FatCity

NAXJA Forum User

- Location

- Wildomar, CA USA

Austin brought us his car a couple weeks back for some prep work and changes before the Mint 400 at the end of this month.

Here's a link to the last thread where we rebuilt the rear of the car.

http://www.naxja.org/forum/showthread.php?t=995711&highlight=Austin+1709

He said the whole front of the car felt like it was moving around alot more than it should.

Man! was that an understatment...

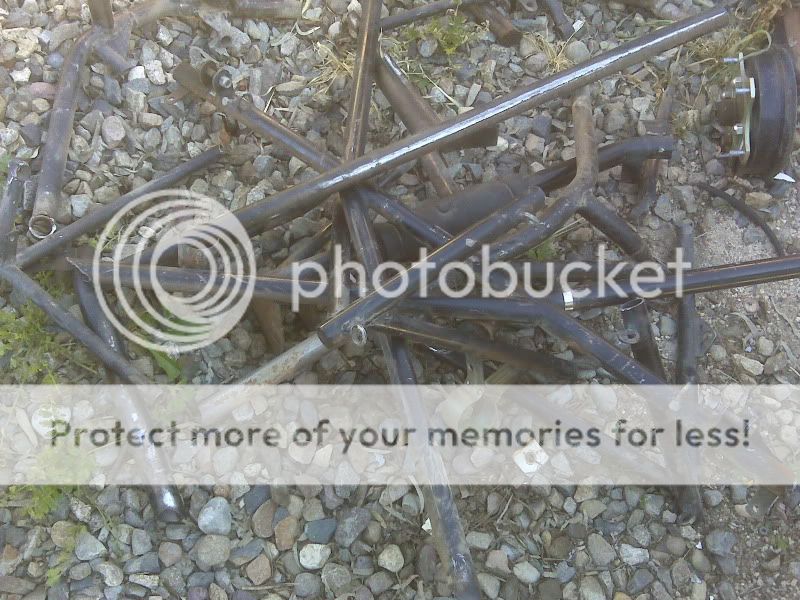

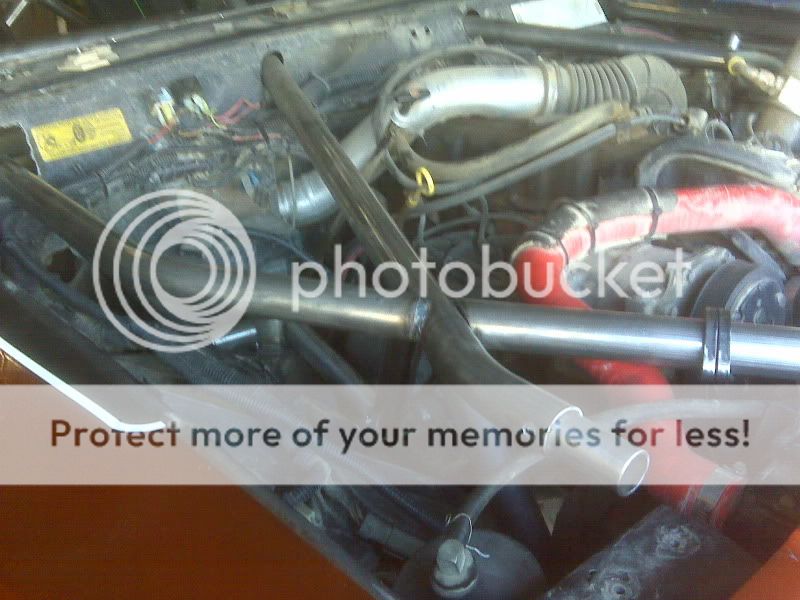

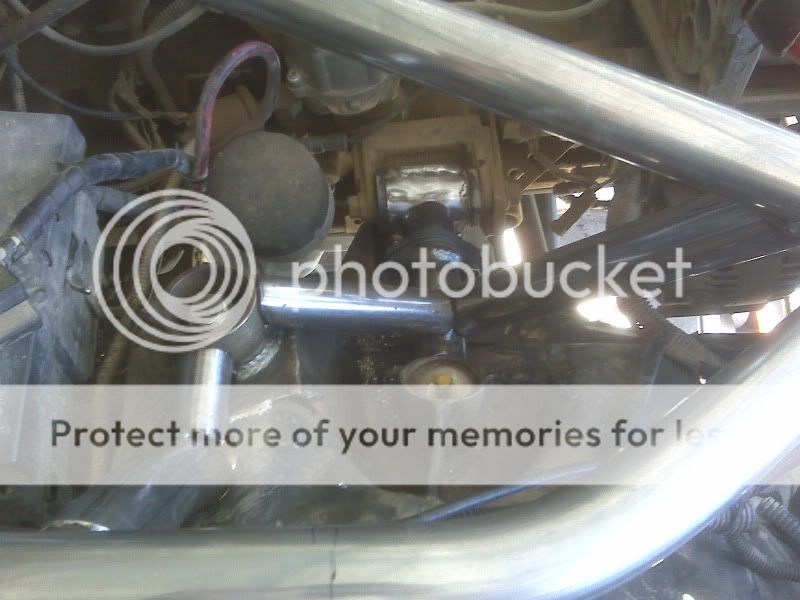

The chassis/cage was literally broke in half! At least 5 tubes were broken, a couple you could see and others hidden in the roll bar padding. The bad news is Austin will miss the Mint 400 this month. The good news is we have the green light to cut out all the cage from front bumper to rear shock mounts and make this a modern Jeepspeed. He'll have a new Fat City car to race in the May day/night race.

Austin will have new BFGoodrich tires, ProComp alloy wheels, Currie Enterprises fabbed F9 rear housing, Currie Ent. high pinion D44 for the 4wd races, Fox quad bypass shocks, Motive Gear and TEN Factory gears and axle shafts, and LighForce lights.

Austin and his dad Ron through a little color on the car before they brought it over.

All tore down and ready for a make-over and prep...

Here's a link to the last thread where we rebuilt the rear of the car.

http://www.naxja.org/forum/showthread.php?t=995711&highlight=Austin+1709

He said the whole front of the car felt like it was moving around alot more than it should.

Man! was that an understatment...

The chassis/cage was literally broke in half! At least 5 tubes were broken, a couple you could see and others hidden in the roll bar padding. The bad news is Austin will miss the Mint 400 this month. The good news is we have the green light to cut out all the cage from front bumper to rear shock mounts and make this a modern Jeepspeed. He'll have a new Fat City car to race in the May day/night race.

Austin will have new BFGoodrich tires, ProComp alloy wheels, Currie Enterprises fabbed F9 rear housing, Currie Ent. high pinion D44 for the 4wd races, Fox quad bypass shocks, Motive Gear and TEN Factory gears and axle shafts, and LighForce lights.

Austin and his dad Ron through a little color on the car before they brought it over.

All tore down and ready for a make-over and prep...

Last edited: