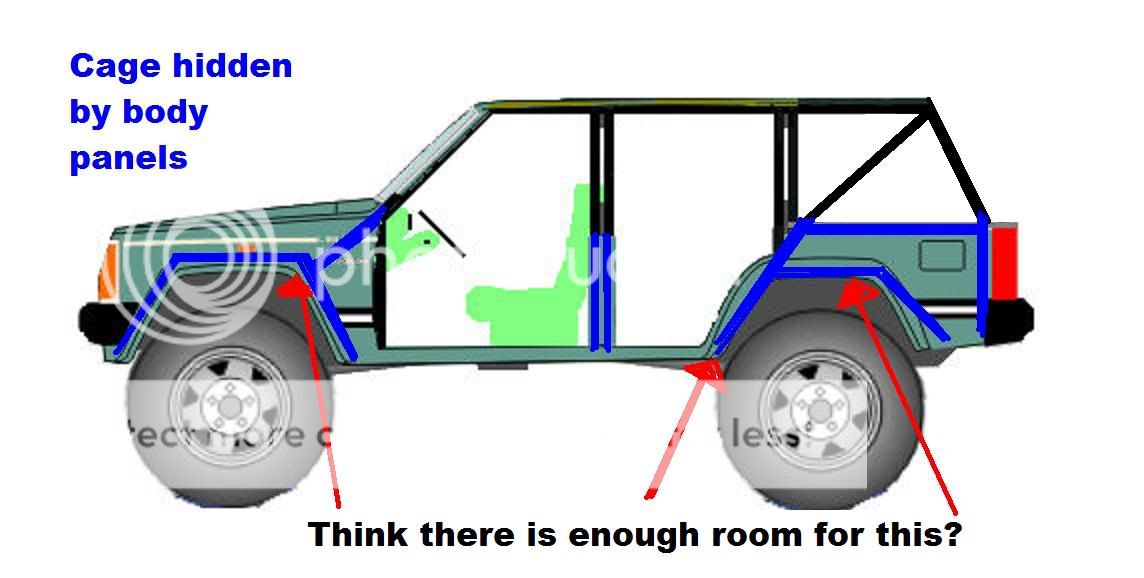

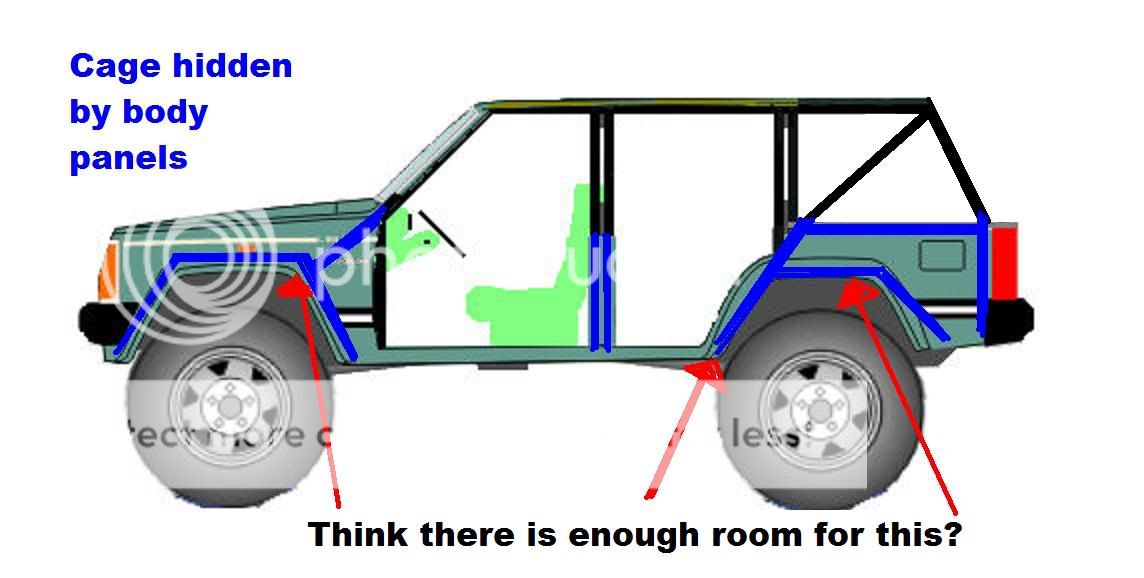

take a look at this

good idea/bad idea?

yeah not loking forward to the doors but i will figure it out

JLane99XJ- Your just jealous that your to dumb to build or even come up with anything like this

Zebaru- thanks for the help, I might have to do so modification then or just move it back a bit,

as for the C-pillar I was kinda shooting for going down through that part of the body all the way to the "frame"

take a look at this

good idea/bad idea?

yeah not loking forward to the doors but i will figure it out

I was actually talking about the pillar behind the rear seats. Without a rear seat, it would be easier, since you could just bend tube in or gusset over to the 'frame' (I assume you are plating or boxing that somehow as well?) Maybe a pair of buckets would make it not such a big deal?

The hoop at the very back will end up coming down right near the shackle mount area if you stay inside the existing sheet metal, which isn't that bad. It will be easy to reinforce that area and basically tie back into the frame. If you plan to come in right inside the outer skin, you will have to get a little more creative. In that case, I would think that trimming your rear quarters up to the body line might make it easier to fab up the necessary ties. It can be done without it, but working in that cramped area from the inside will suck.

There is a ton of info here and on pirate on cages in general and connection details. The cage info wont be as much help since you are basically building a cage like nobody else. The connection details however will be very relevant.

Travis

The hoop at the very back will end up coming down right near the shackle mount area if you stay inside the existing sheet metal, which isn't that bad. It will be easy to reinforce that area and basically tie back into the frame. If you plan to come in right inside the outer skin, you will have to get a little more creative. In that case, I would think that trimming your rear quarters up to the body line might make it easier to fab up the necessary ties. It can be done without it, but working in that cramped area from the inside will suck.

There is a ton of info here and on pirate on cages in general and connection details. The cage info wont be as much help since you are basically building a cage like nobody else. The connection details however will be very relevant.

Travis

IslanderXJ

NAXJA Forum User

- Location

- Avalon and San Luis Obispo

I was thinking about running some tube in the corner of the interior fender well, like when you look in the cargo area, just under the carpet/plastic.

I think I'm going to have to "adjust' the doors to fit right but, I don't mind the work, I had to do worse with less. Not looking forward to explaining the soft top design to the Marine top guys is going to suck, anybody know a cheap place?

I think I'm going to have to "adjust' the doors to fit right but, I don't mind the work, I had to do worse with less. Not looking forward to explaining the soft top design to the Marine top guys is going to suck, anybody know a cheap place?

IslanderXJ

NAXJA Forum User

- Location

- Avalon and San Luis Obispo

Heres a crappy top view of if, did it in paint , isn't it perty?

I got the general idea from rock hard 4x4 Part's XJ cage

http://www.rockhard4x4parts.com/xj-84.html

I got the general idea from rock hard 4x4 Part's XJ cage

http://www.rockhard4x4parts.com/xj-84.html

IslanderXJ

NAXJA Forum User

- Location

- Avalon and San Luis Obispo

Rev Den

NAXJA Forum User

- Location

- Plainfield, IL

ghettocruiser said:Rev: Hope you dont mind me posting this pic. I found it awhile back in another post about TJ flares. I kind of dig the look of this. Not sure if its yours...if it is, was that top tight? removable? rear window?

Justin

Yup...thats mine.

Top is weather tight.

Removable

And has a rear window.

AND

By far the most expensive part of the whole project.

Rev

IslanderXJ

NAXJA Forum User

- Location

- Avalon and San Luis Obispo

Great guess that this money pit is just going to get deeper, freaking super!

MOOSE16285

NAXJA Forum User

- Location

- Memphis, TN

That's a mighty advanced drafting program. Must have costed a bunch of money! What is it? MS Paint?

IslanderXJ

NAXJA Forum User

- Location

- Avalon and San Luis Obispo

All of the pictures except the topview of the cage on #27 (yep, MS paint) were on Jasc Paint Shop Pro Studio, just another expert piece of software to get the point across, lol. I was trying to us AutoCAD 2006, but I didn't exactly know how to use it. Anybody know where I could get a quite a bit simpler drafting program?

Great topic... IslanderXJ... I am in the process of doing almost exactly what your pics show with making the top removeable. I already finished the cage that has the tubing embedded into the sheetmetal ABCD pillars so the unibody should be good to go with the top off. Bracing all the pillars is critical if you want functioning doors.

The next task is to build a exo/rack to support the roof section when it comes off. If you want that top to fit back on it needs to be reinforced.

I pretty much decided on having a full and half set of doors to keep things sealed up in the winter but also to have a set that is cut down as much as possible with the top off. Modding the hinges should make swaps pretty simple.

Heres some pics of my cage... more to come with the top chopping...

http://community.webshots.com/album/142616888gPMNvD

The next task is to build a exo/rack to support the roof section when it comes off. If you want that top to fit back on it needs to be reinforced.

I pretty much decided on having a full and half set of doors to keep things sealed up in the winter but also to have a set that is cut down as much as possible with the top off. Modding the hinges should make swaps pretty simple.

Heres some pics of my cage... more to come with the top chopping...

http://community.webshots.com/album/142616888gPMNvD

IntrepidXJ

NAXJA Member #647

- Location

- Grand Junction, CO

ghettocruiser said:Rev: Hope you dont mind me posting this pic. I found it awhile back in another post about TJ flares. I kind of dig the look of this. Not sure if its yours...if it is, was that top tight? removable? rear window?

taken at winterfest 04 :wave:

IslanderXJ

NAXJA Forum User

- Location

- Avalon and San Luis Obispo

I am going to be putting smaller dia. tubing under the headliner on each sid of the ABCD pillar hoops, welded to the roof, but internal.

I was trying to have the XJ look virtually unchanged from the outside with the roof on. With the exceptioin of some fender triming, quarter panel protection, and the seam between the roof and body.

I was trying to have the XJ look virtually unchanged from the outside with the roof on. With the exceptioin of some fender triming, quarter panel protection, and the seam between the roof and body.

gmars

NAXJA Forum User

Ignore the ridiculous "why not just buy a #### (whatever)" comments. They're the kind of people who just plain SETTLE for whatever is for sale or is typical. Too conservative to even answer.

I'm psyched for your project. Could be freakin cool as hell.

With enough rollbar-ing and proper bracing, you could do whatever you wanted.

I actually saw an older XJ all cut up and modded when I was in Tobago a couple years back. Biggest concern was bird crap! Didn't have the Nikon, back at the house.

Roads sucked, gorgeous views, needed a backseat. Chopped XJ solved the probs!

Good luck. Ignore the conservo cronies.

I'm psyched for your project. Could be freakin cool as hell.

With enough rollbar-ing and proper bracing, you could do whatever you wanted.

I actually saw an older XJ all cut up and modded when I was in Tobago a couple years back. Biggest concern was bird crap! Didn't have the Nikon, back at the house.

Roads sucked, gorgeous views, needed a backseat. Chopped XJ solved the probs!

Good luck. Ignore the conservo cronies.

IslanderXJ

NAXJA Forum User

- Location

- Avalon and San Luis Obispo

Thanks, I would always ather make something than buy it because then I know the quality. Then its the only one in existance, which is always cool.

This project is defintly going to be slow moving ( I'm a college student). Most of the work will be done during the summer, when I'm making more money than I'm spending.

Also will be pulling interior panels soon to take accurate measurements, no cutting anything yet. Will get picks up whenever somethin' gets done.

Just put it in the shop to get the windshield replaced, Put a hole in it with a pine tree at Big Bear, CA. Was muddy, there was technically not a road anymore, and drifting around a corner. just glad i let my girl sleep in, or i wouldn't have her around anymore, lets just say I had to get a new headrest, sorry no pic.

This project is defintly going to be slow moving ( I'm a college student). Most of the work will be done during the summer, when I'm making more money than I'm spending.

Also will be pulling interior panels soon to take accurate measurements, no cutting anything yet. Will get picks up whenever somethin' gets done.

Just put it in the shop to get the windshield replaced, Put a hole in it with a pine tree at Big Bear, CA. Was muddy, there was technically not a road anymore, and drifting around a corner. just glad i let my girl sleep in, or i wouldn't have her around anymore, lets just say I had to get a new headrest, sorry no pic.

MistWolf

NAXJA Forum User

- Location

- Washington

I've actually been toying with the idea of installing a fold down front windscreen from a Wrangler myself. Just haven't been able to work on my XJ last couple years like I've wanted to. This year though, I'm gonna get started. NV4500 is in the shop being rebuilt. But I think I may have to work on my 79 Cherokee first. The AMC 401 needs overhauling

Definitely want to see how that part of your project works out

Definitely want to see how that part of your project works out

IslanderXJ

NAXJA Forum User

- Location

- Avalon and San Luis Obispo

The fold down windscreen from a wrangler won fit the body shape, I pulled my girlfriends off her 99' TJ (she doesn't know shhhh!)while I was running some wiring for some lights and I think it would take more work to make it fit then to just grab some of the TJ/YJ brackets and reinforce mine with some small dia. tube, and tear a seal off a rollover TJ/YJ victim at the junk yard.

As for the seal from the windshield frame to the roof and roof to body, I found this

http://www.airbagit-store.com/product_list.asp?id=1745

I called them and its actually only enough for a MJ, but you can order more pieces.

As for the seal from the windshield frame to the roof and roof to body, I found this

http://www.airbagit-store.com/product_list.asp?id=1745

I called them and its actually only enough for a MJ, but you can order more pieces.

Similar threads

- Replies

- 1

- Views

- 381

- Replies

- 0

- Views

- 390